Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Recovering gold from electronics, page 4

October 11, 2010

Hello, I just acquired a good number of riser cards from some very old HP lab equipment - The most advanced IC's on the boards are proprietary ~10-pin IC's, no microprocessors or anything. Any attempts to date these boards has failed. I believe they were used for some sort of RF system, possibly signal generators or something like that. They all have card-edge style connectors on the sides, and HP numbering on them.

ALL of the traces on all of the boards are 100% gold looking - There is no "green-screen" on any of these boards, and interestingly, some of them almost look like the traces were machined instead of etched.

Does anyone know how much these would be worth? I am just looking for a ballpark figure, I am a college student and I would like to try and sell them on eBay.

Thanks in advance!

Student/Hobbyist - Howell, Michigan

October 13, 2010

What everyone is trying to do or seeking here is called "HYDROMETALLURGY" a complicated, multi-metallic extraction process.

I see over inflated estimates, deadly processes and just plain stupidity here. The aforesaid mentioned processes, even those trying to be "green" are full of errors, deadly and down right WRONG. Uneducated use will KILL you or your family. Do it right or not at all. Take a high school or college level chemistry course, understand the difference between an ion, atom, and protons, what pH means (critical to hydrometallurgy) redox chemistry (also critical), know how to use a chart of metallic valences and what that means. etc, etc, etc.

A. You will NOT make money at this, PERIOD. Most intelligent people realize this sooner or later... the companies selling chemicals or "magic leachants"(acidic or basic formulas, bromine, chlorine or iodine chemistry or deadly sodium cyanide, nitric acid, equipment, etc) will be making "gold" from your foolishness, you will end up disappointed and maybe dead, crippled, blind or VERY SLOWLY DYING.

(Most chemical poisoning is LONG term, accumulative and unnoticeable in the short term, years later you may become blind, missing teeth, or even have heart or lung disease, breathing problems or even worse.)

B.Many states now make it a FELONY to possess chemicals of certain types, chemical glassware, etc. (Thanks to the idiots operating meth labs). I have a LICENSED Assay and Recovery Lab here in Texas. The licensing Authority is the Department of Public Safety, Drug Enforcement Division. Ownership of a single beaker in the state of Texas can result in high fines and a stretch in a Texas State Prison, and you are a convicted felon for life. A licensed lab is also subject to an unannounced inspection at any time during work hours by the DPS, EPA and the local fire department.

C. State and Federal EPA and Law Enforcement agents are proactively searching out illegal labs and a legitimate chemical house will be in deep crap if they sell to someone if they do not have proper documentation and will report YOUR purchase to the State and Federal DEA, EPA and possibly the FBI as required by state and federal law. I've seen this happen in Texas, California and Oklahoma, it's no joke! Be an idiot and pay the price!

D. Sell your scrap to a reputable refiner, David H. Fell in L.A. California is where I send my scrap, dore' or fine gold, it is NOT worth your time, effort or safety to attempt this at home. I usually take my gold to 99.98 fine and get a return of 97%. I have used them for 18 years, always fair, always prompt.

E. How do you KNOW that you have pure gold? How do you assay it? Do you even know what an assay is? One single typical "OLD" motherboard has less than $0.50 values in it at current gold prices. (10/12/10) Do the math! Others here have made outrageous claims as to the values recovered.

F. Amman and others have published very good books, some indoor suggestions are foolish and should NEVER be done in your basement or garage, BUT FAILURE to follow proper PPE (Look it up!)procedure as described time and time again, because YOU THINK YOU KNOW BETTER is totally stupid. YOU CAN ACCIDENTALLY CREATE EXPLOSIVE GASSES and POWDERS (Fulminates, mercury, lead, gold, silver and other metallics) from the chemistry involved. Explain that to the Police, Fire Department, EMT's, EPA, your insurance companies and your pissed off neighbors why your house or garage is laying in their yard or why their dog, cat or child is dead.

PLEASE UNDERSTAND, you are doing a VERY DANGEROUS process.

Remember, this site is about metal finishing, which requires training and schooling to do it properly.

Electrochemical Engineer - Alto, Texas

Hi,

I wish to find a honest-fairly honest metals firm to melt down and reclaim my gold scraps. I have collected 5-10 ounces of gold in various karat weights. Simply, I was a student of jewelry and collected all my broken stuff. Can anyone suggest where I can find a gold scrap reclamation company? One that won't just rob me (completely)?

I could torch everything into a mass-ingot, but that is still going to leave me with a selling problem for my odd karat mixture of gold and other various metals.

There are many posts about all the processes of separating metals, but the chemicals and the experience are lacking in my case. Therefore, I would not like to develop cancer or lung problems for a few ounces of gold whatever the price.

The internet searches have led me to many dubious sites.

- Denver, Colorado, USA

November 4, 2010

----

Ed. note: Recommendations from people you don't know, on an internet that is full of scammers, spammers, and shills posting with fictitious names and posing as satisfied customers is not the place to get a solid commercial recommendation Mark :-)

To try to insure that this site does not become one of those "dubious sites", we print only technical recommendations, not commercial suggestions. Please look in the yellow pages, drive around your town, or check the trade journals serving the recycling industry and decide for yourself who looks honest and reputable. Good luck.

February 28, 2011

Hello,

To whom expertise,i am student from Malaysia. I am doing research about LCA in extacting gold. I needs to know the contents of gold stripper and also their percent. So, that I can knows the environmental impacts of gold stripper.

regards,

Fida

- Malaysia

Hello everyone, I've been using the AP method to recover gold from electrical parts. For the first time I had a white paste drop out of the mixture. Would anyone know what it might be? Thank You.

Rhett Kirklandsilversmith - Archer, Florida, U.S.A.

March 8, 2011

Regarding the old cell phones or circuit boards from cellphones, it's a lot of trouble, it will not yield enough results from the amount of labor you have to put into it. You are better selling to a place that specializes in cell phone recycling and just moving it. Not to mention the danger of doing it yourself..

Jason Lee- Orlando Florida

May 6, 2011

A while back we needed to sale a lot of gold jewelry. I had maybe about 2 pounds, sorry to say diamonds too. I got around 2500 dollars, so I got very interested in it. could you help me in knowing what has the most gold content?

Terry Hardyhobbyist - Lenoir City, Tennessee

May 10, 2011

Great information everyone, I come here to read and compare notes based on my experience of less than 6 months in e-waste. I would like to speak to retirees, disabled individuals working at home for a little extra money. Instead of sounding like I know a lot, I will say I know about 3 useful things so far.

#1. Handle Volume

#2. Get paid for Scrap metals

#3. Save up Gold

If you put yourself in a position to recycle all metal (gold is the last on my list), you can recover approx $5 per old computer (20-28 lbs per computer tower). This is scrap steel, aluminum and copper in various grades and quantities. You break everything down into buckets of similar parts. Even hard drives are separated into little tiny pieces...I even save the platters for their 0.10 value of platinum. Power transformers 0.22 lb/copper wire(#3 copper)1.10 lb/ motherboards 2.00 lb/hard drives(aluminum) 0.80 lb/gold plated chips & ram(?). Go to your local recycling centers and show them what you have, you will learn exactly how much you can get locally for the basic metals. This is 2011 prices mind you, not 2007 when some of these threads were started. Save all your gold pieces and tuck them away, forget about them until you have about 20 lbs of various shiny goodies. Meanwhile, you can go buy a dead computer for about a buck and make about $3 profit...if you buy a lot of computers at a time. Volume is the key to making any kind of real money. I bought 100 old computers for $125, that's $500 at the scrap yard/e-cycler. The mother boards are selling for $2/Lb in Atlanta...you will have to make some calls for yourself to find the right one in your area. What the local scrap yard won't buy, the e-cyclers will. So you can take 4 computers apart per hour, 4 x $3 profit is $12/hr to sit at home and tinker in the shop. I wouldn't take out a mortgage on that, but it's extra money you can see within a few days vs. all that investment and risk just to get a little gold.

If you're like me and looking to make a few bucks without spending a fortune on equipment/chemicals/etc., you can work in your spare time sorting out and disassembling computers, dropping off at the scrap yard and when you have enough gold scrap pieces, cash in. Think of it like a 401k, 401,000 computers later and you're a millionaire!

For you guys buying gold scrap on eBay , put an ad your local paper and offer to buy old broken gold jewelry. Pawn shops do their homework and identify gold jewelry, pay about 25-35% of what it's worth, mail it in to a refiner and get a check for the balance. That's better (in my opinion) than buying E-Scrap just to get gold and discard the rest. There's more in scrap metals in each computer as far as my beer money is concerned :)

Lastly, you folks who say things like 'save the world' and 'environmentally safe fumes', etc...I would like to point out the fact that every computer board that is recycled, gets shredded and burned for recovery. Just like copper, steel, plastic, aluminum, rhodium, platinum. When you rush off to save the world by sending all your computer scrap to a big refiner, they are burning it all, plain and simple. They have the tall stacks that burn the smoke so you don't see how much pollution they are putting off. The responsible secondary smelters use scrubbers that collect the most deadly chemicals, but then that has to go somewhere. If you make recovery a lifestyle and earn as you go on the side, you don't feel so bad about recovering some gold and killing the little fishies! Lastly, the day will come that e-scrappers will exhaust the good stuff...high yield gold, blah blah, scrap steel, copper, aluminum will always be available and resources are being tapped at an alarming rate. China is buying everything we recycle for a reason. Your plastics are also worth $0.06/lb, so when oil continues to rise, plastics will also rise and soon plastic recovery will be on my list of things to collect for foldin' money.

Stay Safe!

- South, Alabama, USA

Not that anyone cares, but I'd still like to say:

I'm not particularly interested in trying to get gold from scrap. And DEFINITELY not for money. I am, among many other things, an artist, and I DO have definite interest in acquiring gold and silver for several of my projects. I found this site when looking on google to see if there was a simple way to separate gold and silver out of silver-plated, gold-plated, and gold-filled jewelry, such as simply heating it up and melting it apart in a crucible, or anything like that.

However, I have read this entire thread, every word, from top to bottom, and all I can say is... I am HORRIFIED. Chemistry is not my thing - I was good at it, but it never inflamed my imagination and passions the way the subjects I truly studied did. But even with just the minimum required chemistry to pass high school, and the mandatory general education courses in college, I can see that less than 1/10th of the people who have posted here should, logically, still be ALIVE after what they claim to have done/attempted.

Granted, gold is a fascinating material/substance for a vast number of reasons, the LEAST of which is it's dollar value. But to do things so boneheadedly stupid, just to get a small quantity of it... I cannot fathom it, I really cannot.

You want to recover it? Use the razor blade method a few people have mentioned. That's the ONLY safe method mentioned here. The rest... don't do it. Just DON'T.

I'm not sure what to do to get the gold and silver I need from my -plated and -filled jewelry, but I do not think I will find my answer here. Thanks anyways - and seriously, thanks for the nightmares. >shudder

- Oklahoma City, Oklahoma USA

July 2, 2011

August 2, 2011

I have very old circuit boards from IBM 360 mainframes and a few older SMS cards. I am wondering what the estimated yield would be for precious metals recovery.

I know that in the great IBM melt, when gold was $870, they were getting $22,000 per machine in gold, plus some platinum, palladium, silver, etc.

I am unsure if any specific part had more than others.

Is there anyone familiar with these old computer parts still out there who can provide additional information?

- brooklyn, New York usa

Hi, I took apart lots of electronics and I have a lot of circuit boards and chunks of jewelry. I was planing on using aqua regia but I'm afraid how many different metals would get dissolved. I was wondering is there was a way to precipitate only the gold? If I use magnesium strips, would I only get gold? Or should if I use sodium metabisulfite, will I only get Gold precipitate?

I don't know if I should just throw everything in aqua regia, evaporate the nitric acid and just put sodium metabisulfite in it? Would that work?

Hobby - Shoreline Washington USA

August 12, 2011

OK already know there isn't much gold in Electronic parts

BUT damn it expensive sunglasses and other types of jewelry are heavy gold plating and can easily be scraped off to get gold from!

People don't bother with this stuff once broken they leave it lie on the ground!

I have 50 pairs of designer sunglasses with gold plated frames about 60 lbs of other gold plated jewelry and belt buckles and from ladies purses and hand bags!

all collected in 3 months time along with my travels in scrap metal recycling!

The pc boards I take apart and take all copper out of it at $4 a lb cleaned sure is worth it the case weighs about 20 lbs with whatever steel is left inside thats .12 cents a lb so ten of those babies = 200 lbs and a fast $24 in my pocket of course I have tools to remove screws and clips and a wire stripping machine that paid for itself 1st time I used it strips any thickness of wire in seconds!

Cost was $400 I had 200 lbs of wire piled up after two days of traveling in my tri county area from old tvs, vacuum cleaners, lamps, etc... stripped clean in 2 hrs time after insulation was removed I had 180 lbs of copper cleaned !

180 times $3.75 a lb = $675 just for the copper 400 lbs of steel and iron X .12 cents $48 100 lbs of aluminum cans .60 a lb = $60 100 lbs of aluminum .55 a lb = $55

Total time in 3 days was 42 hrs hrs gas used was 3/4 of a tank $65 dollars! NO TAX on scrap iron metal recycyling

SO now my next step is scraping the gold off all this heavy plated jewelry and other stuff I have!

Gonna take long time maybe a month and I hope to get $500 - $1000 for the gold dust!

- Phila Pennsylvania

August 21, 2011

My Company cleans up the debris many of you guys leave behind except what's left of your body after you blow you and your family up. I am HAZMAT, OSHA, FEMA Certified and have one question to ask all of you guys (Excluding Lic. Metal Refinery Corps.)? WOULD YOU WALK INTO A ROOM OR HOUSE THAT HAS AN ACTIVE METH LAB IN OPERATION? Yes it sounds like it; I don't care what degree you have you don't know what the hell you're doing, fresh out of school ready to give advice; to me thats like a General Contractor's first job rebuilding the Towers. SEND IT TO A REFINERY.

David Hoover- Ringgold, Georgia

September 27, 2011

This is in answer to a question. I have been scrapping for years in Indianapolis, Indiana. There are a number of various metal on a computer to scrap. Heat Sinks, All the electronics can be salvaged and sold to enthusiasts. The stripped boards themselves can be reused by hobbyists. Stripped out computer monitors can be stripped out as can DVD, floppy drives, etc. If it is an electronic item and you have access to Craigs List on the computer, you can sell any item. You can not just go to Radio Shack anymore and buy electronic parts. Most of the kids they hire do not know what a diode is, they would think it's a nose ring or something. Scrapping is very profitable if done right, even as a hobby.

James Brummettscrapper - Indianapolis, Indiana, USA

October 30, 2011

anyone know the best guy to send my tungsten (W)/silver alloy contactors, for refining and/or sell? I only have 7 pounds. Is there a place in China where I could send them and get a better deal? I had a guy shoot them with his analyzer and he said they have between 16 and 40% silver. Several big companies here in Dallas said they didn't fool with tungsten alloys. I have looked on the internet but the best deal I can find is 50% for them and 50% for me ... any ideas out there ? I read above that selling on eBay is a good way. What would you guys recommend?

Bill Hollonelectrician - Dallas, Texas, USA

November 3, 2011

----

Ed. note: this site is for technical discussions rather than commercial contact. Unfortunately we are instantly drowned under lengthy advertisements if we print commercial postings; worse, some vendors post with fictitious names, posing as satisfied customers :-(

All general advice for you is welcomed, but we can't print contact suggestions.

I've done research just like everyone on here. I collect computers when I can for free. Save them up, take them apart, scrap out tin, aluminum, and sometimes copper in town. If we search hard enough we will find our answers. If we choose to do it ourselves be aware its just not ourselves we put at risk. Things happens, like pets, air flow and people. I don't think too many people put too much thought into it. Sure we have our safety at hand but we forget about others. Do you have kids? If there's something you don't want them getting into, well . . . what normally happens? Anyway I found a web site that will pay you 82% of what it's worth and will even pay for shipping (from anywhere! all they ask is to have it separated and more then 25 pounds). If you search for it you'll find it.

Kirk NastFor fun - Spokane, Washington

November 6, 2011

I have seen the dangers first had of the chemicals used in the process. THINK SAFETY FIRST. I just started recovery of gold/silver from electronics by reverse electro plate method. I have researched this for about 15 years now looking for the least hazardous way. It's not fast not expensive but still has its dangers. So read a book ... listen to the experts ... study the dangers ... know what you are getting into. If you are looking to get rich, get a job.

Bill Evans- Sylvania, Georgia

December 26, 2011

Jeez, gold from E-scrap should never be considered anything other than a hobby. You will honestly make more from the copper and aluminum. It takes on average 120-150 desktop comps to make an ounce of gold.

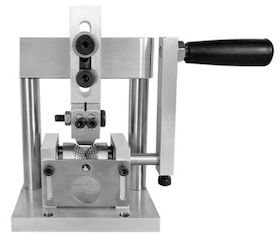

And on the subject of a stripping cell (I have made many by the way) all you need is concentrated sulfuric acid as the electrolyte and lead as the cathode while the piece being stripped is the anode. Use a 12v auto battery charger

⇦ this on

eBay or

Amazon [affil links]

with a manual setting. Very simple design is small pyrex loaf pan with a sheet of lead on one side as cathode (hook negative to this side) and the positive to the piece you're stripping. I use a copper mesh basket to hold loose pins and a jumper I made for individual pieces. Concentrated sulfuric will heat up due to its resistance and will attack copper when heated, so you have to stop and let it cool between runs. I use Liquid Fire drain opener.

The label lists the ingredient as concentrated sulfuric acid and it works great.

The gold releases from the piece due to ionic exchange and at the same time as sulfuric can not hold gold in suspension and lead is neutral, the gold self precipitates to the bottom of the cell as black powder. The solution will get blacker and thicker the longer it's used until the powder slimes reach the bottom of the cathode at which point it stops stripping and needs to be cleaned up.let the powder settles (this can take a day or more) and slowly decant the acid to another container (this can be used over and over again); be careful not to disturb the black powder and leave a small amount of acid with the powder. Place this in a separate container and replace the cathode and the electrolyte plus add enough to make up for what's with the powders and start the process over.

Clean the powder by slowly adding powder and acid mix to clean water. CAUTION: sulfuric acid does not mix well with water and will build heat quickly. Dilute with 10x water and let the powder settle and decant down to the powder. Repeat this until the water remains clear. What you have left in the powder will be about equal to 20K and will need to be refined.

Dissolve the gold powder using muriatic acid and chlorine bleach

⇦ bleach/sodium hypochlorite in bulk on

eBay

or

Amazon [affil links]

(yes,it will dissolve the gold) the solution will be green, precipitate the gold with sodium metabisulfite sold under the name Bonide stump remover.

To make it really pure, dissolve again with HCl/Cl and precipitate. This should be at least .950 if not higher. I'm not even going to get into the acid peroxide method for stripping whole boards and dissolving the base metal out of gold plated pins. I may come back here and do it later.

- decatur, Alabama usa

January 1, 2012

Readers: I've seen muriatic acid mixed with bleach, and the toxic cloud of poisonous chlorine gas it produces. I personally think it's madness attempting this kind of stuff in a residential situation.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

January 1, 2012

I do apologize about the brevity of my earlier post, and I do agree whole hearted about safety issues. All appropriate safety precautions should be taken and any process I describe should be done in a fume hood and/or with the use of PPE's. I will describe the correct use of muriatic acid and sodium hypochlorite. This process is only recommended on gold foils and gold powders but not solids or karat gold. A good respirator and a good breeze outside in an unpopulated area or a fume hood is recommended. In a clean glass or porcelain container, place your foils or powders (up to 1 ounce) and add just enough muriatic acid to cover your material. Next, add sodium hypochlorite in very small increments (10 ml's) at a time and stir with a glass rod; visually inspect the contents after each addition to insure the material has all been dissolved. It should take only 2-3 additions. If the foils or powder is contaminant-free, the solution will be a golden yellow color (auric chloride). If the material is contaminated, the solution will be some shade of the color green. If it is, not to worry, just precipitate and refine again. You leave impurities behind every time you dissolve the material and precipitate. I will describe the washes and rinses involved to raise the purity of your gold to .999 next time.

Jeff massey- decatur, Alabama usa

January 3, 2012

Home refining is only dangerous if done by individuals that decide gold is worth more than their health. The chemicals needed to refine gold can be obtained at most hardware stores and are no more dangerous refining gold than performing the job it was sold to do as long as the person knows what they are doing. Sodium and chlorine are two of the most deadly elements on earth but if you combine them you get table salt, something we all need to survive. Always use PPE's when dealing with acid. To depopulate whole boards just soak the boards in muriatic acid (HCl); it will dissolve the tin in the solder releasing the components (collect powders in the bottom of the container as this will be high content silver). For any board that has gold plated traces (including phone boards), PCI fingers, clean gold plated pins or any gold plated bits that may be trapped in plastic, AP or acid peroxide (HCl+H2O2) is the solution for this. HCl will not dissolve copper but copper chloride will. After the material is added and the acid is added H2O2 is added to jump start the production of copper chloride because of the oxidizer a small bit of copper is converted to copper oxide which in turn is dissolved by HCl and converted to copper chloride. To keep the reaction moving forward you may add a bubble stone made for a fish tank and an air pump for the same purpose. This will keep an excess of oxygen in solution and drive the reaction forward. This will speed up the process and remove the need to keep adding H2O2 periodically. This can be done in a 5 gallon bucket and as long as the material is free of tin and steel the solution can be re-used many times as long as oxygen is supplied. I didn't get around to describing the rinses and washes to raise the purity of your gold so I will be back.

Jeff Massey- Decatur, Alabama, USA

January 6, 2012

March 1, 2012

I am absolutely floored by the amount of folks posting on this thread that seem to think that folks have a secret, and that somehow they are entitled to it.

As a Master Craftsman I learned my various trades though, schooling, apprenticeships, internships, on the job training, hours and hours of research and practice.

I would bet the skill set for refining / metallurgy / would be acquired the same way. Only with much more schooling as the safety aspect and huge potential to hurt, maim, kill unsuspecting people is enormous.

The secret is Time, the knowledge is out there, if someone doesn't want to take the time to learn and are just looking for a magical formula, something tells me they are the same ones that are going to be creating a toxic waste dump, hurting themselves and other in the process.

And no it's not your right to do that, kill yourself sure, but impact other folks, land, or property no way.

I will give you a secret though, home labs like I have read about on here are worth Gold, lots of Gold to the folks that get paid to perform remediation on them in the hopes of keeping the property from being condemned.

"Google is not a substitute for Common Sense" -- me

- San Diego, California, USA

Q. Yes I'm into e-scrap I want to start a gov. Based Grant e-scrap. Curious as to where to apply. As well, my question is a friend owned a family operated TV repair shop for more than 50 yrs. He recently shut down and gave me more than 600 TV's, lcd plasma projection ext TV's ... so far I have seven 5-gallon buckets of boards, IC pcu chips, fingers hard drves, and still got 250 left. I'm just wondering am I wasting my time or will it benefit me? I wish I knew around about how much to expect.

T

- Pelion, South Carolina

August 8, 2020

A. Hello Jamie,

You will probably find obtaining a grant will be very difficult for electronic reclamation. Mainly because of EPA requirements. There is a good letter on this thread from Sam Kamees on the subject that I thought was very good. Scroll up to the letter dated May 15th, 2015.

- Winston Salem, North Carolina USA

August 10, 2020

Q. So I'm sure this will be added to an already going thread, but I had attempted a small experiment of hydrochloric acid & peroxide 3:1 ratio with an aquarium pump added and let it sit for 3 days on some fingers, pins, and chip powder (all separate) the gold easily came off the fingers, the pins took a little longer, and the chip powder ... well, it's still sitting in its container because I didn't know what to to with it. All were conducted in a homemade clean room with ventilation system that runs the air through water mixed with baking soda then out through the rest of the ducts. I always wore a full face p100 60926 respirator with gloves ⇦ this on eBay or Amazon [affil links] , and an apron ⇦ this on eBay or Amazon [affil links] . All acids were properly neutralized and any waste was disposed of through my local hazardous waste facility. (That can be expensive by the way).

I'm wondering if anyone will purchase what I have remaining from my experiments, or if I need to simply complete the process. If I need to complete the process, any recommendations on what to do with the chip powder? I'm being honest here in acknowledging that I started this without the full understanding of how to complete my process. I've got the Gold from the pins & fingers filtered from the HCl & peroxide soak, have rinsed multiple times with water, they are now all sitting in a filter of silk screen material waiting to be dealt with. As I said the chip powder is still in its solution.

Also on a side topic a friend of mine decided to try the vinegar & peroxide route and has his stuff still sitting in the solution after a little over a week. It appears clear-ish with a light blue tint. Any suggestions on where he went wrong and how he can get his gold out?

I wish I would have found this thread before starting my process -- it would have helped.

I am familiar with the basics of chemistry, and have all the safety gear and set up needed, I just need to know what to do next, please.

Also, I noticed that with regards to refining pm from electronics, a lot of people say sell it to a refinery,; my question is -- what do you do if you know the refineries around are only offering 30-40% of today's current value for PM? And my second question is related to the chemicals used in refining. One person had mentioned that local chemical supply companies offer classes. None of the companies around me are offering classes of any kind, they actually thought I was joking. I would like to gain more insight into the different processes involved as well as the precautions to take, but I am a hands-on or in person learner ... reading a book simply won't get through to my brain. Any suggestions as to how I can learn about this. I promise from now on its simply as a student not a practitioner.

- Anaheim. California

September 13, 2020

Is heating up the circuitry with a stronger current a means of pulling the gold out?

Sincerely,

- Vancouver BC Canada

March 14, 2012

A. Last year I had a local gold buyer check out some gold jewelry left by my late mother. He said they were worth more as antique items than the gold they contained. Many were gold plated or gold tone w/o markings. I asked him about using chemicals and electrolysis to strip it off and he laughed. He showed me boxes of jewelry like that in his back room and said it'd take a pick-up bed full to recover an ounce by a competent certified recycler. He doesn't buy the stuff but collects it for faith-based charity to be recycled, giving the donors a receipt for tax purposes. He lets them conjure up the jewelry's value to fit their tax needs. Sounds like a more practical method to obtain some value from junk without spending money and time to try something dubious and dangerous.

I'm taking his advice to sell the interesting items separately and donate the rest, though out of curiosity plan to try the Radio Shack etching fluid and electrolysis method first on some. I already have all the needed components on hand so won't be out anything plus the two methods seem the safest to try. I may be in for a pleasant surprise or a total waste of time.

Bill

- Longview, Texas

Q. Hi out there,

I have about 650 lbs of pay phone circuit boards made by Intellicall. They are from the 90's & early 2000's. Each one is about 10.4 ounces. Would these circuit boards be considered hi grade having any precious metals etc? Thanks

- New York

July 4, 2012

Q. Has anyone used a non-toxic approach other than Borax to extract precious metals? I heard sodium thiosulphate ⇦ this on eBay or Amazon [affil links] as a chemical to do a solvent extraction (liquid-liquid) that is non-toxic and is a cost-effective process and can be purchased where photographic fixer or where pool supplies are sold. What is the reaction if any with e-waste; is the process two step and involves another chemical to get the gold from the solvent?

Ra Releb- Largo, FL

July 20, 2012

Q. We have several old computers to disassemble. In refining gold from old computers, is it necessary to have all the pins off of the plastic before using the acid step? If so how is that done? We have tried it with the plastic and it just goes into a blob.

George Carter- New Bloomfield, Missouri

October 7, 2012

Q.

I have hundreds of pounds of computer gold scrap. If I were to hire a company to refine some of it, what percentage is normal for them to take?

For example, I send 50 lbs of scrap and they refine 20 grams of pure gold out of it. How much would/should they keep as payment?

Thanks for your time reading and answering,

novice - St. Louis, Missouri

January 7, 2013

January 8, 2013

A. To all readers of this thread,

I'am a time served Engineer and Scientist. I currently work as the Technical and Quality Manager for a ISO/IEC 17025: 2005 laboratory.

Firstly, anyone who is looking for the proper methodology to extract the precious elements from electrical equipment, there are books for sale that specify the process. I am a strong believer in copyright laws and as a inventor, with several patents under my name, I respect the fact that you should not get access to someone else's hard work and research for free.

Not to forgo the fact that if you cannot afford a £50.00 book to learn the process, you cannot afford the equipment to carry out the process. Similarly if you cannot be bothered getting the appropriate books, you will not be bothered doing it properly, therefore should quit now at this point.

For the purposes of this post, I will be working in £'s (Great British Pounds/ Pounds Sterling) as it is what I am accustomed to and have used in calculations.

I used to extract gold, silver and platinum as a past time under my own auspices. It was simply for fun. I have now given up that hobby as parts are too hard to come across. A lot of people see this as a "get rich quick scheme". I could go into things in detail but I have calculated that to get £1.00 in gold you have to spend £4.00 on components, transportation, chemicals and consumables. The loss is compounded further by adding in the time taken to complete the task as well as the cost of equipment.

There is literally no economical method to produce precious elements from electronic components anymore as sellers are asking ridiculous prices due to the huge amount of hobbyists who have not carried out any research or proper yield calculations before embarking on their pointless endeavor.

I appreciate that "gold fever" is a hard thing to shake off, and many of you who read this will still be blinded by it. I cannot change your mind set but I would still implore you to research the chemicals and methods mentioned above very carefully and thoroughly due to the sheer danger involved.

For example some may opt to use sulfur Dioxide to precipitate the Gold. To put this into real life risk, in my laboratory we use sulfur Dioxide in our Neutral Salt Spray Test chambers.

The chambers that use SO2 are completely enclosed in separate "cell rooms" that are made from poly-Carbonate panels, held up by a stainless steel frame where the frame is resin coated.

The room is alarmed with SO2 monitors on the inside and outside of the room. If the SO2 level rises above the alarm threshold the room electronically locks (and is airtight) and a massive pump creates a vacuum in the room and the system is purged with Nitrogen. The only time an operator is allowed in the room is when the test is paused or stopped (which means the system is purged prior to entry) and when they are in the room they wear a fully enclosed HAZMAT suit with independent Oxygen supply.

Our safety system costs in the region of £20,000 per cell (which is only 8 ft by 4 ft).

When working with Aqua Regia or Hydrofluoric acid they are used in a large ducted fume cupboard with strong suction. The vapour from these chemicals are incredibly corrosive and prior to venting to the outside we have filters and scrubbers in place to protect the environment.

The acids will require careful neutralisation and the removal of heavy elements prior to disposal. You will need to know how to do this properly.

Whilst I cannot stop anyone from attempting this without the proper training I am willing to give FREE advice on the proper safety precautions prior to doing this. I would rather give up 30 minutes of my time to talk to you than you kill yourself by not appreciating what you are working with.

If you insist on doing this, please be careful. You likely have no idea the hazards that await you.

In close, if anyone in the United Kingdom (or even Europe) consider doing this, you are committing an illegal act under the Waste Electrical and Electronic Equipment Directive as well as UK Waste Management laws therefore are eligible for a custodial jail sentence up to 10 years and an unlimited fine unless you have been issued the proper license for waste management by a Local Authority/ Council (who will not grant you one unless you are competent, qualified and adequately funded/ equipped).

Technical Manager, ETAS (U.K.) - Glasgow, Scotland, United Kingdom

Q. My mother used to work in electronics and she saved all the clipped wire ends off of diodes and (?) that were gold plated. Now I have about two big hand-fulls of these that are gold plated. Are they worth anything and where can I sell them? Thanks for any help you have!!

Sandy

single mom - Grass Valley, California, USA

April 21, 2013

Q. I want to harvest precious metals from electronics, I am fully aware of the dangers to myself, others and the environment along with hazardous materials collections and disposal. I want to shred the circuit boards and use electroplating with cathodes to collect the various metals, my question I am sure requires multiple answers and it is: if I shred the circuit boards can I then soak the scrap in a solution and keeping it agitated (slow stirring) with a electrical charged cathode inserted into the solution to collect the metals, and can I take the material (scrap) and take it from one solution to another (of course with thorough rinsing in between) with different solutions and cathodes to retrieve different metals? And if so what are the recipes (solutions), cathode materials and electrical charge?

Wendy Orndorff- Derry, Pennsylvania, USA

June 9, 2013

A. Hi Wendy. I don't have the answers, only the issues which you should anticipate encountering as you proceed. You probably will not be able to electrolytically dissolve the metals from shredded boards because you won't be able to establish contact. That means you'll have to chemically dissolve the metals into aqua regia, and my feeling is you won't be able to electroplate out of aqua regia because electroplating is a reduction process, and nitric acid is a very powerful oxidizing agent; further I think it will evolve mountains of NOx. But best of luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

June 13, 2013

First of all, for everyone who isn't qualified to use these methods of refining I.e. aqua regia, you need to realize the dangers in it, mainly death. No one's life is worth any amount of gold. Professional refiners can refine your materials for you. Please realize that unless you buy acids by the drum or have a professional setup, 99% of your endeavors will be only a learning experience and a loss of money, so consider it an expensive and extremely dangerous learning experience.

Shane Mornprecious metal refining - Milwaukee, wi usa

June 17, 2013

Q. I have a large number of 45-gallon drums of 6-inch wafers.

And a lot more are waiting for me to pick up & remove.

They have been cleaved and diced and on a sticky like tape.

I was wondering what the best method would be for me to remove the precious metals that are on these?

Any help is appreciated.

Thank you in advance.

- Toronto, Ontario Canada

February 12, 2014

Hi Kevin. *Step 1* is to determine the quantity and type of precious metals on them. What percentage of the surface is covered with precious metal (what metal) and what is the thickness of the plating? Not to rain on your parade but it is very possible that the plating is so thin that you'd need to strip an acre to get a gram; an "assay" of quantity as well as quality must precede every decision to attempt reclamation of metal values because you have to track the quantity through each step of the recovery process. You can't just start mixing witches' potions and hope for the best. So how many grams or milligrams of what precious metals are on each of these wafers? Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

July 2014

! Hi: I have invested time to experiment on safety measures, and I made a glovebox for 100% secure contamination of gas; after this a second machine to neutralize the acid with vapor to condenser and fusion to urea neutralizer.

If you invest a little money to make these two machines you would simplify the 50% of extraction, but the secret of all this recuperation has to be in the titration powder machine.

Salute to every one.

- Cuautla Mexico

July 12, 2014

Gold won't dissolve in 2% cyanide

Q. I have very fine 50 kilos ash of gold bearing computer mother boards, very well burnt chips, and turned into a very very fine powder in the ball mill. This ash contains 75 grams of gold. I prepared a cyanide solution of 2% concentration in 150 litres of water and put gold bearing ash into a leaching tank which very well rotated the whole stuff for 24 hours. The leach tank is a rotating tank which rotates the ash very well. The atmospheric air was incorporated into the tank from the bottom of the tank. The temperature of the tank was kept at 50 °C; all the gold particles were in contact with the cyanide solution. And once the dissolution of gold into cyanide solution was tried without heating the water. But even then the gold did not dissolve into cyanide solution. Please help and throw light on the factors that did not let the gold dissolve into cyanide solution?

Mutalashi KhanHobbyist - New Delhi, India

December 5, 2014

A. I would guess than any gold that dissolves is immediately cemented (reduced) onto the large amount of copper that is bound to be present.

Chris Owen- Nevada, Missouri, USA

December 5, 2014

Hello,

A 2% solution of Cn would not be enough to allow the gold to be homogeneous in water. Common Potassium Gold Aurocyanide (PGC) has a weight of about 32% KCn per troy oz supplied, which where the term 67.5% and 68% PGC is derived. You may be better off firing it in a furnace.

Process Engineer - Phoenix, Arizona USA

December 7, 2014

Can ultrasonics reduce the time required for leaching of gold in aqua regia?

Q. NORMALLY LEACHING PROCESS OF GOLD ORE OF 1 KG IN AQUA REGIA TAKES 5 TO 6 HOURS. I WANT TO REDUCE THIS TIME. THERE IS AN OPTION BY HEATING IT, BUT I THINK IT CAUSE LOSS OF GOLD BY OXIDATION IF GOLD IS LOW IN PURITY. MAGNETIC STIRRING IS NOT EFFECTIVE.

WHAT ABOUT ULTRASONICS IN THE BATH -- WILL IT REDUCE THE TIME?

PRODUCT DESIGNER - India, Mumbai

January 27, 2015

A. About 35 years ago, I set up a consulting client for the dissolving of karat gold scrap jewelry in aqua regia (AR), using immersible ultrasonic transducers. When dissolving karat gold, the silver contained on the surface is converted to silver chloride (AgCl). When the silver is higher than about 8%-10%, this AgCl coating can stop the penetration of the AR and, thus, stop the dissolving reaction. With ultrasonic agitation, however, the AgCl will continually spall off of the surface, providing fresh gold alloy for the acid to attack. The dissolving was probably 10 times faster using ultrasonics.

With ore, it would depend on the composition but I would think the dissolving would be faster in any case.

- Nevada, Missouri, USA

February 22, 2015

Dear Sir DEE K,

Never use Ultrasonic that may break glass beaker [beakers on

eBay

or

Amazon [affil links] . Normally gold dissolution depends on aqua regia conc., material surface area, heating, imp is material composition contents.

cac admixture - Mumbai, India

March 22, 2015

!! Actually if you study and know what you're doing, recovery of gold from E-scrap can be very profitable. If you recover gold plated fingers and circuit boards you can use AP solution which, if done right and taken care of, will last indefinitely and your cost of acid being very inexpensive. To date I've recovered about 40 oz. of pure gold and I've maybe spent 5-6 grand for 40 oz. or roughly $52,000 dollars in gold minus my investment of say even on the high end $10k. I still made a profit of 42 large and if you know how to process your waste as well there is no environmental impact either. So solution is fairly easy to treat for disposal.

However I strongly recommend anyone who wants to try their hand at recovery and refining of precious metals should definitely have the proper training and skills needed to do so. Either by going to school and learning or by being trained hands-on by a professional. I have my Masters in Chemistry and a full lab at my disposal. And I don't recommend any hobbyist to try this; most likely you will hurt someone or yourself and possibly maybe even end up doing hard time in prison. Some of the acids used in refining are the very same ones used to make very dangerous explosives. Don't take my warning lightly -- I am a pro and even I have made mistakes that, had I not been in a lab with proper safety equipment in place, could have killed me and everyone around me.

Adam efthimiou- Ashland New Hampshire USA

February 20, 2015

May 13, 2015

! Electronics has been my passion, hobby, and career for 50 years, but I have only been salvaging electronics for their values for the past 2 years.

Firstly, let me say that there is money in the salvage business and precious metals is only a part of it all. I make more money in segregating the metals whether ferrous or non-ferrous, precious or non-precious than I would by trying to refine out the gold, silver and PGM's from the junk.

SAFETY should be the main concern for anyone who wants to do reclamation or salvage. Even common metals like copper, iron and aluminum in chemical concentrations of only a few parts per billion can prove to dangerous to your health. The handling of acids of any concentration (including table vinegar

⇦in bulk on

eBay

or

Amazon [affil links] ) should be done with great care and with attention to detail. The wearing of PPE (personal protection equipment) is a MUST DO!

Secondly, If you intend to do the reclamation of precious metals from electronics, prepare yourself with knowledge. I recommend "Refining Precious metals From Waste" by C.M Hoke. Spend the money. Read the book. Do the experiments in the book to become familiar with the chemicals and procedures you will be using.

There are several methods out there for dissociating gold and silver from base metals. I will not go into them here. But the one thing I recommend is that you do your work in small batches and that you control your wastes.

Finally, do this; Treat your waste products as part of the chemical process. If you create a toxic waste byproduct, learn how to treat it and make it non-toxic before you move on to your next batch of experiments. Treat our planet like it is the only one you have because it is. Store your chemicals safely and use them with wisdom and you will enjoy a hobby that is not only rewarding monetarily but will increase your knowledge of a subject that few understand.

Regards,

Sam the Salvager

Electronics Salvager - Harleysville, Pennsylvania, USA

Q. I have a lot of gold plated aluminum with cosmetic gold plating (0.00005" nominal thickness) and in some cases electrical use plating (0.00020" nominal thickness). There is usually a very thin layer of nickel between the aluminum and the gold. Is there a simple way to remove the gold chemically?

Jim Schimer- Long Beach, California USA

November 30, 2015

Need help with exact mixtures of SMB/water Urea/water and tin/HCl

Q. Ive half assed read Hokes, I have Steves DVD. I have semi-outline drafts from 2 refiners and felt I was ready to tackle this. I took 34 grams of 14 kt jewelry and cold soaked it overnight in 36 ml nitric and 12 5ml of ccl. and inquarted 34 grams like the DVD outlines. When it comes to the part about adding urea/water they just say "add the urea and water". My question is how much of each is needed to drop the gold? Also how much HCl do I add to my Tin to get stannous chloride testing solution? And lastly how much water do I add to my SMB? Thanks greatly in advance to anyone that can help me.

Randall Langbeckergold pmg silver and diamond buyer - conyers, Georgia, USA

January 21, 2017

Q. Trying to figure out best way to separate gold plated silver contact on copper from relays. I have about 7200 of them,silver is 65% and gold is 25%; each weighs .204 grams. What is best way to recover silver and gold?

Dane beaver- Baton rouge, Louisiana

April 30, 2018

Q. Hi. My name is AJ and I buy storage unit. A lot of the time I get gold plated jewelry that I would like to melt down to remove the gold. I do this as a hobby and would like to know if there is an easy way or the proper way to remove the gold from the plated jewelry. I'm looking into investing in a melting pot. Melting the gold plated jewelry will the impurities separate from the gold or do I have to do other processes. Any help would be appreciated. Thank you

AJ Jackson- Boise Idaho USA

April 30, 2018

A. Hi AJ. We appended your inquiry to a very long thread on the subject so you can read as much or as little as you wish about recovering the gold from gold plated items.

But briefly: the gold value in most gold plated jewelry isn't much; sometimes it's more, but sometimes it's as little as $.02 to $.06. The recovery of the gold is difficult; the gold will 'alloy' with other metals, so melting it would just give you a blob of whatever metal it's made of, with a tiny amount of gold mixed into it as a contaminant; and it would make it much harder to recover the gold because it would no longer be only on the surface of the items, but 'frozen' into the blob where chemicals and electricity can't get to it. Sorry.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

May 2018

Q. Hello I am vishwajit from india, today I was planning to try extraction of gold from e-waste by aqua regia. I wish I could get brief details on what kind of solutions I need to buy in quantity and concentration point of view?

waiting for positive results

- nashik, Maharashtra, India

May 1, 2018

June 2, 2018

! Whew! It was a long journey to the last comment of this thread. But since I made it I will go ahead and share a few thoughts that remain after it all.

1) Doesn't ANYONE still precipitate with good old-fashioned ferrous sulphate any more? LOL

2) Who here hates Allen keys as much as I do?

3) You can't tell me that rolling the back of a spoon over that brown powder isn't STILL the coolest part of refining gold! ;-)

4) Word of advice: If you aren't making enough money in gold to impress your buddies, just tell them it's really all about the chemistry and show them the spoon trick. Everyone loves the spoon trick!

5) And for all of those who try so hard to convince people there's no money in refining, you might be right. However, if I said I still have a 1963 Motorola mainframe intact, bought at a Motorola auction in the early 80's, sitting in my backyard, you'd ALL be trying to figure out where I live and what my favorite chocolate is, wouldn't you?

(and BTW, yes I do and although I like dark chocolate truffles best, I like that spoon trick WAY too much to give up my mainframe!)

I loved reading all the comments!

1971 - Phoenix, Arizona, USA

Thanks Tricia :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

June 2018

Left CPU gold plated pins in acid solution too long and it dried out

Q. My situation: is that I just recently found a Pyrex Bowl full of gold plated CPU pins suspended in a muriatic acid solution that I had been working on over 6 months ago. Knowing me I had forgotten about it until now. And it looks like it has dried out somewhat. There's a thin layer of green crust on the top that looks like little tiny tiny green beads all stuck together. The middle layer is a light green watery solution and it's also foggy. The bottom layer consists of gold pins and other pieces of metal which I assume is all the pins I was trying to get the gold from as well as get rid of the alloy Metals for a pure gold content when it comes time to fire it off.

I would like to know what the green crust is and if it's too late to recover anything from this Pyrex Bowl of gold pins and muriatic acid. Or if somebody has a knowledge on how to save this that would be great and I would appreciate that information in your help.

Brandon BossHobbyist, student - Edmonds, Washington United States

July 15, 2018

Q. I've found a multitude of mid-90s motherboards and circuit boards used in manufacturing power plants and paper mill paper machine systems. There's got to be a reason the old boards were saved. How can I process all of it?

Jason Joiner- Columbiana

November 26, 2019

Q. Yes I'm into e-scrap I want to start a gov. Based Grant e-scrap. Curious as to where to apply. As well, my question is a friend owned a family operated TV repair shop for more than 50 yrs. He recently shut down and gave me more than 600 TV's, lcd plasma projection ext TV's ... so far I have seven 5-gallon buckets of boards, IC pcu chips, fingers hard drves, and still got 250 left. I'm just wondering am I wasting my time or will it benefit me? I wish I knew around about how much to expect.

T

- Pelion, South Carolina

August 8, 2020

A. Hello Jamie,

You will probably find obtaining a grant will be very difficult for electronic reclamation. Mainly because of EPA requirements. There is a good letter on this thread from Sam Kamees on the subject that I thought was very good. Scroll up to the letter dated May 15th, 2015.

- Winston Salem, North Carolina USA

August 10, 2020

Q. So I'm sure this will be added to an already going thread, but I had attempted a small experiment of hydrochloric acid & peroxide 3:1 ratio with an aquarium pump added and let it sit for 3 days on some fingers, pins, and chip powder (all separate) the gold easily came off the fingers, the pins took a little longer, and the chip powder ... well, it's still sitting in its container because I didn't know what to to with it. All were conducted in a homemade clean room with ventilation system that runs the air through water mixed with baking soda then out through the rest of the ducts. I always wore a full face p100 60926 respirator with gloves ⇦ this on eBay or Amazon [affil links] , and an apron ⇦ this on eBay or Amazon [affil links] . All acids were properly neutralized and any waste was disposed of through my local hazardous waste facility. (That can be expensive by the way).

I'm wondering if anyone will purchase what I have remaining from my experiments, or if I need to simply complete the process. If I need to complete the process, any recommendations on what to do with the chip powder? I'm being honest here in acknowledging that I started this without the full understanding of how to complete my process. I've got the Gold from the pins & fingers filtered from the HCl & peroxide soak, have rinsed multiple times with water, they are now all sitting in a filter of silk screen material waiting to be dealt with. As I said the chip powder is still in its solution.

Also on a side topic a friend of mine decided to try the vinegar & peroxide route and has his stuff still sitting in the solution after a little over a week. It appears clear-ish with a light blue tint. Any suggestions on where he went wrong and how he can get his gold out?

I wish I would have found this thread before starting my process -- it would have helped.

I am familiar with the basics of chemistry, and have all the safety gear and set up needed, I just need to know what to do next, please.

Also, I noticed that with regards to refining pm from electronics, a lot of people say sell it to a refinery,; my question is -- what do you do if you know the refineries around are only offering 30-40% of today's current value for PM? And my second question is related to the chemicals used in refining. One person had mentioned that local chemical supply companies offer classes. None of the companies around me are offering classes of any kind, they actually thought I was joking. I would like to gain more insight into the different processes involved as well as the precautions to take, but I am a hands-on or in person learner ... reading a book simply won't get through to my brain. Any suggestions as to how I can learn about this. I promise from now on its simply as a student not a practitioner.

- Anaheim. California

September 13, 2020

Q, A, or Comment on THIS thread -or- Start a NEW Thread