Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

How to Dry parts after plating, in production volume

Q. I am looking for an economical way to dry parts after plating. We are currently just blowing the parts with an air hose (shop air) this is obviously very costly and time consuming. It has been suggested that I install some kind of a conveyor system but the sizes of my parts varies considerably and my floor space is very limited.

We would would be interested in a "batch" process if any existed.

Thanks Bob

Robert Fout- Miami Florida

1998

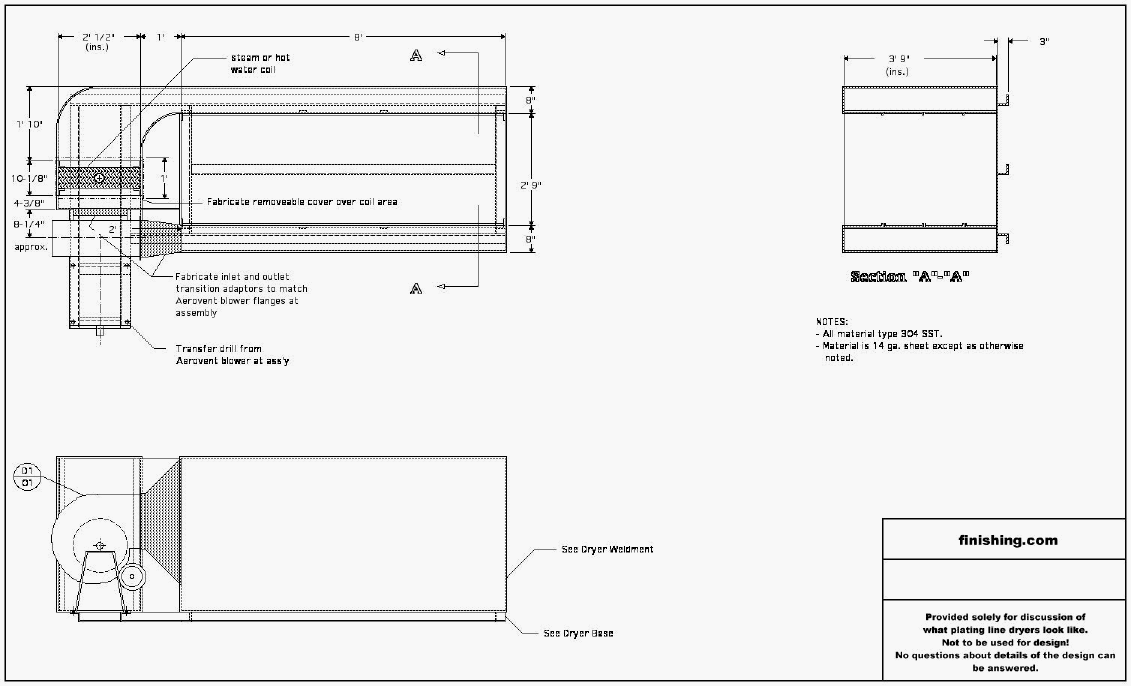

A. A 'box-type' dryer should work fine, Bob. You make an additional 'tank' after the final rinse. It has a recirculation fan and steam or hot water coils (electric or gas if steam and hot water are not available). This sketch conveys the gneral idea:

Not small, or especially cheap, but workable and efficient. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I have the same problem right now. Ted, the print being small, I did not quite understand the drawing. Are you saying hot steam will do a better job? Would a hot water (150-180 °F) tank be simpler?

Mandar Sunthankar- Fort Collins, Colorado

1998

A. Hi Mandar:

The steam or hot water is not "loose". It is contained in a coil like a car radiator. The fan pulls air past the steam coil to heat the air, then blows the heated air across the parts. The work sees forced warm air, not steam.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Thank you Ted. My observation is that if the parts surface is warmed up with hot water dip first, then blowing hot air on it is very efficient, especially if the parts are piled up. The hot surface quickly evaporates water from smooth surfaces in air, but takes a few extra seconds for threads and cavities.

Mandar Sunthankar- Fort Collins, Colorado

1998

A. `The value of heating the final rinse depends on the thickness of the parts. Very thin sheet metal parts cool back to ambient temperature in transit from the hot rinse to the dryer, whereas the drying of heavy castings benefits immensely from the hot water rinse you propose. I have a book that guides one through this theory, although I've never actually bothered to do that particular calculation :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. A trick we use is slow withdrawal from hot water, letting capillary attraction "wick" the water from the pieces as they emerge from the water. I don't remember the exact withdrawal rate, but it's around an inch per second. The water doesn't have to be extremely clean, just free of surfactants, and very hot -- close to boiling ... and the higher the surface tension, the better.

George Brackett IIISherrill, New York

1998

Q, A, or Comment on THIS thread -or- Start a NEW Thread