Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Actual surface area of a rough substrate?

2004

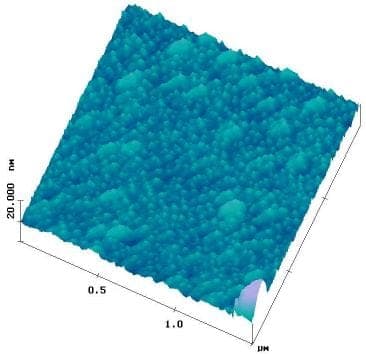

Is it possible to measure the actual surface area of a rough substrate? I have data of different points.

Thanks in advance.

Poritosh Roystudent - Calcutta, India

A. I'm no expert on the subject, Poritosh, but consider...

After fractals became an interesting topic, it was generally conceded that a coastline looks generally the same, i.e., has the same "roughness", regardless of magnification or scale of the map. If you are looking at a map and say "this segment of coast looks to be xx long", all you have to do is look at it under higher magnification and you find that you greatly underestimated the length of the segment. Look again under still higher magnification, and you find that you made the same mistake again. Ad infinitum, or at least until the point where quantum phenomena render the concept of length meaningless.

Similarly, although we're tempted to estimate the surface area of the numerous generally hemispherical humps in your scan, if we were able to zoom in 100X on one of those humps, I think we'd find that it had numerous humps on it as well; ad infinitum.

Being uneducated in the matter, I'd consider the "actual surface area" to be a meaningless term, although I would concede that "estimated surface area at 100nm resolution" or something like that could be a meaningful term.

I tried to answer a student question . . . Now I get to sit back and have people tell me how wrong I am :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2004

Q. I also am no expert in this...

I agree with your explanation of ever increasing magnification (I think I first read this in a James Gleick book) and a meaningless interpretation of "actual surface area;" but there must be a way to figure the EFFECTIVE surface area for a particular application, such as air or water moving across a heat sink fin. I have had trouble recently trying to find this information, which led me to the finishing.com site.

If you have any info on the effective % increase in surface area due to roughing (I've seen it referred to as "rippling") I would be most grateful.

- Herndon, Virginia

2005

+++++

A. As I say, I don't know the answer to the surface area query. But I do know the answer to a related query (the "surface area" of the anode material inside a perforated anode basket for electroplating), and it might provide philosophical food for thought if nothing else: you use the dimensions of the basket rather than the surface area of all the nuggets within it...

As a thought experiment, if you are having a very large party or event, you need to consider not only how many seats are in the room, but the size and number of doors into the room. The area of the doors is critical and is easy to calculate, whereas the area of all the fabric on the seating surfaces may be impractical to calculate.

Similarly your heat transfer calculation can be based on the roughness of a surface, as that changes the turbulence of the flow, without your having to calculate the surface area at each possible magnification. I've been out of school and away from heat transfer and fluid dynamics too long, but doesn't Reynolds Number tie in to this roughness and enable the kind of calculation you want to do, even if some empirical work needs to be done on it?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Reynolds number as a roughness measurement for grit blasting

Q. We perform grit blasting on inner surfaces of long tubes and I am trying to find a parameter that allows standardizing the process when, for example, internal diameter and length are changed. Is Reynolds number a good parameter to do it?

Blasting different tubes to the same Reynolds number gives the same results?

Thanks

- Buenos Aires, Argentina

June 1, 2015

A. A beam of (may be laser) light incident on an ideal flat surface is reflected as per the laws of reflection we learnt in school. The reflected light forms a nice well defined spot on a screen. This is called specular reflection.Now if you make surface slightly rough the spot on the screen is not so well defined. As the surface roughness increases the spot becomes larger and gets smeared more. A stage would reach when the intensity across the screen is almost uniform. This is diffuse reflection. By measuring the distribution of light intensity across the spot it might be possible to quantify the surface roughness and perhaps the surface area. I would not be surprised if this idea has already been implemented.

H.R. PrabhkaraBangalore Plasmatek - Bangalore, Karnataka, India

June 2, 2015

Q, A, or Comment on THIS thread -or- Start a NEW Thread