Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

How to clean/brighten 'anodized' aluminum

Q. Hi,

I have an old PD4104 GMC bus that I am restoring. I want to polish its exterior aluminum siding. Have bought many polishers without any success. Someone suggested that the aluminum sidings were 'anodized' when manufactured, and that making it shining its nearly impossible without damaging the metal. Anyone out there with any suggestions/assistance in this matter will be greatly appreciated.

Hobbyist - Norwalk, California, U.S.

2004

A. It probably is protected by an anodized or clearcoat. Bare aluminum corrodes quickly so it needs a protective coating. If you do polish the material it will remove any protective coating that may be there and it will corrode pretty soon if you don't have it recoated.

Jason Aube- Flint, Michigan

2004

Q. I was wondering if you have found a way to polish. My bus has some acid burns and I am trying to remove them.

Sean Torres- Lafayette, Colorado

2004

A. Sean - if it is anodized then I bet you'll battle to polish it/clean it/whatever. Anodizing if done OK is very hard and even light abrasion won't affect the surface. But, if there is some other coating on it like a clearcoat, I suggest you use waterpaper and sand out the acid marks deep as you need to then use a high speed drill with a cloth mop and some polishing compound (rouge). Once you have the required finish, just apply a clearcoat over. If you really wanted to and it was in your budget just have it stripped of any existing anodizing if that is what's there and get it replated, but remember that if the anodizing shop does a strong etch you will loose any shiny finish you have spent time on - just find a good balance. my $0.02

Michael GeorgiadisRDI - Kzn, South Africa

2004

A. oven cleaner

⇦ this on

eBay or

Amazon [affil links] will remove the anodized coating. But it's very caustic, nasty stuff very capable of blinding you, burning you, or leaving you with aching lungs. And you would be using it for a purpose for which it was not intended, which makes it all the more dangerous and more demanding of the proper personnel protective equipment. Oven cleaner also attacks the aluminum, so you need to leave it on only for the right length of time. Then you need to buff and clearcoat. As Michael implies, if it's worth doing it's probably worth sending to an anodizing shop.

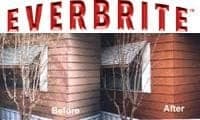

One thing that might be worth a try instead is Everbrite [a finishing.com supporting advertiser]. The general guideline is that if it doesn't look good when wet, this won't help. But if it looks good wet (due to the leveling effect of the water), Everbrite can make it look pretty much like that.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Re-polishing aluminum after anodizing

Q. We have an anodizing company and produce anodizing aluminium profiles. And I am a chemist in this company.

I want to learn something about polishing processes or increasing gloss of aluminium profiles both of matte and bright surface.

After finishing the anodizing process, we want the begin polishing (re polishing) again, like:

press - mechanical polishing - anodizing - re-polishing

Are there any polishing products (or something like that) for polishing after anodizing -- not only matte surfaces but also bright surfaces?

Or, are there any applications for increasing gloss of aluminium at the final step?

chemistry - TURKEY, ISTANBUL

March 2, 2015

A. I didn't hear about re-polishing after anodizing. Also I don't suppose an application like that because when you anodize a profile, the sealing layer will be to protect it from exterior effects. So if you even polish it, you will never succeed. If you improve brightness, check your alloy (for example high Fe rate means less brightness, +6463 series suitable for brightness). Brightness not only related alloy, also anodizing process (hot sealing makes it more dull compared to cold sealing. Plus, anodizing bath's aluminium rate should be 5-15 gr/lt. If you use electrolytic polishing bath, it gives more extra brightness, etc.)

sincerely,

- sakarya,turkey

March 2, 2015

|

A. Busra - Colorado Springs, Colorado March 3, 2015 Q. I saw re-polishing of profile once, nearly 1-2 years ago. It seemed like lacquer appearance (may be clearcoat effect). And so much brighter than polished surface that we do. And also you can use on the matte surface. Then it seems like lacquer appearance as I said. chemistry - TURKEY, ISTANBUL March 4, 2015 |

A. Hi. Everbrite is a clearcoat that is used to offer some corrosion protection to metal surfaces. I am not aware of it being used on anodized aluminum by OEMS to brighten it. Rather, it is sometimes used on old anodized or painted aluminum to level the surface and give a "wet look" and reduce the chaulky look of old aluminum. You are certainly welcome to contact Everbrite and see if it has any applicability to your situation, but I think Willie's suggestion is closer to the mark. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

March 2015

Q, A, or Comment on THIS thread -or- Start a NEW Thread