Curated with aloha by

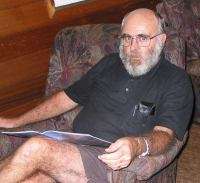

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Best Anti-tarnish for Silver Jewelry?

⇦ Tip: Readers want to learn from Your Situation 🙂

many readers skip abstract questions.

Q. What is the best solution for preventing tarnishing of decorative silver plating on small accessories?

David Harold- Newark, New Jersey

January 29, 2021

A. Hi David. My guess is that rhodium plating will be the answer you're looking for, but we've attached your question to one many long threads offering more than 150 responses depending on the situation. It's a vast subject -- please introduce yourself and your particular situation and we can surely narrow it down.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

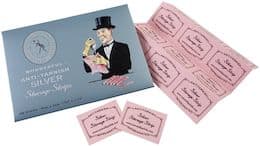

A. 3M Tarnish Strips from Amazon. (I used to work for 3M but this product line was developed after I left.) Head and shoulders above alternatives.

Tom Rochester

CTO - Jackson, Michigan, USA

Plating Systems & Technologies, Inc.

A. Try NanoTech metal coating (USA product, nanotechcoatings.com/metal-coatings/metal-coating)

Hope it helps and good luck!

- Zagreb Croatia

A. Polish it mirror bright, clean thoroughly and dip or spray on a tarnish inhibitor containing benzotraizole.

Do a Google search for such products.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

⇩ Related postings, oldest first ⇩

Q. WE ARE AN IMITATION JEWELRY MANUFACTURER IN HONG KONG. FREQUENTLY, WE ARE PRODUCING JEWELRY IN SILVER PLATED. HOWEVER, THE SILVER COLOUR WILL TURN YELLOW AFTER 3 TO 4 MONTHS. CAN ANYONE HELP ME ON THIS MATTER? OR CAN ANYONE INTRODUCE SOME ANTI-TARNISH AGENT TO ME?

THANK FOR YOUR HELP!

ALAN CHANMANUFACTURER - HONG KONG

1998

Ed. note: To make stuff more easily findable we moved a copy of this question, and the responses which suggested 'chromate conversion coating' to thread 18314.

A. We have found electrophoretic lacquer to be the most effective tarnish prevention on decorative silver. We have used it for over 7 years with excellent results.

Bob Lynch

plating company - Sydney, Australia

A. Bob mentioned electrophoretic lacquer, well, this is the best solution for tarnish prevention on silver. Actually the silverware in the British Museum in London is protected with electrophoretic lacquer. The only problem is that it is quite expensive.

Sara Michaeli

Tel-Aviv-Yafo, Israel

A. Have you considered wrapping jewelry in a protective paper. We manufacture a product called silver saver. You could place jewelry in a plastic bag with a piece of silver saver paper and it would remain tarnish free for quite some time.

M. Lawrence Garman- Burr Ridge, Illinois

1999

A. To help prevent your silver jewelry and products from tarnishing: Store your silver pieces in zip-lock plastic bags along with a small piece of aluminum foil.

Mark Cunhafine jeweler - Malden, Massachusetts

1999

Q. Dear Sirs

We manufacture Silverplated Tableware and Giftware products made either from Cold Rolled brass sheet or else Sand Casted from Brass scrap. A major problem is with regard to tarnishing of the Silverplate. We would be grateful if someone could provide advice on how to prevent tarnish, at least till the products are on the shop shelves... maybe three to four months, if not longer.

Two parameters are important - the mirror bright shine or colour should not change substantially and the prducts should still be "food safe ".

Thank You

Deepak Whorra

silver craftwork - New Delhi, India

1999

A. Dear Deepak,

Try 056 from Atotech or if you find it costly use a similar product from Progressive Chemicals Bombay. Both these need to be plated on .

If you prefer to use only immersion type of anti tarnish, GTZ and Chemitall Rai also have excellent products.

Regards,

Khozem Vahaanwala

Saify Ind

Bengaluru, Karnataka, India

Q. We produce silver filigree, our first problem is the silver tarnish and cleaning after. Please help me with a product for use. Thanks!

Guido F. Celi- Miami, Florida

2000

Q. I WOULD LIKE TO LEARN HOW I CAN CLEAN SILVER PLATE? I HAVE A SILVER SHOP IN IRAN. PLEASE ADVISE IF YOU KNOW OF ANY WAY TO KEEP THE SILVER PLATE CLEAN! (AFTER SEVERAL WEEKS, SILVER PLATING BECOME OXIDE)

Babak JahromiC.I.C. - Iran

2000

Prevention of silver tarnish

Q. I need information related to prevention of silver jewelry from tarnishing either by adding some other less costly metal or by coating it with an invisible polymeric coating.

Dr Padma S VankarFEAT laboratory, IIT Kanpur - Kanpur, Uttar Pradesh, India

2002

A. Since you are from IIT, you can do some basic research.

Try this : Plate on an alloy of Silver and Germanium(about 1 to 5 % Germanium)- Marc De Bonte published a paper in 1993 on this.

After plating, heat for an hour (about 120 °C) ... this will solve the tarnishing problems.

Deepak Whorra

silver craftwork - New Delhi, India

2007

Q. Is there a way to prevent silver from tarnishing or at least slowing the process. I can polish it but it would be nice not to have to do it every other week. The silver is kept in a closed cabinet but the cabinet isn't air tight.

Thanks,

Cori Oxmaneducation - Seoul, AP, South Korea

2004

Q. How can I protect silver from getting black in a window-shop.

Jan Groosgoldsmith - Den Bosch, Noord-Brabant, The Netherlands

A. Dear readers, we have a lot of questions on line about this subject and there isn't a "single best answer" that covers all circumstances.

There are a number of different anti-tarnish approaches ranging from the chemical chromates and electrolytic chromates to the electrophoretic lacquers already mentioned, through single component and 2-component clear coats, radiation (UV) cured coatings, organic preservatives, rhodium plating, etc. You can read about all of them through patient application of our search engine.

Or, an article entitled "The Protection of Silver Against Atmospheric Attack" by Gay, Berçot and Pagetti, published in the May 2004 issue of Plating & Surface Finishing may help you decide between the many options for preventing tarnish. Good luck! Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. My name is Deepak Whorra, a fourth generation Silversmith.

The demand for Sterling Silver is reducing very very rapidly, primarily due to tarnishing issues and people having no time or inclination to polish off the tarnish. So I am doing research on what system/method to use to prevent tarnish:

1) E.Lacquer: Good protection but can reduce gloss, needs a well modulated and controlled plant with almost continuous operation, is quite expensive per square foot,etc. And not recommended for food containers. Also yellowing after some time.

2)Proprietary anti-tarnish dips - Per sq foot cost is reasonable though not low. But life of protection is very much less especially in Delhi's polluted ambient air.

3)Chromate based Dip coating : Cheap but protection life is poor.

4) Electroplating of chromate based chemicals like Tarniban,etc.: Decent life span and economical though not suitable for food containers. Effluent treatment can be problematic though.

My questions :

a) Why is everyone constantly telling me not to use Chromate passivation even for decorative products?

b) A second, maybe stupid , question- In India Teflon coating is applied to cars and they do not change the colour but I am very happy in applying this to my cars. Is this possible on silverware without affecting the gloss or colour and will it protect against sulfide?

c) A third question : Is there any progress on initial research done by Marc de Bonte on coatings of Silver-Germanium alloys ?

d) Any other solution ?

I know that this problem would have been posted many times but I do wish some answers to this in view of new technologies over the past few years including nano technologies. Not one person has given a satisfactory reply to this question specially if it refers to anti-tarnish on food containers.

I don't believe that there are no totally satisfactory answers in this day and age that satisfy all requirements like long life of anti-tarnish, no change of colour and appearance, non-toxic and easy to control pollution ( Cr+6 free ), and economical too. I feel that answers are hidden somewhere with proprietary manufacturers who are not forthcoming since this would kill so many existing products.

The simple way to analyse for chemical companies would be :

coating has to be thin and non-toxic, hard so as to last for a longer time, totally transparent so as not change the look, and then so many options would come

Come on you people are such big companies with state of the art research facilities ... the market could be bigger than Viagra for the first one to come out with a solution.

Deepak Whorra

silver craftwork - New Delhi, India

2007

A. Hi, Deepak. The answer to "a" is that chromate is considered by some governments to be carcinogenic and its use is severely restricted by RoHS and similar standards.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi Ted,

Thanks for answering one of my questions... Do you think that that CR6 usage is dangerous ?

What about nano technology coatings or Silver-Germanium alloy coatings ? Any further developments on that ? I am very keen to know because these maybe the only long term solutions for the moment

Deepak Whorra

silver craftwork - New Delhi, India

A. In this context -- for use on a food container -- yes, I think chromate is dangerous. Although I've mentioned some articles about tarnish prevention from time to time, sorry but I can't tell you the ideal approach for your situation or provide more insight into your propositions.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

A. Try Argentium(R) sterling silver-according to producer that silver alloy(925 parts silver/rest copper and some germanium)is very resistant to tarnish( and more expensive than ordinary sterling silver). Hope it helps and good luck!

Goran Budija- Cerovski vrh Croatia

Q. Is there a practical and safe way to apply lacquer to silver/plate to prevent tarnish? I've sprayed acrylic lacquers, but it makes the finish so dull that it's unattractive. Thanks

Kathy Tconsumer - Chicago, Illinois

April 17, 2008

A. I have finally hit upon the right Lacquer that is so easy to apply, does not affect the shine (98% on a glossometer), and quite economical too

Deepak Whorra

silver craftwork - New Delhi, India

July 19, 2009

![]() Hi, Deepak. You came to this page two years ago lamenting that people were not forthcoming enough :-)

Hi, Deepak. You came to this page two years ago lamenting that people were not forthcoming enough :-)

So we encourage you to publicly share the information you have now acquired. Thanks!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi,

I wanted to know if anyone has heard of or used alkanethiol self assembled monolayers (SAMs) as a means of preventing oxidation of silver. I know from my experiences with SAMs and some XPS work that the SAMs prevent oxidization. I have also read some papers about it too, and they also agree. But I have not found any papers that talk about the long term mechanical strength of these SAMs. So is it feasible to use SAMs as a means of preventing oxidation of silver parts that are handled often, but with only ones hands.

Eric

hobbyist - Massachusetts

July 20, 2009

Q. Can we plate an alloy of silver/Copper/Germanium ?

Deepak Whorra

silver craftwork - New Delhi, India

July 18, 2009

Q. Can somebody tell me the latest technology for silver anti-tarnishing?

Deshaka Kottage- Colombo, Sri Lanka

January 22, 2010

A. Hi, Deshaka. There is no "silver bullet" to prevent silver from tarnishing. The approaches include chromating, putting organic corrosion inhibitors on the surface, rhodium plating the items, lacquering them, electrophoretic lacquer, SAMs, using corrosion inhibiting packaging, etc.

Some approaches will be good for some applications and poor for others. For example, treating a sealed electronic component with chromates may be a good answer, but treating a food service item with toxic chromates would be a horrible idea. Please describe your specific product and application, and the environment that the parts will see, and people will probably be able to help you make a selection. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. We are a small factory in Guatemala, Central America.

We make jewelry in silver.

We are interesting to prevent tarnish over silver pieces.

We need some kind of dipping what make this function.

MANAGER OF FACTORY - ANTIGUA GUATEMALA

May 10, 2011

----

Ed. note: Readers please see thread 18314 for a discussion of chromating of silver, and thread 3755 for more discussion of clear coats on silver.

Q, A, or Comment on THIS thread -or- Start a NEW Thread