Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

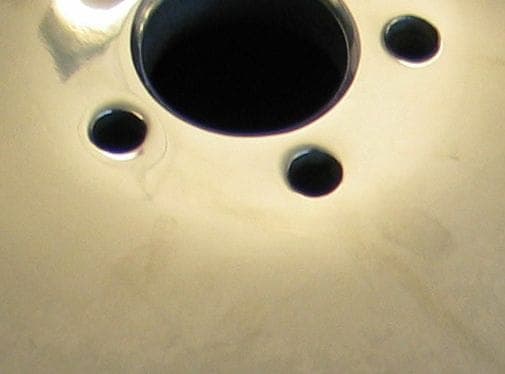

Mirror polishing of die casted aluminum

We have a big aluminum disc made by pressure die casting. The disc is sold as the base for chairs. We are interested in making a version where the surface is mirror polished (shiny). But when we try on the existing disc surface it is very difficult to get a satisfactory surface look. It seem like the flow pattern is getting visible.

The material we use to day is ADC 12, but we wonder if this is the correct material to use with our new requirements.

Does anyone have experience with mirror polishing of die casted aluminium that can give any recommendation of what to do?

mechanical engineer - Randers, Denmark

2004

You did not mention it but you should use grease added to the abrasive wheel. Keep in mind that aluminum has a very low melting temp. If excessive force or speed is applied the surface can get VERY HOT. Metal flow is an indication of temperature close to the melting point.

Guillermo MarrufoMonterrey, NL, Mexico

2004

We have seen in one of the factories in S.Korea where they were using a buffing wheel for polishing ADC 6 two wheeler Lever. They said that the wheel was imported from Ghana or some other African country and it was made of Hemp or some sort of grass. We were amazed at the type of finish achieved.Pl think and try in that way It is a very cheap and best solution.

Prabhu Ram- India

2004

Q, A, or Comment on THIS thread -or- Start a NEW Thread