Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Coating for Exhaust System for Chrome Plating

Q. Our problem is the corrosion protection of a exhausting system of a chromium plating tank. We used "Keragelith" which is not produced any more. Keragelith was a water soluble PVC soft coating. The corrosive medium is extremely high concentrated CrO3 with Oxygen and Hydrogen gas. Which coating can we use for long-time corrosion protection of our steel construction?

Michael HekliSwitzerland

2003

A. Guten Tag Michael ... or is it Bon Jour?

Why don't you have a look at the library of finishing.com. That shows that MILD STEEL, albeit welded not sheet metal ducting, is OK. Use 10 or 12 gauge, i.e. a fairly heavy 1/l6" to 1/8" thick (depending on size)

I just don't quite understand WHY your steel is giving you problems. Maybe because it was too thin to start with or was made from sheet metal, i.e. not welded.

The only coating I can think of that is OK is PVDF ... which should last till the cows come home ... but what a waste of money.

Freeman Newton [deceased]

(It is our sad duty to advise that Freeman passed away

April 21, 2012. R.I.P. old friend).

2003

A. I would suggest taking this opportunity to very seriously consider discarding the metal ductwork, replacing it with solid PVC. I don't think I've seen a new installation of sheet metal ducting on a plating line in the USA in the last 30 years.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2003

by Larry Durney

on Amazon

(currently UTL

on AbeBooks & eBay)

(affil links)

![]() Hello Ted, hello Freeman,

Hello Ted, hello Freeman,

Thank you for your suggestions. We can't use uncoated steel due to contamination of electrolyte. We don't want to change our construction. We have got very high loads on the ducting. That's the reason why we want to coat a steel ducting.

We started some tests with different sample coatings. These coatings are very expensive (HALAR, PVDF-powder coating) or not resistant. But we still hope on a recommendation to get a less expensive solution.

Switzerland

A. Ted !

I beg to disagree.

Firstly, I stated DON'T USE SHEET METAL ... use a heavy gauge steel and WELD the damned thing.

Please contact EBCO in Vancouver.... Hugo or his son Gordon

When I moved from Toronto to B.C. in '78, my first hard chrome Dry Scrubber eliminator was for them. They still have, I believe, their original WELDED mild steel ducting. They only had to replace 2 years ago just one of the two PVC eliminator banks. ... but theirs was a WEIRD system. Their chrome tanks, due to the large diameter rolls being plated, were badly overheating. So I suggested that the PVC eliminator be split into 2 sections. The first one to be constantly sprayed with the hot chrome and returned, cooled down somewhat, to their tanks, the 2nd stage to collect the chromic fumes ... and it has, I'm told, always met environmental tests. Pretty b....y good, you must admit after over 22 years, eh?

I am a very strong proponent of PVC ... if correctly made and welded. But for hard chrome in most, not all, cases, then use mild steel. Welded. Mild steel fan. Mild steel ducting. Mild steel stack. Why waste money?

Freeman Newton [deceased]

(It is our sad duty to advise that Freeman passed away

April 21, 2012. R.I.P. old friend).

2003

Ted,

I'd like to add a 'rider' to that, if you don't mind.

P.S. If you opt for mild steel ducting, may I suggest that any 'underneath' welding is kept to a minimum, especially on longitudinal welds.

Further and more importantly, ALWAYS have a slope angle so that material, liquid in this case, cannot accumulate. Let's say a min. 2 degree slope of horizontal ducting ... this applies to hoods, too, which should have a drain off at the lower end. Sonst enstehen schnelle korrosionsproblemen an!

Freeman Newton [deceased]

(It is our sad duty to advise that Freeman passed away

April 21, 2012. R.I.P. old friend).

2003

Q. Hello Freeman,

I have got a little problem with my technical English. What do you mean with "to weld the mild steel"? Do you mean a kind of annealing or glowing by a welding apparatus?

Switzerland

2003

Michael,

Your English is excellent! Worry not!

However, I note that quite erroneously I missed replying to your statement about high electrolyte contamination in the ducting and dass ist mir Boehmische Doerfer! I just don't understand what you mean. Nor had I ever heard of anyone 'coating' the ducting...and a flexible PVC would definitely, categorically not last too long a) because it is not a pure uPVC rigid material b) because it wouldn't be nearly as thick/heavy as a PVC duct. Furthermore, one 'assumes' you just coated the outside BUT it is the inside which is verdammt wichtiger, nicht wahr?

Regarding welding, ... Ihr nennt das SCHWEISSEN ... which is not a problem for mild steel but can be for stainless (schauen Sie 6a #

19760 nach) in certain instances. Welding is just that ... it's not a vergluehen process but a zusammenschweissen ... a very ordinary and easy process for mild steel.

If you have any more questions, fire away! I'll try to answer them for you.

Freeman Newton [deceased]

(It is our sad duty to advise that Freeman passed away

April 21, 2012. R.I.P. old friend).

Hello Freeman,

I want to explain the reason, why we we use coated steel ducting.

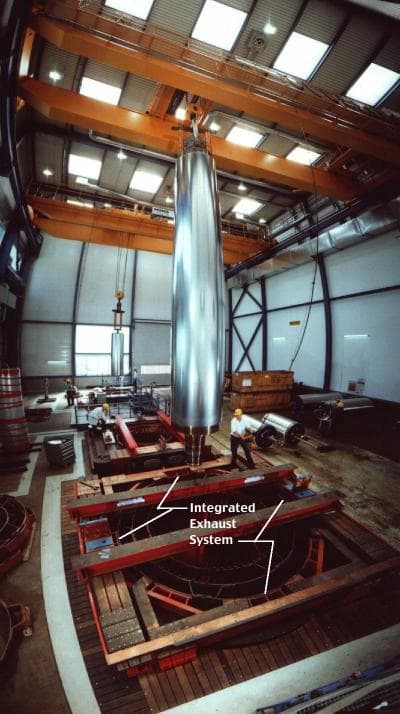

We are specialized on heavy parts and high-quality hard-chrome plating. We use a special system of chrome-plating tanks (which you can see partly on the photo).

We have got big loads on the ductings. One of the factors to reach a high quality plating is to work within very tight limits for metal impurities.

Due to the huge volumes of electrolytes and the goal to use them for a long time, we avoid Fe-contamination where it is possible. I think, a uncoated steel ducting corrodes slowly, but we get get iron in our electrolytes, when we clean our exhaust air purifiers. That's the reason, why we are looking for a good, but not too expensive coating.

Switzerland

2003

Hi again Michael !

We have got big loads on the ductings. One of the factors to reach a high quality plating is to work within very tight limits for metal impurities. I AM IMPRESSED. YOU USE VERTICAL TANKS WHEREAS THE ROLLS I'VE SEEN PLATED OVER HERE ARE DONE IN HORIZONTAL TANKS. HENCE YOUR FUMING, HEAT ETC MUST BE CONSIDERABLE FOR SUCH 'SMALL IN AREA' TANKS. SO I'D ASSUME YOU'D USE HEAT EXCHANGERS.

THEY REMINDED ME OF THE VERY TIEFEN GEWEHRELAUEFE OELBEHAELTE BEI DER BOCHUMER VEREIN AG WHICH WERE USED FOR VERGLUEHEN OF ARTILLERY GUN BARRELS WAEHREND DES LETZEN KRIEGES.

Due to the huge volumes of electrolytes and the goal to use them for a long time, we avoid Fe-contamination where it is possible. I think, a uncoated steel ducting corrodes slowly, but we get get iron in our electrolytes, when we clean our exhaust air purifiers. AH, AN UNUSUAL EXPRESSION! WE NORMALLY CALL THEM 'SCRUBBERS' (MEINE SPEZIALITAET IST JA DIE VERWENDUNG VON ABSCHEIDEPROFILEN USW BESONDERS FUER DIE CHROMANLAGEN!) That's the reason, why we are looking for a good, but not too expensive coating. YES, BUT YOUR HOODS ARE, I TAKE IT, ALSO MADE FROM MILD STEEL.

OK ... LET'S GIVE THIS SOME THOUGHT. 1. IF IT IS ALSO A DUCT TEMPERATURE PROBLEM, USE A DUAL LAMINATE WHICH IS OUR WORD FOR PVC TO WHICH FIBREGLASS IS EXTERNALLY BONDED. THEN YOU GO UP TO 85 C. 2. USE THE VERY BEST uPVC YOU CAN GET, PREFERABLY, IF AVAILABLE, IN ROUND EXTRUDED DUCTING. IF NOT, GO TO TROVIDUR AND GET THEIR 'RED' PVC WHICH IS THE ULTIMATE PVC MATERIAL. THE EXTRUDED DUCTING HAS THE ADVANTAGE THAT IT IS SEAMLESS.

I hope that that has made some sense to you and is helpful. if not, sag' mir Bescheid !

Freeman Newton [deceased]

(It is our sad duty to advise that Freeman passed away

April 21, 2012. R.I.P. old friend).

![]() What an interesting discussion. Makes an old time decorative chrome plater so grateful that we can use fume suppressants! But before the days of "Zero Mist", our mild steel ducting systems outlasted the tanks!

What an interesting discussion. Makes an old time decorative chrome plater so grateful that we can use fume suppressants! But before the days of "Zero Mist", our mild steel ducting systems outlasted the tanks!

- Cape Town , South Africa

2003

A. Plastic ductwork may not be a viable solution for retrofitting in this particular application. But, as a design guideline, I still feel it is more appropriate than steel. Some decades ago plating tanks, ductwork, grating, piping, etc. were steel whenever they could be; these days everything in a plating shop is plastic whenever it can be because it leads to a cleaner and more maintainable appearance. Decades ago wet floors were the norm, and the plating shop was off limits for tours by the execs and the chamber of commerce. These days -- as we see from your photo of a beautiful clean shop -- no area of a plant can be permitted to be a hellhole :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2003

![]() Looks like you make plenty. Don't be tight, spend the bucks. Use PVC and f'glass and stop making excuses.

Looks like you make plenty. Don't be tight, spend the bucks. Use PVC and f'glass and stop making excuses.

- NSW, Australia

2003

Q, A, or Comment on THIS thread -or- Start a NEW Thread