-----

Chrome problems plating a convex piece

2002

Hello all:

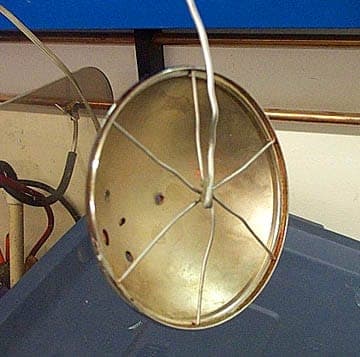

I'm a hobby plater that is having a WHALE of a time with a certain part. The part is a 3.5inch diameter convex mirror back for a old car. I am not concerned with the concave side of the piece as the mirror will cover it. The acid copper and final bright nickel went on great and it is mirror smooth. The problem is in my chrome bath.

CHROME BATH IS...

.33 oz sulfuric

33 oz chromium trioxide

1 gallon water

I do not have any adds to help the bath throw better.

TEMP.....90F.

|

|

|

I seem to keep burning/peeling the edges and getting a haze in the HCD of the middle. Am I racking the part wrong? Is my anode/cathode wrong? I'm at 2:1 maybe a little more. I'm almost inclined to thing my wash of the activator is not proper because the haze is very random and splotchy. It is a proprietary activator that has given me no problems until this piece. But.........if I plate another piece with the same procedure it comes out fine.

Any and all help would greatly be appreciated.

Thanks all,

Tom HaltmeyerT and S Wood Products - Peoria, Arizona, USA!

2002

The temperature sounds low to me. 110 °F would be more typical for decorative chrome.

If you added a gallon of water, your mix is a bit below 33 oz./gal, but I don't think that's a problem.

Be careful about trusting your intuition on where the HCD area is; I'm not so sure that the center area is the HCD area and the rim the LCD area because you report burning in the rim area and you may have incomplete coverage in the center area (although the photo seems to show a whitewash more than a lack of coverage). Visualize flux lines running from the anodes to the cathode and you may find there is actually more current around the rim even if it is a couple of inches further from the anode than the center area is.

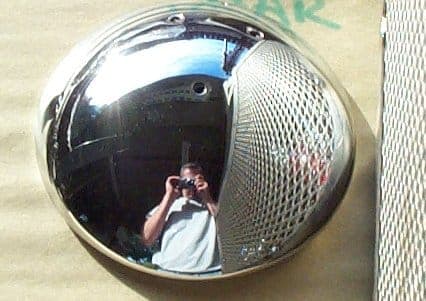

I'm surprised how well your photo came out, but a hint about photographing brightwork: try to position a wire mesh screen to reflect in your picture--it quite clearly reveals where you have haze and lose reflectivity.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Thanks Ted:

I will try the higher bath temp this weekend. I kind of thought the edges were a HCD are along with the bulge area on the mirror back. The flux line thing is very interesting, along with figuring out anode placement for parts in chrome. Quite a challenging learning experience here! Yes, the part did cover well, its just the darn hazy area. It was perfect except for that.(grumbles) :) The burning on the edges came after a few more tries. The pitted pot metal is really a blast!

Thanks for the advise.

Tom Haltmeyer- Peoria, Arizona

2002

The anode:cathode should be at least 1:1 (one side only on the each), preferably with more anode area in the center and not much anode beyond the edges of the part, plus the anode only on the side to be plated. The Temp is definitely low. 120F is even better than 110F. BUT, the plating process generates heat, so if you are plating for a long time, you may need some cooling.

At the higher heat, it will require a little more voltage to get the same plate rate. 3.5 to 4.0 volts depending on the anode to cathode distance. What is your anode made of, and what is its shape?

James Watts- Navarre, Florida

2002

2002

Just wanted to say thanks for the help on getting the chrome bath working good. It was the temp and a little finessing with the anodes.

The mirror back is about 99% perfect. Can it ever be perfect? :)

Just a personal thanks.

Tom Haltmeyer- Peoria, Arizona

James:

Looks like the higher bath temp did the trick. I was running it between 110 and 115. I will try 120 this weekend and see how things come out. I have a lot of stainless trim to plate also. The parts I'm doing right now are relatively small. (30 sqi and below) so the bath probably won't heat up too much. I'm pretty proud of it! :)

Tom Haltmeyer- Peoria, Arizona, USA

2002

Q, A, or Comment on THIS thread -or- Start a NEW Thread