-----

Fingerprint stains & corrosion, on chromated zinc plated steel surfaces

Q. A question about plating zinc + clear chromate on mild steel... Our plater ships us parts with zinc + clear chromate. If we handle them with bare hands, we leave yellow fingerprint stains. Our customer will not accept this condition. The plater doesn't know what he is doing wrong. Can anyone explain how to correct this problem. thank-you mda

Mark D. Andersonmetalworks - Mequon, Wisconsin

1999

A. The plater isn't doing anything wrong. Wear light cotton gloves when handling the parts and this will prevent the sweat attacking the surface. If your supplier can't answer this you have to ask if he really understands his process and that should start some alarm bells ringing in your head.

Dougie Lightfoot- Fife, Scotland

A. Sweat and finger oils are quite corrosive. Your plater is not necessarily doing anything wrong. We found out that one kind of hand lotion would strip yellow or OD chromate (which are a lot more resistant than clear by at least an order of magnitude) in seconds.

I would contact the American Zinc Association in Washington DC to see what their thoughts were for improving the situation. Alternative would be to contact a major supplier of zinc plating /chromating materials. The chromate is really a gel for up to 24 hours. Any contact prior to that is begging for trouble. One answer is to have your people wear clean gloves until you find a cure or at least an improvement.

James Watts- Navarre, Florida

A. There is apparently some anecdotal evidence that people who handle chromated parts are subject to an increased incidence of skin cancer. I have no information to offer either in support of this hypothesis or in refutation of it. However, considering this possibility, plus the very evident reaction between their skin and the chromated surface, and the fact that it is causing rejects, it indeed seems only reasonable that the handlers should be wearing gloves.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. Mark,

White fingerprint stain on part, try to take part out after zinc plate and see any stain; if you have stain on part nothing wrong with clear chromate --stain is something wrong in zinc plate or precleaning problem. To run Hull Cell

⇦ huh?

panel if you can duplicate stain problem run Hull cell panel.

Popatbhai B. Patel

electroplating consultant - Roseville, Michigan

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. We design a large sheetmetal chassis for optical networking equipment. It is made from Type III SC2 zinc plated CRS. All external surfaces are specified cosmetic, so need to look good. To minimize fingerprints, our suppliers wear cotton gloves while assembling the chassis. However, a few fingerprints or handprints inevitably make their way onto the plated surfaces. I have heard that acids and sweat from handling can etch the plating and eventually show up as corrosion. Sure enough, after sealing the chassis in a plastic bag with a 1/2 lb bag of desiccant and conducting environmental shipping testing (minus 40 °C/72hrs:plus 70 °C/72hrs; plus 40 °C @90-95RH /72 hours) we witnessed handprints show up as dark brown corrosion or as white "powdery" residue). The result was pretty ugly.

Questions:

1) How would I determine if this is a pre or post-plating problem?

2) Would thicker plating help minimize/eliminate this problem, Type III SC4?

3) Also, what is recommended to clean fingerprints off of zinc plated surface? I can't find anything on the web and I have received 3 different answers.

a) The plater recommends a 30% diluted solution of Windex Commercial Line

⇦ on

eBay or

Amazon [affil link]

.

b) Sheetmetal vendor uses aerosol stainless steel polish/cleaner.

c) Our contract manufacturer is used to using isopropyl alcohol.

4) Finally, what else I am overlooking.

Thanks in advance for your wisdom.

Richard Huang- San Jose, California, USA

2002

A. I have worked extensively with the electronics and telecommunications chassis industry and have developed a sure fire 3 step program to solve your problems.

1. Wear clean cotton gloves when handling and assembling

2. Handle and assemble in an air conditioned environment and or provide sweatbands and towels for the handlers

3. Lower your expectations just a little. Problem solved!

- Charlotte, North Carolina, USA

A. I'm not familiar with your spec's so this may already be covered by your question. What kind of surface treatment does your zinc plating get? I've worked with tin/zinc plating and it finger marks very easily. Do you have some kind of passivation in place? I would expect cleaning prior to plating to remove finger marks, and I can't imagine people handling objects between cleaning and plating, so I would suggest your blemishes occur post plating.

Ian Brookeuniversity - Glasgow, Scotland

A. I agree with Todd. The handling and housekeeping at the plater and the assembler are critical. I would also like to point out that many trivalent chromates (blue bright) tend to be very soft when applied for maximum corrosion resistance and handling of any kind should be avoided for these and all other chromate films for a minimum of 24 hours to allow the gelatinous chromate film to reach full hardness. Also, remember the human factor. Gloves are fine but the workers need to change the gloves when they get damp or you will just leave smudge marks instead of distinct finger prints.

For Todd: I bet Dave remembers this from his years up North.

Gene Packmanprocess supplier - Great Neck, New York

A. As one who has some 30+ years of zinc plating on electronic cabinetry and some 15 years working on various spec writing committees including both ASTM and SAE, the problem looks all too familiar.

1) Go back to your plating house and insist they use a HEXAVALENT, clear chromate over the zinc plating. They've likely gone to a more environmentally friendly TRIVALENT or non-chrome conversion coating. These have far less protection*.

2) Your burn-in temperature is beyond the upper limit for chromates. Around 140 °F (60 °C) the hydrated gel-like chromate becomes dehydrated and the corrosion resistance of the chromated zinc drops off. All standard plating specs for chromates limit drying temperatures and final hot rinses to less than this.

3) Switch to a yellow chromate which offers more protection but probably won't meet aesthetic or electrical resistance requirements.

Lastly, and I can't believe Todd didn't suggest this, switch from zinc to electroless nickel. Nickel is FAR less prone to such staining and can more easily be cleaned, even with Windex Commercial Line ⇦ on eBay or Amazon [affil link] !

Milt Stevenson, Jr.

Plating shop technical manager - Syracuse, New York

* Ed. note: Note that this posting is from 2002 and probably doesn't represent Milt's opinion of the newer trivalent processes after 2 decades of advances.

A. Now that Milt mentioned it, electroless nickel does do very well and is used in that application. Especially when some of the panels are aluminum. The electroless nickel allows for RFI and conductivity that is not possible with anodize. The steel zinc plated panels of these cabinets have been switched to electroless nickel plating for cosmetic continuity.The electroless nickel plated panels are subject to the same pitfalls as zinc plating though.They will still stain , discolor, and fingerprint if mishandled.The EN plating can be restored by the customer if needed but the customer will likely be offended at this suggestion. High phos EN will somewhat alleviate the staining problem but the customer will still find fault with the plating.

Gene, Dave says hello.

Todd Osmolski- Charlotte, North Carolina, USA

Q. No one has addressed the OP's question: How do I clean the fingerprints OFF? Not: How do I prevent fingerprints getting ON?

I've got the same problem. I think some people have naturally more acidic hands.

- Bridgnorth, Shropshire, UK

July 21, 2011

A. Hi, Richard. You can certainly try acetone ⇦ on eBay or Amazon [affil link] Flammable! or MILD detergent (dish detergent) to remove the prints, followed by isopropyl alcohol as an anti-staining rinse, since none of these, daintily used, should hurt a chromated zinc finish much. Best of luck with it!

But the idea that numerous highly experienced platers, each with decades of experience, all misread a very simple question, is the actual misreading :-(

Rather ...

"The Moving Finger writes; and, having writ,

Moves on: nor all your Piety nor Wit

Shall lure it back to cancel half a Line,

Nor all your Tears wash out a Word of it."

- The Rubaiyat of Omar Khayyam

The responders steered the discussion towards avoiding fingerprints rather than removing them in recognition that fingerprints usually cannot be removed. If the fingerprints preceded the chromate, they are under it and obviously cannot be removed without redoing the finish; if they were in the uncured chromate (the usual case), they're embossed into the finish, not on top of the finish, and can't be removed without redoing the finish; and if they sat on the finish for an extended time they probably have etched the finish and can't be removed. Sorry for the pessimistic appraisal of your chances, and good luck!

The right answer is that these days employees should be wearing gloves. If a dentist can do a root canal with gloves on, plating shop employees can do their jobs with gloves on.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Cleaning a zinc plated part with a chromate layer

Q. I have parts that are cold rolled steel that are zinc plated with a chromate layer on top of the zinc. It is my understanding than one can only use isopropyl alcohol to clean the surfaces without causing any damage to the chromate layer. Our chromate layer needs to pass a 96 hour salt spray test, so we cannot compromise the chromate layer.

I have always understood that any thinner, solvent would remove or affect the chromate layer.

Does anybody have experience with any products or new products that can be used that would not affect the chromate layer?

Manufacturing/Mechanical Engineer - Dallas, Texas USA

March 12, 2014

A. Hi Ana. The first thing to do is find out what spec you are plating to, and read whether it possibly restricts you to acetone because, if so, any other cleaner is disallowed. If you are not restricted by a spec, I have been led to believe that mild dish detergent or acetone should be okay. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Ted, thanks for your response. We are plating using ASTM B633 SC1 with clear chromate Type II (96 hr min salt spray). I do not see anywhere in the spec as to what solvents are approved to be used in order to clean the surface.

Ana Castano-Mears [returning]Manufacturing/Mechanical Engineer - Dallas, Texas USA

A. Hi again. Then apparently you may use whatever you wish that doesn't harm the chromate. Again, I suspect that mild detergent without a long immersion time, or acetone, can be used without markedly impacting your salt spray time. I've heard of Simple Green being used as well. That doesn't necessarily mean that these cleaners will clean the chromate as you wish though :-(

As you see from the postings above yours, the dirt can be under the chromate (probably unlikely) or embossed into it (likely).

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hi.

We are usually encountering late stains from our bright/clear zinc chromated items. The appearance is sort of yellowish and sometimes look like fingerprint marks. I have read somewhere in this site that handling/inspection of items should be done using cotton gloves but the reason not explained. We are usually using surgical gloves for the inspection of our items. Does using surgical/cotton gloves affect occurrence of stain?

Thanks in advance

- Philippines

June 3, 2016

A. Ahead of the bright clear chromate you need a FRESH 1/4%/vol Nitric Acid Dip.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

A. Best way is to use double handgloves when handling Zinc plated parts.

1st layer-Surgical/rubber gloves

2nd layer: Cotton gloves

Using only cotton gloves can still leave finger print mark into the plated surface as some people still have sweating of fingers.

Q. Applying IPA into Zinc plated surface will turns to yellowish but it not turn immediately.

Can someone share some recommended solvent besides IPA to clean the surface of Zinc plated part which gives more adhesion if I need to Print an artwork into surface?

June 29, 2021

MANUFACTURING ENGINEER - MALAYSIA

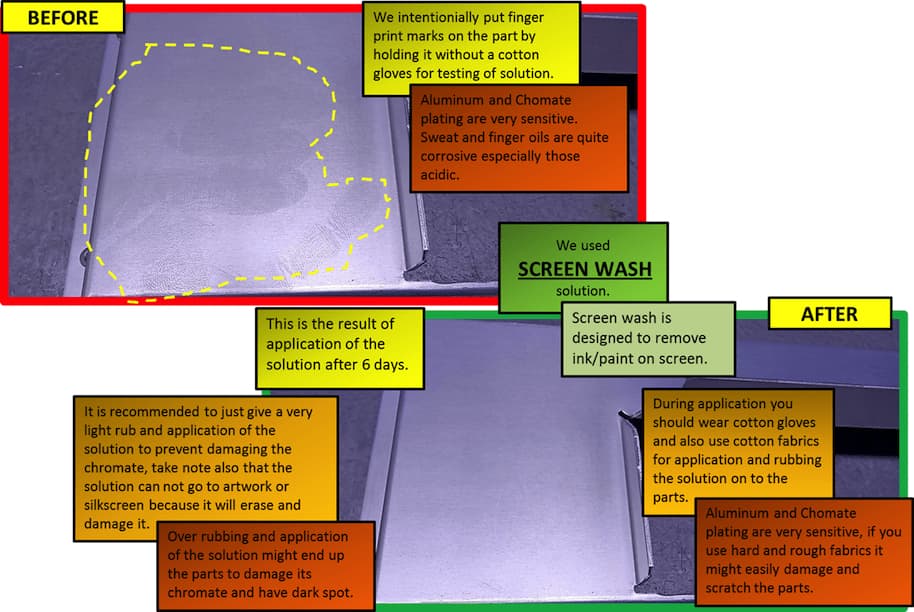

A. We are currently facing that issue regarding with our new parts & project -- except that our materials are aluminum with clear chromate/conversion. Our customer is concerned of course about the hand/finger print marks on our parts.

We tried all available solutions we have inside our company such as wipe out, thinner, retarder, etc. ... but the only solution that somehow works is the SCREEN WASH, which our subcon is using to clean their silk screens.

It surely worked!

BUT it is recommended to just give a very light rub and application of the solution to prevent damaging the chromate; take note also that the solution cannot go to artwork or silkscreen because it will erase and damage it.

Over-rubbing and application of the solution might end up the parts to damage its chromate and having dark spots.

During application you should wear cotton gloves and also use cotton fabrics for application and rubbing the solution onto the parts.

pre-qualification QA staff - cavite city, philippines

January 4, 2022

? Uh Oh, Let's start over. The headline says zinc plated steel where the chromate is fingerprinting. But the text says chromated aluminum. Which?

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

![]() Sorry Robert, I caused the confusion.

Sorry Robert, I caused the confusion.

She was not asking how to prevent fingerprint marks, she was offering help to the posters who had fingerprints on their chromated zinc plating by telling them how she removed them from her chromated aluminum. I suspect that her solution will prove applicable for chromated zinc plating -- but maybe not.

My own comment is that it's 2022, an age where my dentist does even tricky root canals while wearing gloves, and it's simply long past the time where any employees should ever be touching chromated surfaces without gloves :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q, A, or Comment on THIS thread -or- Start a NEW Thread