-----

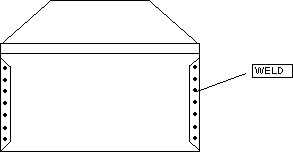

Welding thin polypropylene sheets

2003

We are producing an envelope in 500 micron polypropylene and need to weld two of the edges together. We have tried using a hot plate welder (270 °C) to create a series of welded dots along the edges but the weld is not really strong enough. Can you suggest what may be the best way of welding using our hot plate machine or an alternative method of welding which would be fast in production.

Max Hitch- Exeter, Devon, England

2003

Hi Max,

Personally I haven't a clue... but what about ultrasonic welding? This is designed for ultra thin plastics, tote bags, etc.

Even welding by hand 1/16" PP was difficult ... in fact I wouldn't even recommend it. Our min. thickness was 1/8" otherwise you'd get a lousy weld.

Also 500 microns (0.0000197"?) sounds exceedingly thin.

Another thing ... PP or Pe must, MUST be dead clean. Ideally it should be totally 'fresh' and not exposed too long to the air. If one (using a thin 1/8" sheet) makes a weld, the strength isn't all that hot until one uses a scraper to 'expose' the to-be-welded surface. This may have something to do with removing an oxidized surface a few microns thick.

A last thought... have you tried running a 'knife edge' right down that seam? Obviously the 'knife' has to be heated and ideally teflon coated otherwise it'll gum up. Just try that with an ordinary blunt kitchen knife to see if it works for you. Sorry to be negative! Nice place 'Hex-terr' good scrumpie land!

Freeman Newton [deceased]

(It is our sad duty to advise that Freeman passed away

April 21, 2012. R.I.P. old friend).

Q, A, or Comment on THIS thread -or- Start a NEW Thread