Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

How can I make copper turn black?

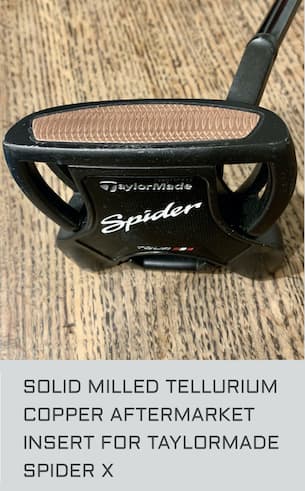

Q. I have been assembling a golf bag with only grey/black/white or silver colors. Down to the grips and shafts. The only thing holding up my completion of this project of the insert I want to buy to put into my putter. It is a tellurium copper insert and as nice as the color is, it doesn't fit with the rest of the scheme of the bag.

Q. Is it possible to stain or permanently change the color of this piece to a charcoal or ideally a black and have that finish be durable for a while?

R MunozGolf enthusiast - DFW, Texas

September 7, 2023

A. Hi R,

There are several possibilities from having the insert black nickel or black chrome plated (probably most durable), to having it professionally blackened with Ebonal or equivalent, to things you could try yourself like applying a selenium-based blackening product like Brass Black

[Brass Black on

eBay or

Amazon [affil links]

, or just using liver of sulfur

⇦ this on

eBay or

Amazon [affil links]

.

The face of the block may have a clear coat on it which must be removed, and hopefully acetone

⇦ this on

eBay

or

Amazon

[affil links] Warning! highly Flammable!

will do that.

But things wear, and coatings are surface treatments, they can't permanently change the color if the wear is severe.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

adv.: Need Black Nickel Plating?

Contact New Brunswick Plating [New Brunswick, NJ]

⇩ Related postings, oldest first ⇩

Q. I have a copper panel that is kept at liquid nitrogen temperature when used in a vacuum system. One of it's purposes is for heat removal. There are indications that copper is a very good reflector of infrared radiation and thus a poor absorber. I am looking to increase the absorbtion of IR possibly by blackening the copper. I have heard that this can be done electrolytically. Is this true? Can it also be done by wiping liquid over the surface much like blueing steel (i.e., does it come in a bottle or do I have to send out the whole panel?)?

I also have some concerns about whether the 'blackened copper' will cause great problems in a production vacuum system like outgassing, flaking, etc.

Any other comments are always appreciated.

John Davis

- Berthoud, Colorado, USA

1998

A. John,

Try an immersion blackening liquid with copper panels: 1.6 - 1.9 g/L liver of sulfur or liquid polysulfide solution at around 25 °C for 50 to 80 seconds. As long as you optimized the conditions to get the color you want, you can blacken your parts.

Good luck!

Ling

Ling Hao- Grand Rapids, Michigan

A. Dear John,

The solution offered by Ling is correct for blackening copper, however I suspect that because it is a simple conversion coating there might be problems with the adhesion, if you are looking for a coating that is black and adherent, then I would be looking towards Black Chrome Plating; provided the panels are not subjected to a lot of flexing and that the temperature can be GRADUALLY decreased, then it may work.

best regards

John Tenison - Woods

- Victoria Australia

Multiple threads merged: please forgive chronology errors and repetition 🙂

Blackening of copper

Q. I have been asked to look into ways of blackening fine copper mesh. Any suggestions would be gratefully received. Thanks.

Nick Cooper- Bridgend, Wales, UK

2000

A. Investigate the black oxide formulations offered for multilayer printed circuit board manufacturing. They are reasonably easy to control and adherent.

The real question, and not easily read from your post, is why you want a blackened copper mesh. One of the problems with answering questions here is what do you really want? The more information you give us, the better the information you get. Right, Ted?

James Totter, CEF

- Tallahassee, Florida

A. Hi, James. Yes, it's most efficient to give as much detail as possible :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Thank you I do appreciate it that the more information the better. However, the customer who would like this done is unwilling to divulge more for confidentiality reasons. I too would like to know why he want's it! Thanks again.

Thank you I do appreciate it that the more information the better. However, the customer who would like this done is unwilling to divulge more for confidentiality reasons. I too would like to know why he want's it! Thanks again.

- Bridgend, Wales, UK

A. Unfortunately it can be very dangerous if they won't tell you the application, Nick. But in addition to Mr. Totter's suggestion, you've got painting and powder coating; a half-dozen different ways to patinize either through chemical or flame blackening; zinc plating with black chromate; cad plating with black chromate; black nickel plating; black chrome plating; lamp black; black rhodium or ruthenium, PVD coatings, and our favorite finish, dipping in dark chocolate :-)

![]() .

.

When there is a need for confidentiality, one approach is to retain a metal finishing consultant and have him/her execute a non-disclosure agreement to be able to work from all the facts. If this is a food application, for example, and you apply a finish that leaches toxins ...

Good luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

|

What is the corrosion resistance of the chocolate dip for 10% white salt? Is there a difference if you use milk chocolate or dark? I really need to know. (It will be a wonderful way to get rid of some of the "unneeded" candy after next Halloween! Gene Packmanprocess supplier - Great Neck, New York A. Hi Gene! There are several idiosyncrasies with chocolate post dip. First, salt spray is not a good test since the chocolate will melt and wash away. That's bad. This leaves only the colder areas of the country where it might find any use at all. Then, chocolate is poisonous to dogs, so it can only be applied to areas which cannot be reached by Fido, or Rex, Spot, Tickles, etc. That's bad. In use around the exposed undercarriage of logging trucks, it is a ready and high calorie source of food for the spotted owl. That's good or bad, depending on how you voted in the last presidential election :-0

Tom Pullizzi Falls Township, Pennsylvania |

My lord. "How to blacken copper". Who cares why? Just answer the guy's question!

My lord. "How to blacken copper". Who cares why? Just answer the guy's question!

- Elmira, New York

May 2, 2010

Hi, Don. Please try to understand why we care:

- If people use cadmium plating processes, or patinizing process with arsenic or tellurium to filter a food product, it will poison people; they may get sick and they may even die.

- If he picks a coating of very limited life, and warrants it for 5 years, we've served him poorly indeed.

- If the screening goes behind a viewing glass, or into a solar collector, our suggestions with high vapor pressures (like paint or powder coating) can quickly coat & obscure the glass, rendering the whole project worthless.

- If he uses it in a vacuum environment, zinc coatings & cadmium coatings, and some others we suggested, will sublimate, shorting out electronics, possibly causing a tragedy.

- Several coatings we suggested are only good for 140 °F -- what if his customer uses the mesh at a higher temperature than that?

There is never a "right" finish in the abstract, just as there is no "right" vehicle in the abstract; each offers advantages & disadvantages crucial in some applications but of little importance in others. Would you recommend that I get a sports car, a minivan, or a Mack truck? And my lord, please just answer instead of asking what I want to use it for :-)

Thanks and regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I want to obtain a flat black finish on copper. This is for the purpose of absorbing heat from a radiant source. I would like to have the black coating be thermally conductive and not a black "paint" laying on top of the copper. It will not be exposed to wear so the finish does not have to be very hard. A finish that would inhibit oxidation would be great. It must withstand temperatures of up to 650 F.

Are there finishes for available that would allow me to tint some small prototype samples? Is there a disposal problem with the solutions involved? If production is needed, is this an expensive process?

- Madison, Alabama

2001

A. You need to use a copper oxidizing formulation like Ebonol from Enthone. The bath will be highly caustic and dangerous to use and poses a disposal problem since it is copper bearing. Find a professional to do the job for you!

Russell Richter- Danbury, Connecticut, USA

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. When I was in middle school we had an art class where we took a sheet of copper (I think) and wiped it with some liquid that made it turn matte black instantly. We then scraped off the black coating with a sharp tool, thereby re-exposing the copper beneath. Does anyone know how to chemically turn sheet copper black?

Thanks.

Jim V [last name deleted for privacy by Editor]- Boston, Massachusetts USA

2002

A. Quickest way to blacken copper is using a sulfur solution. You didn't say how big a piece you wish to blacken. If only a small solution is needed, you may be able to make a solution using match heads and hot water to make a weak solution. You will probably have a hard time finding sulfur or polysulfides to make a true solution. It will work better if the copper is clean prior to wiping with solution. If you don't care about surface texture, the best thing is to sand or preferably sand blast prior to blackening. The duller the sanding the flatter the finish. Leave solution on copper for a couple minutes, you may need to repeat. Rinse and dry between applications.

Good Luck.

Wayne M [last name deleted for privacy by Editor]- Mississauga, Ont., Canada

Blackening process for large copper art piece

Q. I want to "blacken" a large copper art fountain made of new, cleaned copper. Once I get a black or charcoal base for the copper, I want to highlight with a green patina, giving the piece an ancient look. I've tried Jax Black and Jax Flemish Black, applying several coats. However, the best I can come up with is a rust-color, i.e., darker brown. Is there a product or process I can use that would cover the copper in a black tone, over which I can apply green patina highlights?

Would spray-painting the copper with a matte black work, over which the green could be applied? Then wax the entire surface?

Thanks for your help!

Jurgen Ahlers- Atlanta, Georgia

2003

A. You can try with 2% solution of potassium polysulfide. Solution must be applied on torch heated object with brass scratch brush. Matte black color develops quickly, after that surface can be variegated by lightly dabbing with soft cloth dampened with solution.

Goran Budija- Cerovski vrh Croatia

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Hi,

I have the task of optically blackening (anodizing?) the inside of a copper can. I was wondering if the use of liver of sulfur ⇦ this on eBay or Amazon [affil links] ] would be sufficient enough for this purpose.

Thank you

Jairo Velasco Jr.research assistant - Syracuse, New York

2004

A. Hi Jairo. Anodizing involves application of anodic current on the item while immersed in an appropriate salt, so I doubt that that is what you are doing -- and I would not electrolyze liver of sulfur. If the question is whether liver of sulfur will cause blackening of copper, the answer is yes it will, and it's often used for specifically that purpose, but there are both better proprietary blackeners for copper (Ebonol C is an example) and better methods like black chrome electroplating or vacuum deposition of black coatings (Acktar for example). Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I have a copper table that when we purchased it which had a smeared black finish to it. My cleaning lady to a metal cleaning product to it and it cleaned off the finish and now it's just clear copper. What can I put on the top to re-create the black smeared look? It appears the manufacturer just put some liquid on it and smeared it.

Debbie S [last name deleted for privacy by Editor]home owner - Menlo Park, California, USA

2004

Q. I am in the same situation. I see that nobody has answered your question.

fred shaw- queenstown south africa

May 18, 2023

A. Hi Fred. liver of sulfur

⇦ this on

eBay or

Amazon [affil links]

is probably the most common darkening agent for copper. You could probably highly dilute it with water, and just wipe it on and rinse it off. But selenium dioxide based solutions like Brass Black

[Brass Black on

eBay or

Amazon [affil links]

and Brass Darkening Solution

⇦ this on

eBay

or

Amazon [affil links] will probably produce a darker color.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

I am a ceramic artist and want to add black metal handles to complete the work. I would like to use copper cable for some pieces and brass rod for others. What could I use, commercial or a recipe to turn these two metals to black or blackish brown.

Debra OlivaCeramic Ortist - Okemos, MI USA

2006

A. Hello Debra. We added your inquiry to one of several threads her about blackening copper, but the most straightforward answer may be that liver of sulfur ⇦ this on eBay or Amazon [affil links] will blacken copper and brass.

Luck & Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Blackening copper for computer cooling

Q. I am interesting in blackening copper parts for a computer cooling system. I do not a protective finish, simply an aesthetic one. I realize that aluminum is much easier to anodize to a black color but copper allows for better transfer of heat. I would prefer a flat/matte finish to a glossy coat. Any ideas? Also, any ideas how to give copper a more silver finish without plating it?

E. Asher BalkinCopper parts for sub-zero computer cooling research - Columbus, Ohio, USA

2006

A. There are countless patinas for copper, Asher. Please see if our FAQ on the subject is any help to you.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. You can use next solution:

25 gm potassium polysulfide

1 lit water

immerse copper in hot solution(oxide and grease free!)

Matte dip for copper:

1 lit sulfuric acid

1 lit nitric acid

2o ml hydrochloric acid

50 gm zinc sulphate

⇦ this on

eBay

or

Amazon [affil links]

5 gm soot

Add sulfuric acid to nitric (very slowly), when cold add hydrochloric acid, zinc sulphate

⇦ this on

eBay

or

Amazon [affil links]

and soot. Use rubber gloves

⇦ this on

eBay or

Amazon [affil links] and safety goggles

⇦ this on

eBay or

Amazon [affil links] ! Work outside or under strong ventilation.

immersion silvering for copper:

15 gm silver nitrate

30 gm sodium thiosulphate

⇦ this on

eBay

or

Amazon [affil links]

10 gm ammonium chloride

1 lit water

Dissolve nitrate in 50 ml water, add ammonium chloride dissolved in same amount of water, add obtained silver chloride to thiosulphate solution in 0.9 lit water.

Cold immersion!

Good luck!

- Cerovski vrh Croatia

A. For those who are looking to turn copper black go to an art supply store and ask for liver of sulfur ⇦ this on eBay or Amazon [affil links] . It will blacken copper almost instantaneously. Test on a corner or a scrap first to give you an idea as to how fast it will take effect. Also make sure your copper is not coated with a lacquer and make sure to use in a well ventilated area (the fumes are not toxic but, being sulfur, the smell is very unpleasant).

Jon HartyArtist - Coeur d' Alene, Idaho, USA

Q. I've read an earlier thread on this subject but couldn't determine the best action. I use 1/4" copper plate for electrical connections which get warm at high current. They are not for use in food processing or medical devices, rather for general industrial size rotating machinery operating in temperatures of -60 °C to +130 °C . I would like to raise the emissivity of the copper plate to improve heat dissipation at the higher temperatures without affecting circuit resistance. I was thinking of coating the reverse side only of the copper plate so that the electrical connections are not affected but I cannot find a cost effective way of achieving this. The coating should be generally durable but not necessarily impervious to minor scratches. Any ideas please?

Stephen Hartleyproduct designer - Sheffield, South Yorkshire, UK

November 25, 2010

Q. Hi, I have the same question. I have no problem disclosing the needs of the finish though. To suit my need the less reflective, with high light absorption the better. I would like to it be UV stable and last for as long as possible, 20 years or better. It would be exposed to around 150° F and possibly 200 or higher. I don't want poison gases or particles floating around the most of all! Thanks!

Michael Davidson- Dayton, Ohio, US

January 11, 2012

A. Hi, Michael.

Black chrome plating sounds quite right to me. It can be very matte & very black, and is used to line the inside of microscope and telescope tubes. The temperature is no problem. You might wish to listen to our podcast on black chrome.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Cold blackening of copper is coming out red

Q. Hi I am a chemical engineer working in electroplating freshly. I have problem in oxidizing copper with cold method (selenium). Workpiece becomes red, not black.

Please help me to make black oxidation of copper with selenium, copper sulphate, sulfuric acid; and how to make analysis of selenium.

- Alexandria, egypt

A. You might try preparing a fresh make up and checking redox potential (ORP) vs. your production tank contents.

Selenite can be tested for via redox titration with permanganate. There is also methyl orange

⇦ this on

eBay or

Amazon [affil links]

acidity to be checked.

Dave Wichern

Consultant - The Bronx, New York

January 9, 2017

Q. Hi,

I am interested in a finish I have seen others achieve on carbon golf putter heads by using black oxide. How are they able to achieve a dark black shiny/glossy finish? Many thanks

- London, UK

January 31, 2021

A. Hi David. I don't know exactly what golf club manufacturers do, but the hot black oxide process can be done directly on steel, and centers upon putting the object into boiling caustic soda ⇦liquid caustic soda in bulk on Amazon [affil link] plus nitrogen-based oxidizing agents to generate black rust on the surface. If the object was very highly polished before hand, it comes out a jewel-like blue black; if matte finished before immersion it comes out matte black. This finish is common on firearms. It is possible additionally to lacquer it or apply higher technology clear coats for other purposes.

But there are many other routes to a black metallic finish: copper plating followed by blackening, zinc or zinc-alloy plating followed by black chromate conversion coating, black nickel plating, black chrome plating, etc.

Please help us help you by telling us why or in what way you are interested -- as a hobbyist who wants to try it on a couple of clubs, a plating shop who wants to find a process supplier so you can offer this process, or a manufacturer looking to find a shop to do this finish for you, etc. Thanks!

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I want to buy this little AAA flashlight, but this manufacturer only makes it in copper right now, so I found this page because I want to know if I can blacken the light.

https://countycomm.com/collections/view-all-light-products/

From some of the methods I've read, this might pose a problem, since it's a flashlight that probably can't be immersed (not sure), so I'd like to know what others could recommend.

I know this creator thinks copper is really cool looking, but I don't. I like flat black for everything.

Please tell me what YOU would do in my situation. I'll buy the light regardless, because it's AAA and angle-head, with a pocket clip, and that's what really matters. Maybe one day he'll offer black.

https://countycomm.com/collections/view-all-light-products/products/copper-tactical-personal-flood-tpf-aaa-light-by-maratac

EDC nut, I like useful tools, even if I don't actually use them! LOL! - In the boring county in southern Ontario, Canada.

October 22, 2021

A. Hi CJ. Copper doesn't stay bright and shiny unless it's been protected from corrosion with a clearcoat, so your first job (and maybe the biggest since you don't know what the clearcoat is) is to remove it. acetone ⇦ this on eBay or Amazon [affil links] Warning! highly Flammable! or turpentine ⇦ this on eBay or Amazon [affil links] might or might not work.

After that, you could try 'painting' it several coats with artists' brushes dipped in liver of sulfur. But getting a smooth non-striated finish probably won't be easy. It's always best to practice with scrap if you can find anything similar.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Ted is correct about the clear coat.

You can scuff it up and spray some flat/matte black paint.

Detail masking on areas that don't get paint.

Re-paint as needed.

Metal Refinisher - SAN BERNARDINO, CA

Q, A, or Comment on THIS thread -or- Start a NEW Thread