Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Refinishing Gold Anodized Aluminum Building

2002

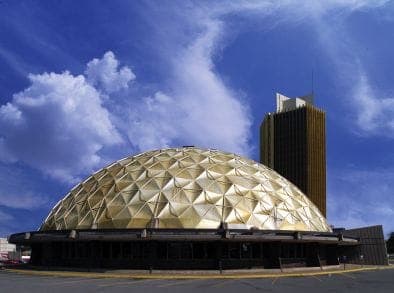

I am an architect interested in information on how to refinish anodized aluminum. In particular, we are dealing with a large, historically significant geodesic dome structure built in the late 1950's. The skin is gold anodized aluminum.

Some of the finish deterioration is due to age and weathering, but I suspect that attempts to repair leaks with acid-curing sealant may have caused additional damage. The structure is 300 feet in diameter, so it seems neither realistic nor cost-effective to disassemble and refinish. Re-anodize the metal in place is probably a fantasy, but barring that, I am also interested in any coating or paint options that mimic a gold anodized finish. The finish must be VERY, VERY convincing because this is a historic preservation project, and there is an adjacent building of the same vintage, also with a gold anodized skin that will be a direct comparison. So, what are the options out there?

Michael H., AIA [last name deleted for privacy by Editor]- Oklahoma City, Oklahoma

Assuming that the entire dome requires refinishing, rather than repairs only being necessary in small damaged areas, I would probably concede that brush anodizing a 300 foot diameter dome does sound impractical based on the sheer volume of the work compared to a brush size. However, while I don't think anybody would know the exact details without putting some study into it, I think it could be anodized in place in some manner; in times of necessity, stranger metal finishing projects have been undertaken.

You would want to start by checking some history, like what alloy the aluminum is, and whether the color came from oxalic acid anodizing, or dyed sulfuric acid anodizing, or integral color anodizing, or whatever. Once you know the process that created it, you can start evaluating the steps required for in situ anodizing.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2002

I must assume that the panels are individual pieces and were assembled on site. It would seem to me that to get the right finish, doing all the panels over would be the only way to control the finish/color. If they could be disassembled individually and replaced one by one you could accomplish what you are looking for. If possible get an original panel to start or have one made.That way you could see if the finish is correct and the project is viable. Local anodizers have reasonably large thanks to accomplish this task. I can supply some names.

Drew Nosti CEF

Member AESF Light Metal Committee

Member AAC Hard Coat Committee

Drew Nosti, CEF

Anodize USA

Ladson, South Carolina

2002

June 30, 2008

Did you take care of this project already?

I use kemp permagild.

It is the closest real gold leaf.

the panels could be zero tolerance alum with 22kt gold leaf.

they usually last 7-10 years, then the gold wears off, from the extremes. very minute gold coating on these panels.

Let me know.

nick

- strongsville,ohio-usa

Ed. note: the date was absent from the inquiry when Nick replied, but it is now inserted: 2002. So if Michael used the gold leaf paint he may be ready for a re-do :-)

Q, A, or Comment on THIS thread -or- Start a NEW Thread