Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Bonding/soldering galvanized sheet metal

Quickstart: Welding galvanized metal is not recommended because of contamination of the weld and the safety issue of breathing the zinc-rich fumes -- removing the zinc with acid first is discussed. Soldering is possible but it also has issues which are considered. Epoxy may be the easiest answer for some situations. For important joints, mechanical locking or riveting is recommended before any other joining technique

Soldering

Q. Hello

I would like to know if it is possible or practical to solder galvanized sheetmetal on a small roof.

Thank You,

Contractor - Oakland, California, USA

2003

A. To solder galvanize: degrease the area to be soldered, use an acid soldering flux

⇦ this on

eBay

or

Amazon [affil links] , you will probably need some mechanical abrasion WHILE soldering to get the solder to adhere. Historically, the abrasion was supplied by the old-fashioned soldering bolts

⇦ this on

eBay], which were a block of copper on a steel rod with a wood handle . Stick the copper in a fire to heat it up and then use a scrubbing motion on the work after the solder melts. These days we would use a propane torch with a soldering tip.

When you're done, be sure to clean off all the acid flux with a stiff bristle brush and plenty of water. The stuff absorbs moisture from the air and continues being an acid.

- Long Beach, California

2004

A. Yes you can solder galvanized steel much as you do with other metals. The trick is to use muriatic acid ⇦ this on eBay or Amazon [affil links] full strength from the container like what bricklayers use to clean masonry.

Hunt MillerApril 22, 2008

- Beallsville, Maryland, USA

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I would like to either solder, or wire-weld, two pieces of 18 ga. galvanized sheet metal together. Any recommendations as to which procedure, if either, would produce the best looking, and strongest, results? Also, what equipment will I need?

Thank you!

hobbyist (DIY) - Grand Rapids, Michigan

2004

Welding

A. Soldering is probably your best bet from a safety standpoint. Many years ago in a beginners welding course, we were told "Don't weld zinc or galvanize. The fumes are 'Not compatible with life and destroy lung tissue on contact."

Tom Gallant- Long Beach, California

2004

Ed. note: You can search the site with terms like "welding galvanized metal" to see a dozen long threads about the safety issues of welding galvanizing or otherwise heating it beyond its vaporization temperature.

A. The earlier answer claims that welding galvanized steel destroys lung tissue. Not true.

The result of welding galvanized steel is zinc oxide, which is non-toxic and non carcinogenic.

Yes, breathing the fumes will make you sick, but the effect is temporary. It does not destroy lung tissue.

See this link:

www.sperkoengineering.com/html/articles/WeldingGalvanized.pdf

- Albuquerque, New Mexico

2006

Q. Hello everybody

I have to weld 2 GI sheets both of .5 mm thickness (formerly I used to remove zinc from the portion where I want to weld but the problem is it very time consuming and costly) .

The quantity per day to weld is 5000 pcs.

Thank you and hoping to get some good solution.

Devang

G.I. ring manufacturing - Mumbai, India

September 1, 2013

Q. How to weld precoated galvanized sheet? Thickness is 0.6 mm to 1.00 mm.

AKASH ARORA- jaipur , rajasthan , India

October 19, 2015

A. Welding galvanized steel, in my limited experience, is not really ideal. Noxious/poisonous gasses can/are emitted and some type of wispy ash deposits are left around/on the weldment, and presumably, in the weldment.

What I found, searching online, is that using muriatic acid (hydrochloric acid, by another name, if I am correct) will remove the galvanizing from where I need to weld and allow a good weldment. Then I re-coat with a cold galvanizing spray if the part requires it.

Just my little experience.

--HC

- Decatur, Texas, USA

October 20, 2015

A. Having been a welder in a fab shop for more years than I'm willing to admit, we regularly welded galvanized material, and about half of that time was spent inside the vessels/tanks we built with no ventilation or respirators.

Somewhere along the way we heard what we believed to be an old wives tale that if you drank a little milk all day it would keep you from becoming sick.

One day we tried it and from then on we kept milk in the soda machine every time we had to weld galvanize.

You can believe this or not, but all eight full-time welders believe and many of the temps that passed through.

- Rapid City, South Dakota

October 14, 2016

A. We call it zinc fever ... flu-like symptoms after some fool has put a galvanised item into a gas forge for example. Drink a pint of whole milk and the symptoms go in about an hour -- I believe it acts as a 'chelating' agent and binds the zinc,

Mark White- London UK

November 7, 2020

Epoxy or Liquid Nails, plus locking or riveting

Q. I'm trying to join 26 gauge galvanized to 26 gauge galvanized, with a 1 1/2"-wide lap joint. It is for roof flashing. I'm worried about acid residue remaining in the hidden lap area.

Can I use epoxy to join the two pieces, instead of solder? Will the epoxy be as strong as solder?

- Monroe, Louisiana

2004

A. I've always been impressed with JB Weld

⇦ this on

eBay or

Amazon [affil links]

, George, and I think it will work fine on such lap joints. But make sure the metal is clean, and I'd suggest lightly sanding the joint area just moments before epoxying. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Soldering

A. When soldering galvanized sheet metal, always use a non-corrosive flux such as ruby fluid.

If none is available, use 'cut' muriatic (hydrochloric) acid. Do this by pouring the acid into a glass container and adding zinc (roofing nails and or slivers of galvanized metal) until it no longer bubbles.Strain the resulting liquid into another glass container. However, I might question the use of 26 ga. metal for a roofing application, for most uses it is much too thin to last for any acceptable length of time, while 24 ga. is much thicker and will be much more durable. Also, to make a strong joint the metal should be 'locked' together or at the very least riveted no further apart than 3 inches.

- Agency, Missouri

2006

! As to the use of 26 ga. or 24 ga. galvanized sheet materials in roof flashing applications, it is not the thickness of the metals that promotes or degrades the longevity of the flashing, but the weight of the galvanized coating and the applications to which the metals are applied.

The thickness, or gauge, of sheet metals in conventional roof flashing applications contributes to their span strength and performance under thermal stresses, but not to its corrosion resistance, per se. It is the amount and nature of the galvanized coating which affords the metal its primary corrosion resistance.

In short, 26 ga. G-90 galvanized sheet metals are suitable, and often preferable because of their workability, for roof flashing applications in most cases where span is limited. There is no appreciable increased corrosion resistance for G-90 galvanized coatings on thicker metals.

- Raleigh, North Carolina

2007

A. JB Weld is costly for a large project, though if money is of no importance, go for it.

I would try Liquid Nails for Roofs

⇦ this on

eBay or

Amazon [affil links]

for the roofing job mentioned earlier.

As for adding zinc to HCl to "cut" it until it no longer bubbles, I have no idea why anyone would do such a thing. You are essentially making a caustic material from still a caustic material to begin with; that contradicts the premise of using something that is not caustic. Dilute ZnCl2 is still caustic. Common flux is a ZnCl2 paste so why not just dilute the paste if that is the end result?

Checking or the use of a wire wheel may also be useful.

Tom Blank- Grants Pass, Oregon, USA

November 6, 2011

Q. What is the best way for joining galvanized sheet metal?

Abbas GeramiResearcher - Alhambra, California

January 9, 2009

A. Hi, Abbas. Five ways were mentioned so far: welding, soldering, epoxying, mechanical locking, and riveting (and combinations). Each has advantages & disadvantages; if one was always better, people wouldn't do the others :-)

If you can give us some info about your particular situation, the readers should be able to advise which they think is best for your case. Thanks!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Soldering

Q. Hi, I'm trying to do similar thing, galvanized flashing. I experimented with solder and torch ... I'm doing something wrong because after 4 hours of messing around I was unable to join 2 pieces of sheet metal together! Help !

Egert Oja- Los Angeles , California

February 24, 2010

Hi, Egert. You say you were using solder and torch, whereas some posters say that you must use a solder bolt (copper head soldering iron) because mechanical abrasion is mandatory. I can't swear that they are right, but I do remember my father (a plumber/roofer) always using a solder bolt rather than a torch many decades ago. Thanks.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

February 2010

Soldering

![]() All good information when pieced together. Here is some more and a question.

All good information when pieced together. Here is some more and a question.

Q. Last night I was trying to repair a leaking fitting at the bottom of a 100 gallon galvanized barrel that had been fitted with black iron pipe fittings: 1 inch male to 3/4 female flanged reducer which was further mechanically reduced to 1/8 inch female pipe. This was a common set up around here for gravity fed fuel oil heaters. These tanks are useful for storing used motor oil, solvent, asphalt crack-filler/sealer products, etc. Imagine the oil, grease, dirt and corrosion in and around the old joint. Mechanical and fluid (liquid and air) cleaning worked well except in the non accessible recesses. I used a lot of flux with a brush but the bristles melted and contaminated the area. I was using a torch and not a heavy iron. I was having a problem getting the parts to tin (to accept the solder) until I scrubbed them with the flux brush (yes, with its melted bristles). I brushed the debris from the top of the melted solder pool and scrubbed underneath. I pushed the solder around with the flame. I eventually got it all to stick or I should say flow out in a cohesive manner. You don't want adhesion type "sticking" That is a cold joint that doesn't "bond the two metals together with a metal that melts at a lower temp". Brazing is another method of soldering by definition. I always found brazing easier.

What I (re)learned from my youth that I had forgot was the absolute need for cleanliness, the abrasion and/or flux or both, the proper amount of heat (and don't torch your brush) and the removal of all corrosion immediately before the repair.

It brought back memories of an old mechanic in the 70s (he was 80 then) who showed me how to repair a gas tank with a copper patch by soldering it on the tank with a heavy iron heated by a blow torch. No flame near the tank, only the hot iron.

Q. Now the question: I don't remember whether he first tinned the lapped sides and then put the copper on the metal tank and heated them to join them (obviously adding more solder), or whether he merely cleaned and brazed them well first, laid the copper on the metal and then heated and flowed the solder between them. What technique would you guys use?

- Susanville, California

July 7, 2010

Q. Some of the joints of one of my metal radiator covers have come apart. They appear to have been soldered originally. I assume that the metal is galvanized steel, but am not sure. I am a professional silversmith, but have no experience with this kind of soldering. The two spots to be soldered are within an inch and a quarter of a painted part of the cover. Can I solder these without harming the painted surface with a soldering iron? What kind would I use? What solder? What flux? If I can't do this safely myself, what kind of person would I look for to do this repair?

Jan StigbergDIY homeowner - Belmont, Massachusetts, USA

February 1, 2012

Epoxy

A. Hi, Jan.

Nobody can assure you that the heat of soldering will not harm an unknown old art paint. Epoxy sounds more practical to me.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Soldering

A. Soldering Galvanized sheet metal ... I own a rain gutter company and we routinely (and easily) solder our half round galvanized gutter. However some galvanized sheet metal is impossible to solder. I think it depends on the alloys used in the galvanizing. Beware look alike products like Zap or Zincalume, these cannot be soldered either. I recently learned the hard way to obtain a sample of the metal and try soldering before fabricating.

Scott Wuebber- Bozeman, Montana

March 26, 2012

Q. What to use to seal a galvanized fishing boat live well? 3 0f 4 edges are open on the bottom of the live well. poorly designed.

I have used JB weld and a few others over the years buy they all let loose after a year or two I believe with temperature changes, etc.

I tried low heat welding once but it started to burn the carpet on the outside of tank.

frustrated.

- Hortonville Wisconsin usa

March 24, 2020

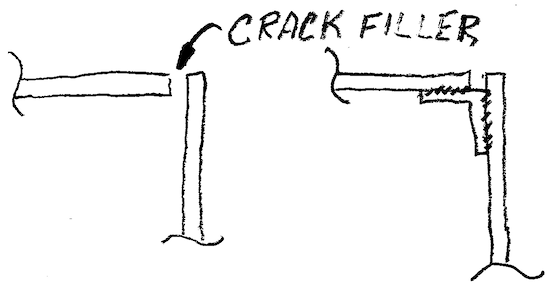

Epoxy

A. Hi Jeff. If the epoxy is being used as a crack filler, yes a crack filler is going to give out pretty quickly.

But if you can make little angle irons out of sheet metal and epoxy them in place I think the repair will last.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q, A, or Comment on THIS thread -or- Start a NEW Thread