Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

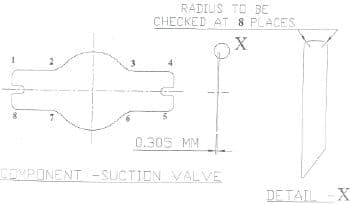

Improvement of the edge radius of the flapper type suction valve

2003

Dear sir,

I am an engineering student from CHAITANYA BHARATHI INST OF TECHNOLOGYAND and currently doing my final year project in TECUMSEH PRODUCTS INDIA LIMITED on "improvement of edge radius of the flapper type suction valve". I would like to know from you what type of the ceramic media would actually enhance the edge radius. Currently ,they are using the straight cut triangles (13mm for roughing and 6 mm for finishing)for a total tumbling time of 40-45hrs but are unable to meet the specification(35% of the thickness(15 thou). They could arrive only at 20% of the thickness. I would like to even know from you what are the different types of ceramic media available and what should be the selection criteria for a particular finishing. I would be very grateful to you if you can send me a solution in the next few days because I am supposed to submit my thesis in another ten days or so. I would be even thankful to you if you suggest me related sources where I could get any information.

Thanking you,

Shasi Chandrika Thati- Hyderabad, Andhra Pradesh, India

2003

Sir:

I am doing my final year project at TECUMSEH PRODUCTS INDIA LTD on "IMPROVEMENT OF EDGE RADIUS OF FLAPPER TYPE SUCTION VALVE".

The suction valve is made up of spring steel 2" long 1"wide and .015" thick .There is slot at both the ends with radius inside. Slot width is 0.096".As per specifications edge radius of the valve should be 25 to 40% of the thickness but currently obtaining only 15%. The valves are tumbled for 48 hrs with 13mm(rough finish) and 6mm(smooth finish)straight cut trianglar media.

We requst you to suggest us the proper type of media (cylindrical, tri star, trianglur, etc, or angular or straight )that would suit our problem. We would be grateful to you if you could send us the corresponding literature.

Thanking you,

Shasi Chandrika- India

Q, A, or Comment on THIS thread -or- Start a NEW Thread