Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

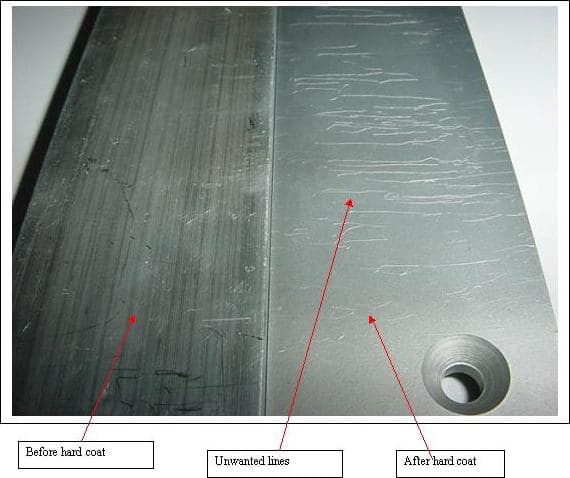

Unexpected lines in finish after hard coating

Q. I am design engineer current working on an extrusion product which is using AL6063 with hard coating.

The problem is after hard coating on the AL6063 extrusion, a lot of lines appear on the surface of part. I need help from anodizing expert on troubleshooting the root cause.

Thanks in advance

Gary Chan- Georgetown, Penang, Malaysia

2004

A. That seems to be a common occurrence with that particular extruded alloy. I'm not a metallurgist, but have been an anodizer for 17 years. I don't work with that particular alloy anymore, so I really haven't spent any time trying to troubleshoot the problem you are seeing...there may not be much the anodizer can do. I would try changing material, if possible. Perhaps a coater (in this forum) with more experience with that alloy may be able to help.

Marc Green

anodizer - Boise, Idaho

2004

A. What is the shape of the parts? Cracking on external curves or cracking on internal curves?

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

2004

2004

![]() My bad, Robert. I was late in getting Mr. Chan's graphic posted, but here it is:

My bad, Robert. I was late in getting Mr. Chan's graphic posted, but here it is:

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Stress corrosion cracking (SCC) is caused by simultaneous static tension and corrosion. SCC will only occur if three conditions are fulfilled at the same time, these are;

The alloy must be sensitive to SCC, the environment must be aggressive and the tension applied to the structure must be sufficient.

SCC is normally not a problem in the AlMgSi-alloys unless the quenching rate has been to slow, but even then only under high transverse stress. AlMg alloys with more than 4% Mg and high strength alloys from the 2000- or 7000-groups can experience SCC at certain conditions.

Michael Balda- Prophetstown, Illinois, USA

2004

A. 6063 ALLOY WILL SHOW THE CRACKS WHICH USUALLY OCCUR IN GRAIN BOUNDARIES. IT RELATES TO THE PROPER HEAT TREATMENT OF THE ALLOY. MANY EXTRUDERS TRY TO EXTRUDE THE METAL AND ACHIEVE A COOL DOWN RATE SUFFICIENTLY FAST TO SERVE AS THE SOLUTION HEAT TREATMENT OF THE EXTRUSION. WHEN THE RATE OF COOLING IS TOO SLOW AND ALLOWS THE GROUND BOUNDARY PRECIPITATION TO OCCUR IT ADVERSELY AFFECTS ANODIZING, RESULTING IN CRACKS. VERIFY THE HARDNESS OF THE MATERIAL AND IT WILL BE A FEW POINTS LOWER IN HARDNESS.

BILL BASSETT- BRANDON, Mississippi, USA

2004

Q. I am having parts anodized per type III hardcoat. All of the part are coming back with vertical lines running up the part. This is an issue as there is a critical cross hatch callout that involves a certain surface finish. Does any one know why these are showing up on these parts? Parts are racked vertically and there is no pattern in where they are showing up in relation to where they are racked.

Buyer - Grand Junction, Colorado, USA

November 5, 2013

A. Andy

The linear lines look like the natural grain of the material showing in the anodize. The thicker the coating and higher the current density, the more pronounced it will be. If not kept to a minimum, the pre-treatment etch can bring the grain out as well.

- Colorado Springs, Colorado

November 7, 2013

Q, A, or Comment on THIS thread -or- Start a NEW Thread