Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

How do I stop copper oxidation?

Q. I'm refinishing a 60's hanging lamp with many copper shade parts like fins. The pieces were/are painted white on the inside and the outside is normal orange copper color. They were encrusted with a million years of nicotine and had a thick coating of some sort of finish on them. I brush cleaned some, dipped some in paint remover, polished some, and lacquered some. No matter what I do they are oxidizing into black patchy things! How can I keep them 'orange'? I thought the professional cleaning and lacquering would stop this but it hasn't.

Thanks.

- pittsfield Massachusetts

1999

A. Hi Tom.

There may be something wrong with your cleaning and lacquering process. I don't know what exactly, but if the parts are cleaned so that they are 'orange', and there are no residual contaminants on the surface, and then they are properly lacquered, I think they should stay 'orange'. You might talk to G.J. Nikolas [a finishing.com supporting advertiser], specialists in this field, who offer lacquers customized to the particular need. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

1999

A. I haven't tried it yet, so I don't actually know how good it works, but Permalac [adv: Permalac on eBay]. Do a search on that, and that is supposed to be good for all metals, outside, including sea spray and UV for 10 years (personally I'm looking for something to cover the copper I will be using in an "L" shaped bartop (8' x 4') that will also have an Envirotex Lite [affil links] coating over it, I just don't want the copper to start to green up a few years down the road when the only fix will be to redo the bartop itself. I believe I will be ordering this.

Erik Levasseur- East Coast

April 23, 2010

Q. Several members of my jewelry class and I are interested in anything besides jeweler's lacquer that one can use to prevent copper from darkening. In addition, is there anything that can preserve a deliberately colored piece of copper without changing the colors? By this I mean, I have deliberately fire scored copper to get an amazing range of colors, but the minute you put jeweler's lacquer on the piece, the color changes. If anybody has any suggestions, I would appreciate hearing them

Carla V. Echandi- Omaha, Nebraska

2007

Q. I am currently building a copper sculpture out of half inch copper pipe. I am nearing the end and would like to know if anyone has any information regarding how to properly clean copper for clearcoating. Also, is there a good product out there that works to clearcoat copper and keep the shine and pipe from oxidizing?

Mike Lawlorproduct design - Poughkeepsie, New York

2007

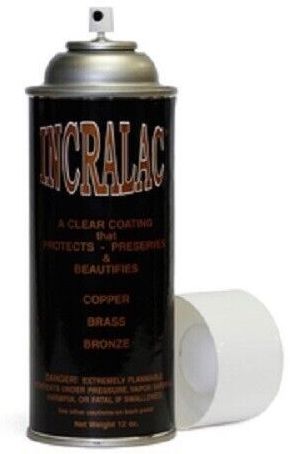

A. Hi Carla and Mike. Benzotriazole ⇦ this on eBay or Amazon [affil links] is a good temporary tarnish preventer for copper, and applying it before the lacquer may help keep it bright. I think some lacquers like Incralac ⇦ this on eBay or Amazon [affil links] or Permalac [adv: Permalac on eBay] have benzotriazole or similar preservatives in their formulation.

Carla, unfortunately there is probably a second problem for you. Yes, all lacquers greatly detract from the pretty colors of heat oxidized copper. I am not a hobbyist in that field, but the reason is that, while some of the colors may be actual pigments, many of the colors are diffraction colorations caused by very thin (partial wavelength) refractive films of transparent oxides or oils (like the rainbow sheen of a drop of oil in a water puddle). When this transparent film is coated with another transparent film, the combined thickness is not partial wavelength anymore and they naturally lose their refractive capability. I think you will find letter 2662, "Preserving heat coloring of copper when clear coating" interesting. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. I notice several questions about stopping the oxidation process of copper. I worked with copper exclusively as an artist for several years and found through trial and error that aerosol polyurethane works very well. Great care must be taken in applying it so that it does not spot or puddle, but I have an oxidized painting on sheet copper in my dinning room that is 8 years old and still lovely burnished copper. Chemically, it literally smothers the surface instantly denying oxygen. A clean surface is a must, as is a uniform and complete application. Missed spots, however small will eventually discolor. I hope this is helpful to some.

Christopher Ricoartist - Clinton, South Carolina

October 2, 2008

?? Chris, You suggested the Aerosol Polyurethane; can this be used on an outdoor application with the UV rays? Will it peel on gutters?

Regards

- Millis, Massachusetts

February 28, 2010

Q. My copper ring is turning my finger green/blue. I got married a week ago and instead of buying rings, we had them made out of copper wire we bought at a hardware store. They came out great but turns out that the ring seems to be oxidizing where it meets my finger and turning it green/blue. First, is this dangerous? Second, what can I do to stop this from happening? Thanks for your help. By the way, my girlfriend's finger has not been turned green/blue by her ring. It is also not as tight on her finger.

Richard Gilstudent - Chicago, Illinois

2007

A. People wear (and swear by) copper bracelets, and a few even claim it wards off arthritis, so I'd say it's not dangerous, Richard.

But the rings should probably be periodically lacquered to keep them looking good and prevent the greening. If you don't have

brass lacquer

⇦ this on

eBay

or

Amazon [affil links]

for the whole ring, you could try clear nail polish on the parts that touch skin perhaps.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

Q. I make chainmail jewelry and I want to find a way so that the bronze links on my pieces don't tarnish quickly. Any home concoctions or products that will prevent the aging of my rings?

Christopher WrightArtist - Beach Park, Illinois

August 30, 2010

Q. I am new to the jewelry business. I am buying and selling jewelry wholesale and would like to know if there is a lacquer or coating I can apply to all finishes. If not, how can I tell what the underlying metal is to coat it appropriately? I have been using clear nail polish but I would like something more long term.

Kiah SaundrieWholesaler - Memphis, Tennessee, USA

March 12, 2012

A. Sodium silicate is a useful water soluble substance for creating a gas proof seal on most metals. It belongs to a family of chemical compounds known as water glasses (

⇦ this on

eBay or

Amazon [affil links]

).

A common use for sodium silicate used to be for preserving eggs. It works by bonding to the calcium in the egg shell and forming a gas tight seal, which prevents oxygen from passing through the egg shell and allowing the egg to go rotten.

Sodium silicate readily bonds to most metals, BTW, how many of you know the element calcium in the egg shell is also a metal? Check out Sodium silicate on Wikipedia or Google.

I suggest that you protect your sodium silicate oxygen barrier with a tough and durable vanish, or lacquer.

I hope this helps someone.

Picture framer - Newton Abbot, Devon, England

March 24, 2012

Q. I am an artist working in Hawaii where I am dealing with salty air and humid temps while working in copper. I noticed my copper has tiny spots on it which I try to "sand/buff" out and the copper gets very shiny. But, in a days time' the spots are back. Also, I am using a torch for coloring and putting in images with hand tools. Now I need a product that coats the copper, makes it glossy and stops the oxidation. Any ideas out there? Thanks!

Jenny David- Hilo, Hawaii, USA

May 21, 2012

Q. Is it possible for an aluminum part that has been plated with acid copper to oxidize after it has been coated with a clear spray lacquer? I'm referring to the plating and not the substrate.

Robert Curry- Portland, Oregon, USA

April 12, 2013

A. Robert,

Yes, very possible. Did you apply Zincate? It wasn't just Cu on clean aluminum was it? Assuming you used a great process with a nice undercoat and did all kinds of testing I would look at condition and rates. In other words, supposing the process was followed and it is a known good process, I would be sure that the parts were dried overnight and that the clear coat was applied on ambient temperature parts.

If the clear coat looks great and there is a problem underneath it then I would suspect the plating process was not correct and the problem could be anything like contaminated baths but often it is a lack of rinsing and drag-out. If a drop or two of the previous chemical is still on the part and not rinsed off, it will cause a small void and after plating imperfections may not be visible unless heavy testing is done including destructive testing. Good luck.

Blake Kneedler

Feather Hollow Eng. - Stockton, California

July 12, 2013

Darkening of copper plated aluminum parts after clear powder coating

February 25, 2014Q. I have a customer that want some aluminum parts copper plated and powder coating clear coat, so I tried the following

double zincate

copper plate alkaline

buff

thoroughly clean with solvent

dry with air as fast as possible in order to avoid lost of brightness

powder coat

bake

And I was worried about the cleaning, but the problem was that the first parts that I painted were darker than the last ones -- so the question is how do I avoid this darkening of the parts? I think they get dark due to the natural darkening of the copper due to exposure during the time we have to wait to complete the batch, before baking.

- Bucaramanga Santander Colombia

Q. I have an old copper jug that I have used the flour, salt and vinegar

⇦in bulk on

eBay

or

Amazon [affil links] paste method for cleaning. It works well until I rinse off the paste residue, then immediately oxidizes before I can even think about lacquering the surface.

Has anyone tried a soft beeswax polish for protecting the surface from air? I find the look of lacquer a bit harsh.

Thank you for any advice you can give.

- Westwood Massachusetts USA

February 25, 2015

A. Hi Felicity. Vinegar & salt is very people friendly but it's exceptionally aggressive on copper, leaving a raw and quickly oxidized surface. After you've cleaned it this way, I'd suggest immediately following it with any commercial product because they are much milder and may include preservatives. Brasso ⇦ this on eBay or Amazon [affil links] should be fine. Then you can finish with beeswax ⇦ this on eBay or Amazon [affil links] if you like, or a matte lacquer.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

February 2015

![]() Thank you very much, Ted. I shall follow your suggestion and try the Brasso

⇦ this on

eBay

or

Amazon [affil links] . Best, Felicity

Thank you very much, Ted. I shall follow your suggestion and try the Brasso

⇦ this on

eBay

or

Amazon [affil links] . Best, Felicity

Mrs. - Westwood MA USA

February 25, 2015

Q. Hi,

I did a restaurant for a client where all the tables are of polished copper and a protective lacquered substance. Even-though we have under plates sheets, the hot plates are leaving grey-black stains on the copper. What might be the solution to completely isolate the copper and protect it for turning grey-black?

Is it possible to fix the actual damaged tops?

Imad

- Beirut, Lebanon

May 18, 2015

Q. Hello all. Trying a metals project with phototransfer and etching on copper. All looked great.....until trying to seal it. Was told Kryon clear was an option. 2 minutes after spraying, the entire piece resulted with a cloudy film. I was able to scrub it off and reapply my images, but am bummed because my piece is to be outside. Any suggestions? I saw Rustoleum sells a "rust inhibitor" is this a better solution to the car wax option which I was also considering? Any help is GREATLY appreciated!

Jen rubin- newburgh, New York

June 1, 2016

Q. I am cleaning what I thought was a brass ceiling light fixture. it only looked "tarnished" in a few spots, so I put it in the all purpose vinegar soak I use for brass cleaning. well, this beautiful fixture that started life about one hundred forty yrs ago as a hanging oil lamp has certainly thrown me for a loop. It was either brass or gold plated and all copper underneath. Now I have a beautiful fixture that will turn ugly brown, then green if I don't clear coat it. It's going to be electrified and hanging ten feet above the floor, so, it isn't something that can be taken down every other year for cleaning. Please advise as to what to coat the copper in. Thanks, --ruth

ruth miller- ellettsville indiana usa

October 14, 2016

Q. I'm trying to make copper electrical connections using copper sheeting and while I'd like to stop the copper from corroding, I also don't want to reduce the conductivity, is there a simple way to do this? I've seen people will tin the copper but it's more of a process than I really want to do. So far it's seeming the best though.

John francis murphy- san francisco California usa

December 12, 2017

A. Hi John. Unfortunately, "don't want to reduce the conductivity" may not be quite explicit enough. Hard gold plating is the ultimate in not reducing the conductivity, with other platings like tin, silver, and nickel being possible and offering intermediate conductivity, but merely wiping or dipping into a solution of sodium benzotriazole based copper preservative may be sufficient. Best of luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

January 2018

A. I cannot offer comment or endorsement on the product never having tried it, but based on some of the things I have read it may solve some of the problems some people are having IF it delivers as advertised. The stuff is called Everbrite [a finishing.com supporting advertiser].

Jesse Tetrault- Victoria, BC, Canada

January 8, 2018

Q. I have been wanting to sell copper hand stamped bracelets as a hobby and want to ask few question about oxidization. My city has high humid levels and the copper blackens within 36 hrs. I want to keep its shine/finish last long. How can this be achieved? I did buffing of the bracelet ...although it gives beautiful shine the result is only temporary and oxidizes soon (also my finger prints get imprinted on it). Somewhere I read that polishing + lacquer it with copper - will give the desired result. I am not sure as I read terms like plating / sealant spray / anti tarnish / lacquer are they all the same or different techniques? Would appreciate if any of you help me with this. Thanks !

John Frezo- Mumbai, India

March 16, 2018

A. Hi John. You can apply any brass lacquer to your bracelets; an advantage to brass lacquer is that it is easily removable with lacquer thinner ⇦ this on eBay or Amazon [affil links] Warning! flammable! for re-application later, and easily thinned with lacquer thinner ⇦ this on eBay or Amazon [affil links] Warning! flammable! so 3 or 4 light coats can be used. Or you can try Incralac ⇦ this on eBay or Amazon [affil links] , which is brass lacquer but with benzotriazole in it to discourage tarnish under the lacquer.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

April 2018

Q. Hello Ted. I am based in a third world country and there is barely any solution available for sealant spray etc. I have read that clear nail polish also works as a sealant. Have you tried it?

Thank You

- Mumbai, India

April 5, 2018

A. Hi John. Yes, India is 3rd world in some of its areas, but first world in other places. Somewhere in your fascinating country every product is surely available :-)

I do not deal in bracelets & such, so I have no experience in using nail polish on copper jewelry. But it is an acrylic lacquer, and I believe you can thin it withacetone ⇦ this on eBay or Amazon [affil links] Warning! highly Flammable! ... so to some degree I think it will function fine as a brass lacquer, although treating first with sodium benzotriazole is always a good idea.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

April 2018

from www.nunndesign.com/how-to-clean-copper-and-prevent-copper-from-tarnishing-again/

A Kova

Earthling - Adelaide, Australia

March 19, 2022

Q, A, or Comment on THIS thread -or- Start a NEW Thread