Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Painting marine compasses and boat/ship bronze & brass

MARINE COMPASSES

All About Marine Compasses and Their Adjustment

by A. Pickles (1990)

avail from Amazon

Finding the Error of the Marine Compass on Board Ship

by Benjamin Franklin Greene (1875 -- in public domain)

avail from AbeBooks or eBay or Amazon

The Marine Compass: (paper presented to United States Naval Institute at Annapolis

by Benjamin Franklin Greene (1874)

avail from AbeBooks or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

Q. I do marine compass repair. Many marine compasses have a bronze "top ring" which seals the oil chamber. Frequently the top rings are tarnished or chipped --> they need repainting with a gloss black enamel. I've had much trouble getting a paint/primer to bond tightly to the bronze.

Things tried:

1) Krylon with and without primer

2) Hardhat with and without primer

3) Etching the clean bronze with ferric chloride

4) High % zinc primer

In all cases the problem occurs in the countersunk screw holes when the SS mach screws are torqued to proper ft-lbs. The paint tears away from the holes and surrounding surface. Much frustration! Here's hoping for some wisdom.

Note: I am NOT painting a bronze color - rather I need to paint black ONTO bronze.

Thanks in advance.

Robert S.Petersoncompass repair - Elgin, Illinois

2004

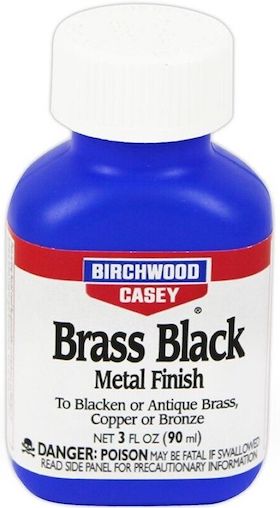

A. Try an oxide solution. Birchwood Casey Company has a Black gel that you paint on with a brush [Brass Black on eBay or Amazon [affil links] . It turns the compass black with a process such as gun bluing. You need to rough the surface up a bit with a sand blaster or sandpaper to allow the oxide to bite.

Rich Darby- Danville, Illinois

2005

A. I also repair compasses. That material is usually not bronze but naval brass (High zinc content). We continue to use Krylon with a primer. The key seems to be curing time. We do not get the problem if we allow a 24-hour cure before inserting fasteners. I have also used a dab of petrolatum in the holes on some jobs.

Bill Haimes- Everett, Washington

July 16, 2009

Q. I'm not a professional finisher, but I do have a big boat with lots of bronze and I hate verdigris so it's a curse.

When polished I want bronze to stay polished and when painted I want it to stay painted - neither of which is easy.

First thing, nothing will stick to bronze tarnish - it has to be removed and I think preferably to at least a low polish state.

I don't believe any primers (etch or otherwise) will help, your finish coating has to go directly onto the metal.

For a black coating to handle mechanical stress, I think your choices boil down to: epoxy paint, powder coating, or electroplating with black chrome.

For a clear finish "Wattyl Paints" supply an aerosol spray specifically for copper that works on Bronze - (5 years in full sun before it starts to tarnish under the coating) - being a very hard coating, it may work as a primer under black paint - But I'd still use epoxy.

Thought of polishing the Bronze ring? very nautical look and the tarnishing problem will be tomorrow's problem for somebody else.

good luck

- Brisbane Australia

June 7, 2009

Q, A, or Comment on THIS thread -or- Start a NEW Thread