Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

White patches in Chrome Plating

Dear ladies and gentlemen,

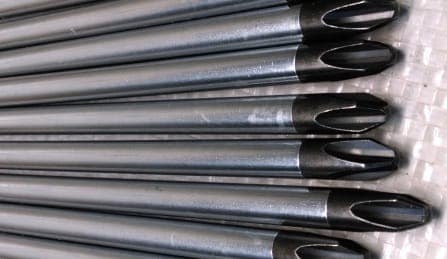

I would like to ask you, would it be possible to give us some advice in this case: Why is permanently during chromium failing?

You can see the pictures.

Thank you for your answer.

With kind regards.

Travnickova Vladimira- Brno Czech Republic

December 21, 2022

A. Hi Travnickova.

Maybe better incoming inspection? I don't think the missing plating is a nickel-chrome plating defect, but bad material or at least not properly cleaned?

But that's only a guess because we have no information at all yet; not even what the substate is nor any data about the plating. It's hard to know if the roughness everywhere is burnt plating, or parts which received no mechanical finishing :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

⇩ Related postings, oldest first ⇩

Q. We get white patches on some of the parts we plate. What causes this to happen?

Bill Blondickplating shop - Chicopee, Massachusetts

2005

|

A. Just on the edges is burning from excess current; but you'd recognize that. All-over is current interruption during chrome; check condition, cleanliness and tightness of all contacts. If spots and splotches in random pattern, it's passive nickel; check for drying between nickel and chrome, grease films on rinses or chrome tank, try to improve rinsing with warmer water or better agitation or longer time or add another rinse. Maybe excessive nickel brightener, try soak for 15-30 seconds in chrome before applying current.  Jeffrey Holmes, CEF Spartanburg, South Carolina A. You have Excess Sulphate in your bath in excess of 150:1 Chromic acid: Sulphate.  T.K. Mohan plating process supplier - Mumbai, India A. Bill,  Popatbhai B. Patel electroplating consultant - Roseville, Michigan A. Your nickel has become passive.  Geoffrey Whitelaw - Port Melbourne, Australia |

Q. To detect chrome burns on a chrome rim...what is the best type of light to use that will make the burn stand out making it easy to detect at an inspection station...

Type of light, kelvin, wattage, etc.

Thank you

Electrical - Kitchener, Ontario, Canada

2005

by Safranek & Brooman

on AbeBooks

or Amazon

(affil links)

A. Hi

Safranek's book has an excellent chapter on inspection stations, including lighting ⇨

Luck & Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. We are plastic part platers. We have white patches/shadow on the part after plating in the Bright chrome (Cr6). For corrective ACTION, we had tried to change the predip solution regularly before chroming process, control the sulphate content in chrome & predip chrome tank, and mix some sulfuric acid in the dragout tank after nickel plating. However,the problem still exists.

Is this problem related to too much wetter in Nickel plating? Or is it due to traveling time that been taken to long between nickel to chrome process making the nickel layer passivate? Or is it related to our DI water pH/quality? Anyone with new idea/suggestion, please help. Thank you.

plating company staff - Malaysia

April 17, 2013

A. Hi Norddin,

Non uniform white patches could due to:

1. Lead contamination in chrome bath.

2. Poor cleaning prior nickel plating.

3. Part dries prior to chrome plating.

Regards,

David

David Shiu

- Singapore

Q. Dear all,

Here what all factors which causes white patches are really found, but is there any effect of semi-bright nickel for white patches? Please help me to sort out this problem and to know about it?

- Bangalore, Karnataka, India

December 23, 2014

A. Hi Chandrashekhar. Sorry, I'm not sure if I'm fully understanding your question. Are you saying the patches form in the semi-bright nickel plating step, but then you go on to bright nickel plating and chrome plating and you can still see them after the other plating steps? Apologies, but I don't quite understand your situation. Please spend several paragraphs on details. If you can include pictures I'm confident that the readers can help you address it. Thanks!

If you are seeking a general discussion of nickel plating issues, like what effects the semi-bright nickel step can have on the final nickel-chrome plated object (with all the ifs, ands, & buts), here is a nickel plating book which should help. The Canning Handbook [on eBay, Amazon, AbeBooks affil links] has a good troubleshooting section on nickel plating too. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Sir, I am working for a rotogravure cylinder manufacturing unit. First time I am facing the problem of "whiteness" in chrome plating. Whenever I start going to flow the current onto the object, it creates big patches and the patches all convert into whiteness on complete cylinder. My chromic acid is 260 gm/lt and sulphate is 1.8 gm/lt. Please suggest what should I do for this?

Gaurav shahgravures - Hyderabad,Telangana, India

February 11, 2015

A. Hi Gaurav,

The problem could due to:

1. High pH

2. Low wetting agent

3. Low chrome concentration

4. Lead, zinc contamination

5. Poor cleaning before plating

6. Parts dry up prior chrome plating

Regards,

David

David Shiu

- Singapore

Q. Hello. I send some photos with white patches on our plated parts. Is this white wash or what is this? Usually it goes away when I add some brightener and wetting agent.

Can anyone tell me what are this white spots on the photos I attached?

Bojan Koren- Bovec, Slovenia

April 25, 2015

A. The rinses between nickel and chrome contain inorganic contamination.

Regards,

Anders Sundman

4th Generation Surface Engineering

Consultant - Arvika,

Sweden

April 14, 2015

A. Check the sulphate ratio. It is common when sulphate ratio is high in the bath.

KP

- Bangalore, Karnataka, India

![]() Thank you for your opinions but I think it's something wrong in the nickel bath because when I add 0.1 mL/L of brightener and/or some wetting agent the white spots usually disappear. We have problems with these white patches only on bright nickel not on matte nickel.

Thank you for your opinions but I think it's something wrong in the nickel bath because when I add 0.1 mL/L of brightener and/or some wetting agent the white spots usually disappear. We have problems with these white patches only on bright nickel not on matte nickel.

- Bovec, Slovenia

A. I have a strong feeling that the bright plating tank/vat may be contaminated with oil hence these patches. Please use scum remover, or use filter paper and swipe over the top of the tank, and use carbon treatment more periodically. Best regards.

Mahendra gargatti- Belgium Karnataka lndia

Q. Dear Sir,

We are facing problem of white patch also. I think problem is generated from semi bright. Because in semi bright, the component is getting bright instead of dull. What can be the reason, please explain?

- bhuj, Gujarat, India

August 16, 2015

! I have seen white staining on chrome plated parts as well. Chemical analysis revealed that they contained lead (Pb) and antimony (Sb) but in particular always Sb. Pb only stains were black. I believe these are contaminants from the anodes used which are commonly made from Pb-Sb alloys.

Hope this helps.

- South El Monte, California, USA

May 28, 2016

![]() Hi Lawrence. Tin-lead and antimony-lead anodes were successfully used for chrome plating in thousands of shops for decades before I entered the industry, and that was 50 years ago -- so I would be shocked if they are the cause of white staining ... but I can't argue with your findings.

Hi Lawrence. Tin-lead and antimony-lead anodes were successfully used for chrome plating in thousands of shops for decades before I entered the industry, and that was 50 years ago -- so I would be shocked if they are the cause of white staining ... but I can't argue with your findings.

There may be something wrong with today's anodes or something unusual about your situation. Thanks for the thought-provoking idea !

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Good day Lawrence.

This white staining reminds me of "white wash". We could buff it out. In my experience, this "white wash" was attributed to organics carried over from bright nickel, and passivation of the nickel plating. High wetters/brighteners are difficult to rinse, and you need to avoid passivation of the nickel plate. I have used a nickel drag out tank, and kept the pH acidic, in an effort to simulate an acid dip. The drag out was sent to waste treatment weekly, as our sludges were sent to refining = $$$$$ in nickel metal. Also, I used the chrome drag out before chrome, but this drag out needs to be also kept clean. Are you using silver oxide? Are you adding barium carbonate as a slurry in water before adding to the chrome?

Just a few thoughts.

Regards,

Aerotek Mfg. Ltd. - Whitby, Ontario, Canada

Water mark issue on chrome surface

Q. We are getting water mark on the chrome plating surface after chrome bath in POP, also sometimes we are getting tiny crack lines on plating surface. Please suggests possible solution to this problem.

Thanks in advance

Exotech Zanini Industries P. Ltd - Pune

June 18, 2017

![]() Hi Sanjay. Please send pictures to mooney@finishing.com for posting here. One person's "water mark" can be another person's "whitewash", someone else's "patches" and yet another guy's "skip dots". Thanks.

Hi Sanjay. Please send pictures to mooney@finishing.com for posting here. One person's "water mark" can be another person's "whitewash", someone else's "patches" and yet another guy's "skip dots". Thanks.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

White layer beneath nickel chrome plating

Q. We are currently getting a hazy layer on our components which is very clear after plating, due to which we are not getting mirror finish.

We get this problems on about 50% of total components loaded on a single flight bar.

We do decorative Nickel & chrome plating.

Our bath composition have returned fine.

The same material if replating is done, the layer seems to go away.

Yogesh Jha

EMPLOYEE - Punjab India

December 21, 2018

Q. We are getting a whitish layer on our components after nickel chrome plating.

This we get on 50% of our parts.

Yogesh Jha [returning]

EMPLOYEE - Punjab India

January 23, 2019

Q. We are getting a uniform whitish layer beneath our Bright nickel & Chrome Plating.

The layer comes off in two cases

1. When we buff the components after plating (but we cannot as it compromises our chrome plating)

2. When prior plating we dip the Components for a minute in Hydrochloric acid (cannot be done for all components compromises Production).

Yogesh Jha [returning]

EMPLOYEE - Punjab India

May 25, 2019

Q. We are getting white patches on our components after bright nickel chrome plating.All our impurities are within range, we have chrome activation prior to chrome plating after nickel.

The problem is that we are getting white patches after bright nickel plating. Our bath chemistry is fine, all impurities are within limits, brightener, leveler concentration level is also within prescribed range. (All we had checked with our present & previous Chemical Suppliers)

Our Process is : Soak Degreasing - anodic cleaning - acid pickling (H2SO4 + HCl) - Anodic cleaning 2 - Acid Dip (H2SO4) - Strike Nickel - Semi Bright Nickel - bright nickel - Cr activation - Chrome Plating.

Please need help on above situation.

July 19, 2019

EMPLOYEE - Punjab India

A. Hello Yogesh,

When you say the impurities have been checked, would that be metallic impurities only? As you may know basic analysis will give you bath constituents, and 3 or 4 metallic impurities such as copper, lead and zinc. Organic impurities are normally not analyzed in routine bath analysis. When was the last time the bath was carbon treated? The last shop I worked for we would carbon treat when the bath turned a dark green color. Leave a bath sample of the untreated bath aside, then draw another sample after 4-6 hours of carbon treatment. The treated beaker sample should produce a clean emerald green color that is fairly translucent. You will notice a big difference in the color and clarity. Our supplier nor independent labs we worked with could not give us organic impurity levels because they were not set up for it. The second possible cause I would investigate would be the wetting agent concentration. If you do carbon treat consult your supplier so they can advise you of any additions to be made before you begin plating. The carbon treatment can pull out important organic ingredients. Hope this helps.

[But] I have to say I am totally confused with your post. You state you are getting the whitish haze after nickel and chrome, same effect under the nickel and chrome, and also after nickel plate. Where are you actually seeing the haze?

Electronics plating - Winston-Salem, North Carolina USA

Q. Thanks Mr. Baker for your suggestions.

We have already carbon treated our bath when we faced such problem. To have a clear picture of our problem I have posted pictures in last thread.

We have noticed one thing that the problem is not all on components as sometimes we get 30% material ok and sometimes we get 70% ok but never 100%.

We tried out Hull Cell also but results were absolutely fine. We have chrome activation prior to chrome plating so this is not passivation I guess.

Please provide some help.

SHOP EMPLOYEE - Punjab India

![]() Hi Yogesh. You did indeed post pictures, but I think the problem Mark references is that but your postings seemed to imply that this whitish look was present earlier in the process, possibly before any plating, or possibly after nickel plating but before chrome plating.

Hi Yogesh. You did indeed post pictures, but I think the problem Mark references is that but your postings seemed to imply that this whitish look was present earlier in the process, possibly before any plating, or possibly after nickel plating but before chrome plating.

Can we call that a misunderstanding, say that the pictures are all after chrome plating, and that you do not have evidence of any whitish look until the wrenches are chrome plated?

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Sir,

The pictures I have attached are after bright nickel chrome plating.

All I want is to remove this whitish appearance I am getting, as it is causing a lot of problems.

We have noticed one thing that if prior to plating process we Dip the samples in 10% Hydrochloric Acid and Load material for plating (that is regular process from cleaning till final) we get absolutely fine results.

Shop Employee - Punjab India

February 24, 2021

Q. Hi, currently our company is facing white patches issue on nickel chrome plated part. The white patch actually looks like this:

Which aspect that can be possible as the root cause of this kind of white patches? Thank You.

Rizky Putri- Riau Indonesia

Q, A, or Comment on THIS thread -or- Start a NEW Thread