-----

Formulas for brush plating solutions for gold plating

Q. Dear Sir:

I allow myself to write to request you technical information (recipes) for the preparation of electrochemical solutions (especially those based in Nickel and chromium) for process of Brush Plating specially dedicated to the diameter resizing in axes and holes of steel pieces and other ferrous alloys. This information doesn't exist in my country, for this reason , I request it to you humbly. I have knowledge these solutions are of high concentration and they are quite different to the solutions used in the classic electrochemical processes.

Sincerely,

- Lima, Peru

2002

|

A. Camilo: Monterrey, NL, Mexico

- Lima, Peru |

Q. Is there a simple formula I can follow to make my own gold which I will be using to gold plate emblems on cars electronically? Any help would be appreciated.

Best Regards,

- Dallas, Texas

2003

A. Hi, Frank. It's fairly complicated, and brush plating solutions must be concentrated and probably have thixotropic agents added for thickening.

Even if you know the formulas, it might not make sense anyway. Gold is so expensive that the tack-on costs of the proprietary chemistry are usually a fairly minor mark-up, so I know of no professional platers or jewellers who risk losing very expensive gold to poor plating to try to save a little bit on the carrier chemicals.

The thing in your favor, though, is that car emblems are the easiest thing in all the world to plate -- because all you are doing is taking an item that was polished, pretreated, and beautifully nickel plated to OEM quality, then stripping a few millionths of an inch of chrome from it and replacing that chrome with a few millionths of an inch of gold. Prep is at least 90% of the work in plating, and none is required in the case of gold plating nickel-chrome emblems :-)

Good luck,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

2003

2003

A. Ferrocyanide gold bath (late 19th century):

2,65 gm gold chloride

15 gm potassium ferrocyanide

⇦ on

eBay

or

Amazon [affil link]

15 gm sodium carbonate

⇦ on

eBay or

Amazon]

1 lit water

Stainless steel anode, 2-6 V / 0,5 A/dm2

In boiling water dissolve ferrocyanide; when dissolved, add carbonate; when it is dissolved add gold chloride and boil it a minimum of 30 minutes.

Must be filtered (cold) and then you can use it. Never mix it with acids!

Only grease and oxide free objects can be plated!

- Cerovski vrh Croatia

Q. Greetings:

I was wondering where I might recipes for copper, gold (and silver) non-cyanide electrolytic brush plating baths. I understand several manufacturers market some of these with all sorts of proprietary additives for sale but I am just looking for basic content information for experimental purposes.

Thank you.

chemist - Denver, Colorado, USA

2004

A. Hi J. The Metal Finishing Guidebook or the Electroplating Engineering Handbook ⇦ this on eBay, AbeBooks, or Amazon [affil link] would be good starting sources for 'recipes' for plating solutions. Brush plating solutions are usually more concentrated, closer to a gel, than bath plating solutions -- possibly with barium sulphate or fumed silica as thixotropic agents.

But a quick word of warning for others who may be reading this is that electroplating is about process sequences not recipes. A rule of thumb is that 90% of the effort and plating problems are pretreatment issues. If the substrate is properly prepared, it will usually plate well; if it isn't prepared well, all efforts towards plating it will usually be wasted.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. The only place that I have seen home brew formulas readily available, was several years ago in the Metal Finishing Guidebook. The article was by an engineer at Boeing. Check with Metal Finishing to see if you can get a copy.

James Watts- Navarre, Florida

Q. Thanks for the formula [Goran's ferrocyanide formula] but would you please clarify some values.

2,65 gm gold chloride. Is this 2.65 gms?

Stainless steel anode,2-6 V/o,5 A/dm2.

What is "V/o"?

What is "A/dm2"?

Thanks in advance, Alan.

- NSW, Australia

August 22, 2010

A. Hi, Alan

Europeans sometimes use commas as a decimal point where people from the USA and Australia would expect a period. So, yes, 2,65 is 2.65 and the electrical requirement is 2 to 6 volts at a current density of 0.5 Amps per square decimeter.

Note that this formula involves dangerous cyanides.

Luck and regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Thanks Ted, I thought that was the case. Goran's "recipe", is that for brush or bath plating? I am hoping both. Thanks in advance.

Alan Symbol [returning]- NSW, Australia.

August 25, 2010

A. Hi, Alan.

Goran is a metals conservator at a museum and, as you can see, he is a tremendous resource for historical metal finishing issues. But unless you are trying to replicate something from the 1800's, I personally don't think it makes sense to forego 120 years of progress and use a plating formula from Thomas Edison's early days, probably decades before anyone even thought of brush plating. I suggest, again, purchasing a modern gold plating solution that will deliver a proper deposit, rather than having to spend five or ten times as much applying a plating that needs to be five times as thick in order to deliver a pinhole-free coating :-)

But if you are going to mix up your own chemistry, I hope you are a chemist fully aware of the dangers of cyanide. Professionals never attempt to mix their own gold plating solutions as far as I know; the only people who do so are PhD students when trying to fully understand the influence of complex variables. Best of luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Dear all,

From the advice, I tried to purchase gold solution but it's hard to get from my city. I graduated from chemistry faculty so I'd like to make gold brush plating solution. From letters on this forum, I can make GPC but I don't know exactly the additive agent such as: brightener, hardener ... Please help me if you can. One more question, I wonder why the gold solution I saw on the internet is pink instead of yellow color of GPC. I guess it include mono dispersion of nano gold particles, is it true?

Thank you in advance,

Nice regards,

Anh Nguyen The

- Hanoi, Vietnam

May 8, 2012

A. Hi, Anh.

The brightener/hardener for gold plating is sometimes a metal salt such as cobalt rather than an organic material.

I am not familiar with the specific pink solutions you speak of. I suppose it's possible that some gold solutions have nano particles of gold, but in the general case, the gold must be dissolved as a salt, not be present as a particle, and I understand that small amounts of copper and silver steer the color towards pink. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Dear Sir:

I need additional info. on the answer (Ferrocyanide gold bath (late 19th century): It states 2.65 gm gold chloride, 15 gm potassium ferrocyanide

⇦ on

eBay

or

Amazon [affil link]

, 15 gm sodium carbonate

⇦ on

eBay or

Amazon]

, 1 liter of water, stainless steel anode. You also state: In boiling water dissolve ferrocyanide; when dissolved add carbon carbonate; when it is dissolved add gold chloride and boil for a minimum of 30 minutes.

What I really need to know is what, when (in the process) the kind of brightener to add to this solution and what when (in the process) the kind of cobalt hardener to add to to his solution. Please give this to me again with the included answers.

Thank You

- Brooklyn, New York, USA

July 28, 2013

A. Hi Doug. Please tell us what you are trying to do and why, because we are mixing apples and oranges in a confusing way, and I have little idea what we're even talking about :-)

Cobalt additives and organic brighteners were certainly not used in 19th century gold plating formulas. Thanks.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hello Ted: It is my understanding that the formula I originally quoted, can be used to Gold plate an object.

It is also my understanding that adding a brightener to this solution (self explanatory) and adding cobalt to this solution will help produce a finish which is termed hard gold. Is this true or false? Thank You.

- Brooklyn, New York USA

August 2, 2013

A. Hi Doyle. It's more false than true.

Sorry for the communication difficulty, but when I asked you to please tell us what you are trying to do and why, I didn't mean what two or three chemicals are you trying to mix . . . I meant why are you trying to formulate a gold plating process, particularly one from the 1800s, what do you hope to plate with it (jewelry, electronic contact tabs, etc.), and to what end?

by Reid & Goldie

-- hard to find & expensive; if you see a copy cheap, act fast!

on eBay or Amazon

or AbeBooks

(affil link)

You are clearly welcome to try to formulate a plating bath yourself, but just in case you don't know, people generally buy gold plating processes rather than formulate them because a thin non-porous layer from a proprietary bath costs much less and performs better than a thicker layer from home-brew, plus you get the benefit of the supplier's knowledge. In my own career of 40+ years in the industry, I don't recall a single plating shop that made their own gold plating solution from commodity chemicals (although some held as trade secret their manipulations to get certain properties like specific color).

Let's start with a table from Gold Plating Technology: .

You are trying to start with a 19th century ferrocyanide "color gold", and trying to add cobalt and/or an organic brightener like EDTA to it as if it were an acid hard gold plating solution. I don't think there is much chance for success. For one thing, you must be well into the acid range to get the cobalt to deposit. Further, quoting D.G. Foulke, in Goldie again, "The preparation of gold baths using potassium ferrocycanide goes back some 150 years, when alkali cyanides were impure and expensive while potassium ferrocyanide was fairly pure and cheap". The overall thrust of his comments is that the ferrocyanide itself has been found to not actually be a part of the process, and it's silly to use ferrocycanide now that we know better.

If you are looking for a "hard gold", this would be the "Acid" gold in Goldie's chart, with a simple cobalt salt added so it co-deposits as an alloy of perhaps 0.5% cobalt (although I understand that it's often premixed into the gold solution), and perhaps EDTA as an organic additive. So the direct answer to your question of when they are added is: not in the initial compounding, but after the initial compounding is done. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

August 14, 2013

Q. Hi Ted:

A Mr. Gordan Budija suggested the following formula for a gold bath.

Ferrocyanide gold bath (late 19th century):

2,65 gm gold chloride

15 gm potassium ferrocyanide

⇦ on

eBay

or

Amazon [affil link]

15 gm sodium carbonate

⇦ on

eBay or

Amazon]

1 lit water

Stainless steel anode, 2-6 V / 0,5 A/dm2

In boiling water dissolve ferrocyanide; when dissolved, add carbonate; when it is dissolved add gold chloride and boil it a minimum of 30 minutes.

Must be filtered (cold) and then you can use it. Never mix it with acids!

Only grease and oxide free objects can be plated!

Can this solution be used to plate a brass object? Is this

to be used in the normal electrolysis process or is this to be used in the brush-on method?

- Brooklyn, New York, USA

A. Hi Doyle. Further up the page I remarked that I didn't think anyone had heard of brush electroplating in the 1800's -- so I presume the formulation is for normal tank plating. I know of no reason why brass cannot be the substrate to be plated with this solution if we make the leap of faith that it works at all :-)

But I'll ask for the third time what you're trying to do -- because it is not our intention to lead you down dead ends, or toward dangerous chemistry, or obsolete processes, while leaving out important things you should be told . . . but there's no way we can even guess what you're trying to do or why, and therefore what we should be trying to advise you about. But best of luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hello again Ted:

All I am simply trying to do is gold plate a few brass pendants. Will this process work?

Doyle Whitaker [returning]- Brooklyn, New York, USA

August 16, 2013

A. Hi. I have no experience with this 150+ year old process, but Goran is a metals conservator who feels it will deposit gold, and I have no reason to think it won't. But I'm still wondering why you're trying to do this rather than simply using a modern plating solution, but best of luck with it.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. This type of bath is very stable, relatively simple to prepare, without any free cyanide, and you can use it to gold plate brass (or any other copper alloy), silver, iron and pewter (according to J.Fischer, D.E.Weimer, Precious Metal Plating [on Amazon affil links], Teddington 1964, p.115). That type of bath is oldest cyanide-free gold plating process: 1841! (according to other sources thiosulphate bath). According to some sources still in use in Russia (Halilov, I.H. Galvanotehnika Dlya Yuvelirov,plating Handbook for Jewelers, Saratov 2003, p.38).

Hope it helps and good luck!

Goran Budija- Cerovski vrh Croatia

Dear Mr. Goran Budija:

Thank you for your response to my question. I have a few additional questions I would like to ask you also before I get underway.

(1) You state: This type of bath is very stable, relatively simple to prepare, without any free cyanide ... I want to clarify this one point. Since you are mixing potassium ferrocyanide

⇦ on

eBay

or

Amazon [affil link]

with boiling water and this already contains cyanide, wouldn't this be a dangerous thing to do?

(2) If the pendants I plan to plate are approx. 1 inch square, how many pendants of this size would you estimate this solution will plate?

(3) What is the gold karat value of this solution? Would it be equivalent to 10kt, 12kt, 14kt, 18kt, or 24kt.

(4) Can this solution be used in the both the electrolysis

and the brush on process?

(5) When gold plating with this solution, is it necessary to wear protective equipment like face mask

⇦ on

eBay or

Amazon [affil link]

, gloves

⇦ on

eBay or

Amazon [affil link] , apron

⇦ on

eBay or

Amazon [affil link]

, booths etc.

Hello Ted:

The last time you responded to one of my inquires you wrote: "... I'm still wondering why you're trying to do this rather than using a modern plating solution ..."

Please answer the following question for me: If I wanted to use today's modern plating solutions, where would I obtain the necessary gold salts (I think that's what they are called) and the other necessary chemicals to make the solutions?

- Brooklyn, New York, USA

A. Hi Doyle. I think there is an assumption here that users make gold plating processes by buying individual gold salts and other commodity chemicals and mixing them. But these days we tend to buy a ready-to-go precious metal plating solution, or perhaps a make-up solution and a replenisher.

Large buyers would go to plating process suppliers like Technic or DeGusa; smaller buyers would go to jewelry supply distributors like Grobet to buy processes like Clean Earth plating solution, or to hobby-scale suppliers.

For brush plating it is usual to go to a supplier who offers both the equipment and chemicals. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. Somewhat late response:

(1) potassium ferrocyanide

⇦ on

eBay

or

Amazon [affil link]

MSDS CAN BE OBTAINED VIA WWW - MIXING IT WITH WATER ( OR ALKALINE compounds) IS NOT DANGEROUS, BUT NEVER TRY TO MIX IT WITH STRONG MINERAL ACIDS!

(2) ??????

(3) 24 ct

(4) YES

(5) YOU CAN USE GLOVES AND SAFETY GOGGLES

Hope it helps and good luck!

- Cerovski vrh Croatia

Q. Hi all. I want to do gold electroplating with PGC salt that I produced. I found that one of gold bath ingredients should be additives and brightener. But I don't know what that is. I mean If I want to make this bath myself, what component I should add to have bright gold deposit for flash gold plating?

And what material should I add for hard gold plating?

Thanks so much.

- Isfahan, Iran

October 15, 2014

|

A. Hello Neda, Process Engineer - Phoenix, Arizona USA A. Hi Neda,  David Shiu - Singapore |

![]() Hi Dear Mark and David.

Hi Dear Mark and David.

Certainly these will be helpful for me.

Thanks a lot.

- Isfahan, Iran

October 21, 2014

Gold brush plating solution in India

June 26, 2016Q. Hello sir

I purchased a brush electroplating machine last month. The machine manufacturer gave me 20 ml of gold liquid with the machine, which was made from 2 grams of white gold powder, and I paid around 100$ for the 20 ml of gold solution.

I am making inexpensive home made copper jewelry and this is too expensive for me; now I want to give a gold shine using something cheaper.

Kindly suggest a cheaper way to make the copper shine like gold.

Is it available in indian market?

I hope you help me.

Thanks

jewellery making - india jaipur

A. Hi julaha. A crucial parameter when purchasing gold plating solutions is the gold content. That's how you know if you are getting gold or water. Everyone knows the approximate price of gold on a given day. Then if you are paying only 50% more than the price of raw gold for gold properly dissolved into a plating solution, you are probably getting a great deal; if you're paying 500% more, you are getting a bad deal. If a vendor won't tell you the actual gold content of their plating solution, so you can figure it out, you're buying from the wrong people. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hi to all. I have a small company of jewelry silver and I want to make silver-gold plate (pink, black, and platinum).

Can anyone share with me a formula which has tried and has good results in these 3 colors?

thanks

- athens attiki greece

November 26, 2016

!! opinion! I am disappointed in this forum when people rather not answer questions and say go talk to a company or read literature.

Guess what, I talk to a company and read literature and I ask questions here to expand my horizons. If we want to further this field it will require R&D that starts from the basic chemistry and process. I am fortunate enough to have budget and connections that can be used to get free literature and to purchase from a company.

But the true innovations will occur when the chemistry and process is designed by yourself.

- San diego, California

May 14, 2017

![]() Hi Alex. You're certainly welcome to be disappointed; and you're also welcome to post your questions and see if they are answered -- we have tens of thousands of well answered questions in this forum.

Hi Alex. You're certainly welcome to be disappointed; and you're also welcome to post your questions and see if they are answered -- we have tens of thousands of well answered questions in this forum.

Although we happily offer grade school children detailed instruction on how to do basic zinc & copper electroplating for the purpose of understanding the science of it ("How Electroplating Works"), every science & technology quickly advances beyond what can be explained in a couple paragraphs, and we have to move on to textbooks for deeper understanding, and to sponsored research for further development.

People might post questions on gene modification on other boards, but no one would ever expect to learn the field that way; nor expect people to explain the details of the trade secret splicing tools their employer has developed ... yet because plating was done in high school chemistry class to help demonstrate electrochemical concepts, people sometimes feel that plating must be easy, and the experience & learning that a plater acquires in a lifetime can be summarized in a paragraph, and that people in the plating industry have no right to intellectual property but owe the world the proceeds of their decades of research :-)

Books.google.com will have some old formulations, as will older textbooks, and scholar.google.com will show you some current research, but very few people know the formulation of the modern-day brush plating brighteners, thickeners, etc., that people are interested in; I've been in the plating industry for 50 years and I don't know them. And the few people who do know them are not permitted to blow their employer's trade secrets on the internet. Sorry.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Thank you Ted for your reply. I see the naivety in my comment now.

I have spent a month trying to electroless copper plate on plastics using my own chemistry and I got ok results. But today I used a kit I purchased from Transene and it gave me great results. In a single day. By the way I just ordered gold sulfite from Technic.

You are right. The truth is as an engineer or scientist we need to put together all of the work done by other scientists and engineers to make something even better. There is no point in reinventing the wheel.

That being said, there is a need to plate more exotic materials and to envision more advanced bath plating methods that have not yet been conceptualized. Of course the large companies realize this. But they do not know everything. Or they choose to develop for the largest market. As in electroless Cu for printed circuits boards. But there are niches such as plating very strong magnetic materials for levitation or plating super conductors or whatever. I still believe to do this it will come down to an individual mixing the basic ingredients together and developing process on their own.

- San Diego

![]() Hi again Alex. Thanks for the gracious follow-up.

Hi again Alex. Thanks for the gracious follow-up.

There are certainly applications which the megacorps won't invest money into. These pages are replete with examples of how the big-money folks are uninterested in solving even big problems let alone the small ones :-)

Vale bought International Nickel and the whole world's plating industry wasn't big enough for them to bother to make S-Rounds anymore, leaving everyone in turmoil. And this is not to mention that International Nickel's decades of being a champion for the nickel plating industry, sponsoring events and offering white papers on plating technology became quaint history. Responsible stewardship is so passé.

Elsevier Science, apparently without even bothering to look for a buyer/successor, simply closed down Metal Finishing magazine, the industry's longest running publication, and stopped publishing the industry's best known and most popular finishing handbook, the Metal Finishing Guidebook.

Henkel apparently will not let their distributors sell less than a pallet load of maskant to end customers who can't use even one drum before the expiration date; these pages are replete with complaints about such environmental travesties.

Yes, we're certainly on our own; today's megacorps have absolutely no sense of stewardship, responsibility, or the future :-(

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

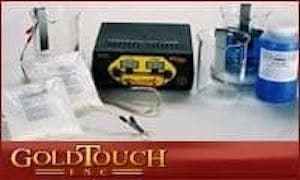

adv.

Brush plating equipment, chemicals, and supplies from Gold Touch

Q, A, or Comment on THIS thread -or- Start a NEW Thread