-----

Gold Recovery for Dummies? p2

< Prev. page (You're on the last page of the thread)

Every environmental organization the world over is begging people who don't operate legitimate refineries not to try to recover the gold from old electronics; there are dozens of youtube videos from them explaining why. But we don't believe in censorship, so proceed at your own (and the planet's) risk...

PGC electrowinning/recovery

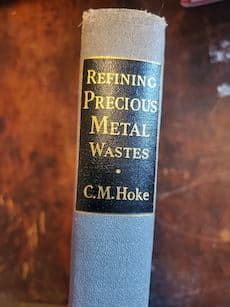

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

Q. Good afternoon ,

We tested the effectiveness of the PGC recovery through the electrowinning process but we are having complications; we used our existing equipment to recover 446.7 grams of PGC , which was dissolved in 35.4 liters of water and processed for 4 hours. Seeing no apparent results, we added 150 g of sodium chloride dissolved in 800 milliliters of water with the idea of breaking the link of cyanide -- this process took 3 hours, the color of the solution changed to yellow and the cathodes changed their color to copper. Because of this, we assume that the brass was being attacked; we added KCN 705 grams dissolved in 1.7 liters of water and left for 7 hours, but so far there is only a small gold layer on the cathode.

We do not know if they could have made another compound which is not compatible with the recovery process; we think that may have formed AuCl4 gold tetrachloride, sodium cyanide, PGC in solution, or sodium hydroxide .

The main question is: which compound is formed by adding sodium chloride to dissolved PGC? The result of this reaction? And how to recover the gold contained in it?

We appreciate your kind cooperation.

- Bogota, Colombia

January 21, 2014

A. Hello Daniel,

Your first run with PGC and water would not work at all because there are not enough "throwing" salts in the PGC to plate with. I don't know what, if anything, sodium chloride would do to hamper your efforts on the second run. What I do know is that you will never get your money's worth trying to electrowin gold. You will never plate all the gold out of solution because once the concentration of gold drops to a certain level, the current efficiency suffers dramatically. This matter is worse if you don't adjust the current on the rectifier accordingly as you go along. when you had PGC in salt form you could have easily sold it back to the supplier, or a local shop that plates gold. This is easy to do especially if the PGC is still sealed in its container. Now you have choices to make that will cost you more money because you will have to have it refined. You can drop the gold out of solution with aqua regia, or run it through a resin column designed for gold recovery or use a gold bug. Sorry, I cannot explain precipitation with aqua regia because it should be left to professionals that have done it before, and have the proper safety equipment and facility to do it in.

Process Engineer - Malone, New York, USA

Q. Thanks for your answer, we already made the aqua regia procedure,IF SOMEONE WANTS TO DO THIS PLEASE BE CAREFUL: CIANHIDRIC ACID [hydrogen cyanide] IS PRODUCED IS EXTREMELY HARMFUL.

200 ml were taken, by titrating the amount of free cyanide was determined. Based on this a few drops of hydrogen peroxide was added to remove free cyanide, thereafter rechecked and with only a single drop of liquid changed color. Then added 100 ml of aqua regia, let it warm up until boiled over, then we add urea to adjust the hp, and then 5 grams of sodium metabisulphite dissolved in 20 ml of water to precipitate the gold, allowed to decant. Black colored precipitate appeared which was filtered and melted but did not show gold, according to the concentration should be 1.6 grams.

We are still having problems :-(

- Bogota colombia

A. Hello Daniel,

If you refer to the posting on this thread dated from C Wilford, it will give you step by step instructions.

process engineer - Malone, New York

Is potassium cyanide the best electroplating substance?

Q. Hello. I am getting into the electroplating business. I actually have tons of computers and someone told me in order to get off the gold from within the computer components, I could get potassium cyanide. But from my findings and comments on this site, it seems expensive. So I want to know if that is the best way to get off the gold. Any other suggestions? I will like to get answers or someone who can sell potassium cyanide cheap.

Jones Moorebuyer - Austin, Houston, Texas

November 21, 2014

A. Hi Jones. Potassium cyanide is one of the fastest acting and most potent poisons known, and you need to be wary not only of ingestion, but accidental acidification which produces deadly cyanide gas. Please make sure you have enough chemical knowledge, and a secure and well-equipped enough industrial facility to deal with it safely. The grass is always greener on the other side of the fence, and the path to riches always seems to involve the fields which we know little about. Good luck, but please don't buy potassium cyanide until you have at least completed a haz-mat training course.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I got quality potassium cyanide from an online store. They gave me instructions on how to handle potassium cyanide. I am still undergoing an intense training on how me and my team can use the product on the vast room of spoiled computers I have. Thanks again. Any other suggestions will really help me on how to handle it and how to do my electroplating.

Jones Woodson [returning with different name]buyer - Austin, Houston, Texas [returning]

A. Hello again Jones.

silly :-) We told you this stuff was dangerous! And now you've gone and forgotten your name while you think you're posting from Texas when your IP address says that you're on a different continent ... we hope these toxic chemicals haven't turned you into a mad hatter :-)

The next suggestion after you've achieved haz-mat certification, but before you do any de-plating and instantly lose track of the gold content, is: "How will you measure the amount of gold on the spoiled computers?". There's no point in trying any recovery method until you can accurately track the gold because you'll have absolutely no idea how much you're just pouring down the drain at the various steps. Do you have good thickness measurement equipment so you can accurately track the incoming gold against the gold analysis at different steps, and the final amount of gold recovered?

Be careful. Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hello, I've acquired a property with a vast amount of computer components. The components were originally purchased at a NASA auction, so they have a high amount of precious metals. I've attempted selling, but since the parts are antiquated there is not much interest. So I've been attempting to recover some of the precious metals.

I've been using a mix of 50/50 32% hydrochloric acid and 3% hydrogen peroxide. I've been extracting excess copper with electro-less crystallization with stainless steel.

After extraction, I'm having a lot of gold, and I'm assuming other precious metals in suspension. After washing, I've been using a surfactant and still have inadequate precipitation. Is there an easy cheap flocculant to knock the gold out? And will I still have silver and other metals dropping out as well?

Thanks,

Kevin

Hobbyist/Recycler - Merritt Island

September 19, 2015

A. Hi kevin,

basically which flocculant do you use in gold deposition?

I can definitely solve your problem only if you share which process you applied?

Is it flocculation process or precipitation of gold?

cac admixtures - Mumbai, India

Ed. note: Thanks Bhupesh, insightful comment! Flocculants don't settle dissolved salts, they only help settle precipitated solids.

Q. Hello,

I have been doing aqua regia, but the gold that came out is not pure 99%, it is always 97-98%. How do I increase the purity?

- Surabaya, Indonesia

October 30, 2015

A. Hi SAPI,

You are doing something wrong in your process; after aqua regia process you should get minimum 99.1 to 99.5% gold purity as per my experience.

CAC admixture - Mumbai, India

Hydrazine hydrate concentration for gold recovery

Q. I have a job of gold recovery from cyanide solution, waste scrap of jewellery, etc. I have a problem with this.

When I complete aqua regia, I add a little amount urea. After that I add hyrazine hydrate solution 80%. I dilute it with 100 ml hydrazine and 400 ma water. After addition of it, precipitation occurs, but gold that precipitates is in the form of dust, not in a spongey big ball.

What the problem is I can't understand.

And when I filter it with filter paper some amount of gold dust filters out at bottom of flask. So please help me what is the problem I'm facing.

- rajkot, India

May 3, 2016

A. I've been refining for 50 years and I have never worried about what the precipitated gold looked like. As long as I got it all out (as confirmed by testing the solution with stannous chloride), I wasn't concerned about the appearance. It always looks a little bit different, even if you split the solution and precipitate the 2 halves separately.

Chris Owen- Nevada, Missouri, USA

A. Dear sir,

I had gone through your problem; while forming nuggets, your water temp should be low. Maybe your water quantity is low, so you're pouring hot melted metal increases the water temp.

And rotate your water in clockwise direction and pour your melted metal in anti-clockwise direction.

CAC admixtures - Mumbai, India

Q. My question is about gold recovery. I am facing a problem during its final stage. When I make aqua regia it becomes muddy. After that I filter it with paper. Then also it becomes muddy. Now I add urea and hydrazine. So gold becomes precipitated. But when I filter the solution precipitated gold also filters out. I don't know what is the problem. Please help to solve it.

Ritesh Parmar- rajkot, India

May 25, 2016

A. Hi, Ritesh Kumar

I can solve your problem. As per my past experience, you are recovering gold from either polish or carpet burned dust. This problem will not occur in filing dust.

Main root cause is addition of urea; don't add urea and check. Urea lowers the acidic pH. Hydrazine also is a base pH.

So lower concentration of gold, don't add urea.

CAC admixtures - Mumbai, India

Q. What would be the easiest way to recover gold from concentrate and with WHAT chemicals?

TRACY NEUWERTH- mogale city, SOUTH ARICA

June 4, 2016

? Hi Tracy. Please pardon my ignorance and tell me exactly what "gold concentrate" is.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Hi Tracy,

Gold concentrate may be gold dissolved solution.

Ferrous sulphate

⇦ on

eBay or

Amazon [affil link] is better chemical for reducing gold.

CAC admixtures - Mumbai, India

Immersion Gold on Gold Plating

Q. In immersion plating with multiple different ions competing with gold ions by first extracting the ions above gold on the electromotive scale with say lead. Then plating out the gold ions using gold plated metal or pure gold strips? If it will work would it just plate until the surface is covered or would it continue to plate until it exhausts all the gold ions in solution.

Chuck ChaseHobbyist restorer - Baker City, Oregon, USA

June 16, 2017

A. Assuming the series is written so the more reactive metals (Al, Mg, etc) are at the top of the list (some lists are reversed), any metal that will drop out the metals between gold and the metal used will also drop out the gold at the same time.

Your best bet is to use copper, which is only slightly above gold on the scale. It will drop out gold and anything below it (Ag, Pd, Hg, etc.) but will not drop out anything above copper.

The general rule is: a metal will drop out (cement) all metals below it. However, the metal used must be able to dissolve in the particular solution that is used. For example, it is quite common to use copper metal to drop silver out of a nitrate solution. For each 3.4 grams of silver that is dropped out, 1 gram of copper will dissolve into the solution.

- Benton, Arkansas, USA

Q. Hi,

Is it possible to deposit a selected metal at the cathode from a sludge containing Au, Ag, Cu, Fe? Knowing that the cathode and anode are made of graphite.

As an example: If I solely want to plate the cathode with gold (E0 Au+/Au = 1.69V) in order to recover it, will the application of a constant overpotential of -0.2V work?

assuming that E0 of Ag+/Ag, Cu+/Cu, Fe2+/Fe and Fe3+/Fe are 0.79, 0.34, -0.44, -0.04V), It seems to me that only gold will be reduced hence separated. Am I right?

Thank you.

Pall

- Quebec, Quebec, Canada

July 6, 2017

A. Hi Pall

You do not say how you propose to get your sludge into solution but assuming that you do it should be possible to separate the metals electrolytically provided there are no complexing agents present

The problem is to control the overvoltage and to do this requires a potentiostat that is both expensive and requires some skill,

I would suggest that the most practical course would be to sell the sludge to an experienced recovery company.

Geoff Smith

Hampshire, England

Q. I am processing gold ore using NaCN or sodium cyanide, but this certain gold ore is really giving me a big problem. During processing the gold-copper ore it eats or consumes too much cyanide because of the high copper content. At the end of the process I've lost; I expend more money than I recover due to high cyanide consumption.

I read some article about using H2SO4; and also know as sulfuric acid can help to solve my problem.

I try to soak the gold-copper ore with the sulfuric acid to dissolve the copper.

But still not working well.

I also read a certain procedure using flotation but I actually can't understand it due to lack of education, and lack of chemicals and equipments.

Can anyone help me and can teach me regarding this matter.

Student - Manila, Philippines

July 30, 2017

A. Hi Jason. I can't help you with an improved process, but I can tell you that if you don't know what you have, no one can suggest whether any process will be economically viable. Has anyone assayed this ore to give you an idea how much copper, how much gold, and how much other stuff is in it? Without that I doubt that you can get anywhere even with education, chemicals, and equipment because there will always be ores with too low a gold content for practical processing; whereas, possibly, viable copper recovery may be achievable. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. How do I check acid solution for gold? Had a friend doing gold reclaiming in my garage, he took off, left me with a container, so I need to check it: it's green, dark green (was told darker the better). Help please.

daniel barnum- millington, Michigan usa

October 4, 2017

A. DOES THIS (ANSWER) ANSWER YOUR QUESTION?

1. Place impure gold to be dissolved into a glass or plastic container.

...

...

16. Once melted, the gold will again take on the appearance of metal. If you've followed the instructions carefully and used filters, the gold will be 999.5 % Pure with virtually no losses.

(SEE ANSWER BY C. WILFORD, ELGIN TEXAS USA, January 7, 2012)

C GONZALEZ

HOBBYIST - RIVERSIDE COUNTY CALIFORNIA US

November 25, 2024

Q. I have some (rocks) ground to dust. I would like to refine the (gold/silver/palladium/Pt). I have used Ar. Aqua Regia I would like to use Nitric acid and Al to reduce the Pd.

Can you help me?

Thank you

- spanaway, Washington USA

October 13, 2017

A. Hi, for palladium recovery dimethyl glyoxime (DMG) is used.

Thanks,

CAC admixtures - MUMBAI, Maharashtra, India

Q. Hi I have a scrap gold from computer components containing small amount of copper. If I were to put an electronic charge though this mixture in the same way as you would in copper plating is it possible to remove the copper without affecting the gold? Thanks.

Sid strong- London England

October 1, 2018

A. If I understand your situation correctly, the answer is no.

What is the source of the metal? What form is the metal in now? Powder? Bar? What? What is the approximate weight?

- Benton, Arkansas, USA

Q. Hi, my name is Charles. I have some metal alloy plates and will pass on a scratch test with 14 karat gold testing acid and metal detector too. Is this possible and how can the gold be extracted?

Charles Nelson- Tulare California usa

June 9, 2019

A. Hi Nelson. When you say "metal alloy plates" that have passed testing, it sounds like you are describing solid metal, not a plating. If you are confident enough in your testing to go further, I would take one of the plates to a scrap metal dealer who has a scrap sorter ⇦ on eBay or Amazon [affil link] X-ray fluorescence machine so they can tell you what you have. Because, unless you are highly experienced it is usually impractical to attempt to recover gold without knowing what you have -- there are several sequential steps in the process where you separate the wheat from the chaff and you'll have no idea at which steps you threw away how much of your gold as waste if you don't know what you started with. Good luck :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. How does one get the gold out of Aqua Regia?

Philip BadenhorstMining - Swakop, Erongo, Namibia

June 11, 2019

Recovering Gold and Palladium from test strips

Q. My name is Kevin, What to do with 1 Million gold, and 500k palladium test strips? I even have the solid gold and palladium full uncut sheets ... about 100 pounds in all. Should I take it to be processed? Or try this myself? I'm a laser engineer who designed the lasers to originally cut the strips, not a chemist. Thank you

Kevin Davis- Hazel Park, Michigan USA

March 11, 2020

A. If you actually have 100 pounds of pure gold and palladium, you have a substantial fortune.

Check with a reputable precious metal refiner. You can retire to the French Riviera.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

I have A Clear green so what am I not doing to get the gold from there

- Tucson Arizona US

May 21, 2020

Q. I bought 5 lbs of smelted computer parts, smelted with borax ⇦ on eBay or Amazon [affil link] . If I repeat smelting with borax will it get any more pure? It now tests at less than 9%

mark gibson- calexico california

May 23, 2021

A. DOES THIS (ANSWER) ANSWER YOUR QUESTION?

1. Place impure gold to be dissolved into a glass or plastic container.

...

...

16. Once melted, the gold will again take on the appearance of metal. If you've followed the instructions carefully and used filters, the gold will be 999.5 % Pure with virtually no losses.

(SEE ANSWER BY C. WILFORD, ELGIN TEXAS USA, January 7, 2012)

C GONZALEZ

HOBBYIST - RIVERSIDE COUNTY CALIFORNIA US

November 25, 2024

Q. We are working on e-waste recycling using aqua regia solution but because of lack of information we added more urea in it and also more smb. Now when we look at our solution after one day we found that a lot of smb is collected in the bottom. When we try to melt that in order to obtain gold precipitate from it, it is taking lot of time and upon heating a crystal starts to form. Is there any other way to separate smb and gold? Or any idea how we can get optimum benefit? We are school students.

Anikesh singh

- Kosamba Gujarat

June 4, 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread