Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Electropolishing 17/7 PH Stainless Steel

Q. Hi,

We make small metal rings (like key rings) which are about 1/2 inch in diameter. They are made from "17/7 PH Condition A" Stainless steel wire (for the added strength and corrosion resistance). We've tried polishing these rings in a vibratory polisher but the insides of the rings do not get sufficiently polished in this manner. I've heard that electropolishing may be a good alternative and provide added corrosion resistance? Does this sound right? Any advice or other suggestions would be greatly appreciated.

Thanks,

Joe Trattner- North Aurora, Illinois, US

2003

A. We are having a 17-7 PH wire clip electropolished and it works superbly. We are using a rack method which is extremely repeatable on dimensional control.

Jim Caroll- Novi, Michigan

2004

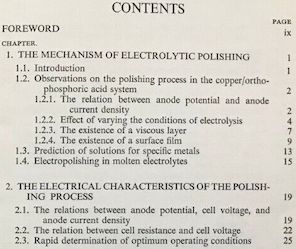

and Chemical Polishing

of Metals in

Research and Industry"

by W.J. Tegart

on eBay or

AbeBooks

or Amazon

(affil links)

Q. We have an issue with some parts we had electropolished. 10% of the lot seemed to have areas of the spring that have not been electropolished. The vendor has tried to electropolish the surface multiple times but came up unsuccessful. My question is what in the vendor's process can create this type of issue?

Chris K- Schiller Park, Illinois

August 22, 2013

September 24, 2013

A. I'm not an electropolishing guy at all, but my limited understanding is that part geometry can have a large effect on the current flow and therefore bias the EP to some areas and away from other areas of the part. I think this is usually addressed by shaping the electrodes in a way that accounts for the part geometry.

September 25, 2013

adv.

17/7 is perfectly electropolished in Universal Electrolyte. The results are 100 guaranteed. Contact us for more information

Anna Berkovich

Russamer Lab

Pittsburgh, Pennsylvania

Q, A, or Comment on THIS thread -or- Start a NEW Thread