-----

Help with solder contamination questions

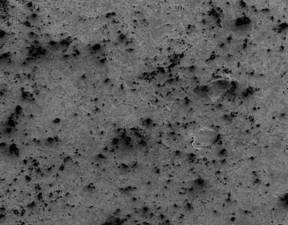

We make a copper double clad 95/5 Pb/sn strip that goes to our customer (a stamper). We roll the product with vanishing oil and use perch. on wiper pads prior to wrapping and shipping. The stamper claims they also use vanishing oil when stamping and then to clean the product, the parts are placed and cleaned in a distilled perch. process. They claim it is constantly purified. The end user has claimed they have sheer test failure and sent photos of "contamination" on the surface of the solder parts and said this was the cause for their failure. We sent our strip out for analysis as well as the stamped parts The photos from the strip came back clean. The lab said our strip had what they considered normal handling issues. Dust and a small amount of embedded silica.The labs photos of the stamped parts show black spots on the surface. Their analysis stated that the stamped parts had carbon, sodium, potassium, chlorine and oxygen.

Can you advise what in the stamping process might put this on the surface and would you consider it to be the cause of the "contamination" that caused the sheet test failure? Thank you for your help in this matter.

The stamper now states that they use a vibratory process to deburr if needed and then the cleaning process is as follows: ultrasonic clean in trichlorethylene.

Denise Salvati- East Setauket, New York

2003

Contamination may be coming from the ultrasonic cleaning operation. The ultrasonic action removes dirt, etc., but if the bath is not changed with sufficient frequency, or if too little surfactant is used, then this might be the source of the contamination.

Toby Padfield- Michigan

2003

Can anyone offer any insight as to what the "proper cleaning" is for an ultrasonic cleaner? Methods, solutions, etc. Also, if they are tumbling these parts with oil on them prior to this cleaning can that be causing the problem?

Denise Salvati- East Setauket, New York

2003

Q, A, or Comment on THIS thread -or- Start a NEW Thread