Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Clear coat for copper protection

Q. I have failed to find a lasting spray on lacquer or clearcoat for copper copulas exposed to extreme climates.The patina usually starts at the seams where the most expansion and contraction occurs.Mirror finished with rouge,washed lightly with acid to etch then sprayed.whats wrong? High volume, exotic process not cost effective. Any info please? Thank you

Richard Travesrestoration - Searsport Maine USA

2000

A. Dear Richard,

Your final acid rinse may be leaving acid residue in the seams. Some acids have an affinity for water and may be causing premature coating failure. Many metal maintenance companies do the final rinse with solvent to remove the polishing compound. Pay extra attention to the seams, making sure they are clean to bare metal. If you use a clear coating designed for brass or copper, you should not need to acid etch to get proper adhesion. A one part exterior brass lacquer should give two to four years of protection. If you topcoat that with an exterior urethane lacquer, you should expect another one to three years of service.

adv.

Our company manufactures these coatings, please contact us if you would like specific recommendations.

G. J. Nikolas & Co., Inc.

Bellwood, Illinois

2000

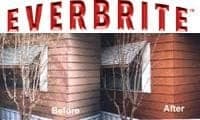

adv.

Everbrite Protective Coating is a one part, user friendly clear coat that will protect plated and painted metals from tarnishing, corrosion and oxidation. It remains flexible and will expand and contract with the substrate with temperature changes. The finish will last for years and can be maintained indefinitely by recoating without any need for stripping the original coat. It will not build up as it is self annealing. It is also very economical. Please feel free to contact us if we can help.

Everbrite Coatings

Rancho Cordova, California

2000

A. Dear Richard, The most ideal solution to your problem is a clear coat of electrophoretic lacquer (Cathodic).

Varun Bhalla- Delhi, India

2000

Protecting Copper Gutters

Q. Dear Sir:

What clear coat product would you recommend for protection copper gutters from tarnishing?

- Detroit, Michigan

2001

A. Hello Samuel,

Since this is a non-commercial forum, I can't come out and tell you who has the best lacquer in the world. The best recommendations I could give you are to focus on the preparatory work and application methods. If you are polishing the copper, all of the compound needs to be removed. If it's brand new, there might be some kind of protective coating on the gutters, manufacturers will coat tarnishable metals with something so they don't look ugly when you go to buy the finished product. That needs to come off, you can usually take compound and prior coatings off with lacquer thinner

⇦ this on

eBay

or

Amazon

[affil links] Warning! flammable!

. Next is application. If you want to get it over with and don't mind wasting your coating due to overspray, get some aerosol cans at the hardware store. Otherwise get a HVLP gun

⇦ this on

eBay or

Amazon [affil links]

or somebody with one, an air compressor

[adv: air compressors on

eBay

or

Amazon [affil links] and a liquid coating.

Best of luck,

G. J. Nikolas &Co.,Inc.

Bellwood, Illinois

2001

Exterior high gloss mirror finish clear coat for copper

Q. I'm manufacturing low volume, high end, decorative wall lighting fixture from 16 ounce (24 gauge) raw copper. These fixtures will be for interior and exterior applications. We want to either paint or spray on a clear high gloss topcoat that is almost invisible, non-yellowing, UV and weather resistant, shows no brush strokes, wrinkles, etc. We want the copper to look like raw, beautifully shined copper and hold up in harsh environments. We would also like a one-component process (no mixing of epoxies, etc), but will look at other systems if we must. Thanks for any help out there.

Charles Laughon- Wilmington, North Carolina

2003

A. I don't think there is a vacuum deposited hard coating that will be the right color, so I think clear electrophoretic lacquer will be the most durable topcoat you can apply. But if it must be field applied, two-component automotive clearcoat is a good choice.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2003

Protecting outdoor copper water features / bird baths

Q. I am looking for a clear coat finish for an outdoor copper water feature that will protect from tarnish. I am hoping to find something easy to apply and non-toxic.

Robin CarpenterHome Owner - Delta, Ohio, U.S.A.

2004

Q. I am looking for a non toxic protective coating to apply to an outdoor copper birdbath to shield it from the elements and preserve the copper finish. What product/s do you recommend?

Laura WhitneyHomeowner - Encinitas

January 22, 2009

A. Hi, folks. brass lacquer

⇦ this on

eBay

or

Amazon [affil links]

would be the most standard approach to protecting copper and brass, and offers simple removal for periodic re-do's. Some of the lacquers like Incralac

⇦ this on

eBay or

Amazon [affil links]

or Permalac [adv: Permalac on

eBay] have benzotriazole

⇦ this on

eBay

or

Amazon [affil links]

or other copper preservatives incorporated in them, and are probably best. Other threads on this site that go into more detail on copper & brass preservation include topics

61, 22161, and 24167. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

January 28, 2009

Heat resistant clear coat needed for my copper plated stove

Q. I recently purchased a 1953 copper plated Chambers range. It had a clear coat (I am told it was ceramic) over the plating which is in a few places breaking down allowing the copper to tarnish. Some places are showing steel too - from enthusiastic scrubbing over the last 53 years.

I have found a local company who will replate it for me, but the auto paint shop they normally do business with wants nothing to do with my clear coat request... This stove was famous for it's insulation - actually holding temp for hours after preheating so I don't think the oven door is a huge issue, but the little back splash will probably see hot grease in use.

I really appreciate the help!

Phoebe Gibbs

hobbyist - Asheville, North Carolina

2006

A. Try a Powdercoating shop and see if they have a clear powdercoat that will work.

Rod Walters- Des Moines, Iowa

2006

Q. I'm looking to copper plate some engine parts like valve covers. I'm concerned about fingerprints, tarnish, and patina. What high temperature clear coating can be applied that will give years of protection to the parts? It must be able to withstand high underhood temps.

Also, can I copper plate aluminum?

Finally, would anodizing be better for my application?

hobbyist - St. Petersburg, Florida, USA

2006

A. I am not confident that there is any treatment for copper that will prevent oxidation at high temperatures, but valve covers are not as hot as exhaust manifolds, so it may be possible. Yes, aluminum can be copper plated, or it can be anodized and dyed a copper-ish color.

In any case, maintaining a bright copper color at heat may be a problem. If you don't like the look of chrome plating, maybe gold would be an alternative.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2006

Clearcoating a copper shower to protect the blues and greens

Q. I am renovating my first house, and I am doing everything different from the norm. I want to build a shower stall with copper walls. I want to burn the copper first with a torch to create the blues and greens you see with burnt copper. What kind of clear coat sealer should I use to keep the walls from tarnishing?

Thank you.

artist - Westport, Kentucky, USA

2007

A. Hi Nicholas. You can try brass lacquer ⇦ this on eBay or Amazon [affil links] or a clear coating like Everbrite [a finishing.com supporting advertiser] from the site's supporting sponsor, or a two-component automotive clearcoat. But maintaining the more subtle colors may prove impossible with any clearcoat: see letter 2662 to understand why. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

Need very durable clearcoat for copper & brass sinks and bathtubs

Q. We are one of the Metals Finisher in Bali, having some nature problems protecting the Copper and Brass materials made items such as Bathtub, Lavatories and such a kind those are in direct contact to water either cool or warm.

Since the works is an art to be in function, our customers occasionally request for a Bright Polished Shinny Copper or Brass but often dipped to blackening liquid of black brass to obtain Bronze antique color for brass or reddish antique color for copper. The top Coat of a Solvent Resin based Clear Coat so far could not afford enough to protect further oxidation and came shortly to peeling off after two months since the items is in function and had a direct contact to water, detergent etc.

My question are ; Since the set finishing is a bright-shinny copper or brass set out by the customer, how can we manage and what to apply appropriately to solve out those situation to offer the solution to last the Top Coat of a Clear or Matte Finished color where we are keen to have the long-last minimum of 5 years?

Your kind favor of a comprehensive brief and guidelines is highly appreciated.

Thank you and regards, Paul.

- Bangli, Bali - Indonesia.

January 3, 2015

A. Paul,

Perhaps a clear acrylic sealer would work for top coat.

Blake Kneedler

Feather Hollow Eng. - Stockton, California

February 3, 2015

Keeping desired finish in copper kitchen sink

Q. Hello from Colorado. I have a large double bowl farmhouse copper sink. The apron has a beautiful patina. However, the inside is dreadful looking! It will quickly patina, but every object, every liquid or scrap, anything put in the sink leaves it's mark. It always has drip marks down all sides and the bottom has spots and rings from items placed in it. It reacts to absolutely everything! How do I keep it bright copper, or keep it brown patina, either one? At this point I don't care wbich! My copper bathroom sinks don't have the same issues because of the type of use. How do you get the look and keep it in a constantly used sink?

Thank you in advance.

homemaker - Kersey, Colorado, usa

March 3, 2015

Hi Jo. We appended your inquiry to a long thread on the subject, which should offer food for thought. Considering the water (which limits the use of lacquers) and the mechanical banging around (which will scuff just about any clearcoat), the most promising approach just might be automotive 2-component clearcoat. Because this hardens as a result of chemical reaction rather than drying, it is harder -- and hopefully less scuff-prone -- than most clear coats. Another possibility, although short-lived, would be waxing. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

February 2015

Lacquering of copper with airbrush

Q. My situation:I'm trying to lacquer a copper mirror which I have polished with Tripoli and polinum for a high shine, the polishing is finished and I am extremely happy with the quality but when airbrushing on "ercolac" lacquer (which is a commercial lacquer in the watch making and jewellery trade) I am losing a lot of shine (the lacquer seems slightly dull) . I am thinning the lacquer with ercolac thinner to make it flow through the airbrush and have tried adjusting the mixture a little. Is it the brand (I can't believe a jewellery trade lacquer would not be crystal clear) or the method (airbrush) or the mixture? This is really important to me as I need a clear strong lacquer as I'm developing a patina range in silver and I can't be losing clarity

Thanks

RK Jewellery Designs - London

July 21, 2018

Q, A, or Comment on THIS thread -or- Start a NEW Thread