Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

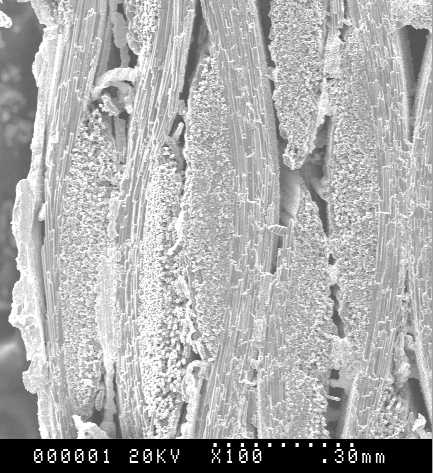

Copper Plating Of Unequally Porous Material

Q. I have an unequally porous material. The apparent porosity of the material is about 15-20% and the diameter of the hole is from 3 to 100 micron. May I use periodic pulse reverse (PPR) to introduce copper into the pore? Is there any better method with which I can achieve the aim? The third question is how can I get the details of the references, especially 3 and 5, in the article "A Review Of Copper Plating High Aspect Ratio Plated Through Hole Papers".

Thank you.

Changqingtongstudent - Xian, Shanxi, China

2004

Q. Thanks for your reply. The details are as follow: I have a kind of electric unequal porous material. The open porosity of the material is about 15-20% and the diameter of the hole is from 3 to 100 micron. I want to infiltrate copper into the pore by periodic pulse reverse (PPR). The only thing I have an interest in is the quantity of infiltrated copper rather than the surface condition. I wonder whether this method is feasible. Is there any better method with which I can achieve the aim? The third question is how I can get the details of the references, especially 3 and 5, in your article "A Review Of Copper Plating High Aspect Ratio Plated Through Hole Papers".

Thank you.

Changqintongstudent - Xian, Shanxi, China

2004

A. PC FAB magazine is now part of PRINTED CIRCUIT DESIGN & MANUFACTURE, published by UP MEDIA GROUP in Atlanta, Georgia, USA.

Tom Gallant- Long Beach, California, USA

2004

Q, A, or Comment on THIS thread -or- Start a NEW Thread