-----

Need a way to clean plating saddles from service catwalk

I am looking for a way to clean saddles on copper, nickel and chrome plating tanks without having to climb over the tops of the tanks. Also, I'm looking for a good way to fish parts out of tanks without getting on top of the tanks.

Howard Nicholsonplating shop - Bowling Green, Kentucky, U.S.A.

2003

Several styles of "self-cleaning" saddles have been used for decades, designed along the lines of knife switches. They are a bit more complicated than simple V-saddles, but may be worth the effort.

Magnets on poles are traditionally used to fish fallen parts out of tanks. It may be more complicated than it's worth, but I have seen fiberglass grates, the dimensions of the tank bottom, kept in place to near the bottom of the tanks, and then raised to remove the fallen parts. The FRP manufacturers offer a wide-spaced light duty grating they use to support the packing material of fume scrubbers; you don't need to use a grating strong enough for walkways.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

2003

Could you give me some direction on which companies sell self cleaning saddles?

Howard Nicholsonplating on plastics - Bowling Green, Kentucky, U.S.A.

2003

Sorry, Howard, I don't know offhand who offers them these days. Perhaps one of our advertisers will respond to you, or you could shop the directory here for plating equipment suppliers. The patents probably ran out a long time ago since I've seen them on 30 year old equipment.

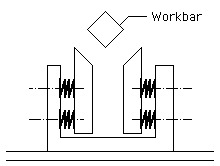

The principal is simply that copper edges are positioned vertically, pushed towards the center of the saddle by springs, and the descending workbar rubs down along these vertical edges. The principal is to scrape away deposits instead of sitting down on top of them. The sketch is similar to one version.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

2003

Q, A, or Comment on THIS thread -or- Start a NEW Thread