Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

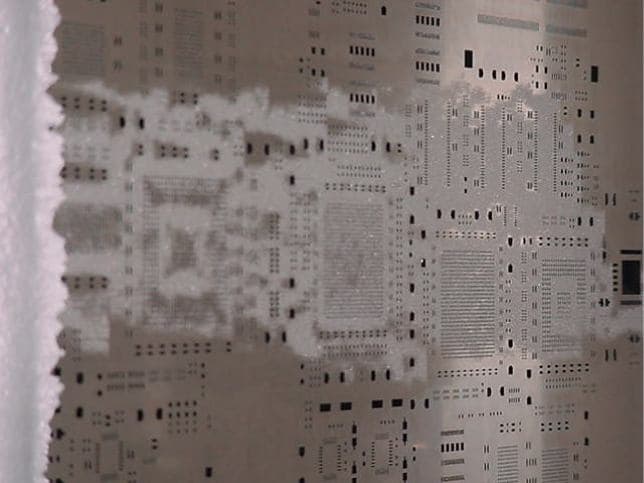

Intermittent deposit on electroplated nickel surfaces

We manufacture solder paste stencils using nearly pure electroplated Nickel 2 to 10 mils thick ( normally 4 to 6 mils ).

Intermittently, solder paste ( regular and lead free ) will form a hazy sticky hard to remove layer on the nickel.

Any ideas why or how to prevent this or remove it.

Thanks

Ronald Tripp- Johnson City, New York, United States

2004

First of two simultaneous responses --

As a preventitive , experiment on a scrapped mask- get it a clean as is possible and then bake it for an hour at 600F in a air atmosphere. It should turn it to a gold color. The nickel oxide is very resistant to solder sticking.

James Watts- Navarre, Florida

2004

Second of two simultaneous responses -- 2004

The solder is probably sticking because of the effects of flux. You may try passivating the nickel with something like a dichromate dip or electrolytic layer or even dipping it in a strong solution (say 200g/l) sodium metabisulphite. It may just work...

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

Ronald

Wow my home town, My grandfather built the archs at each end of town . Anyway looks like a non conductive material did not get cleaned. Looks like oil.

Chris Snyderplater - Charlotte, North Carolina

2004

Q, A, or Comment on THIS thread -or- Start a NEW Thread