-----

Hard Coat Anodize is Chipping and Flaking

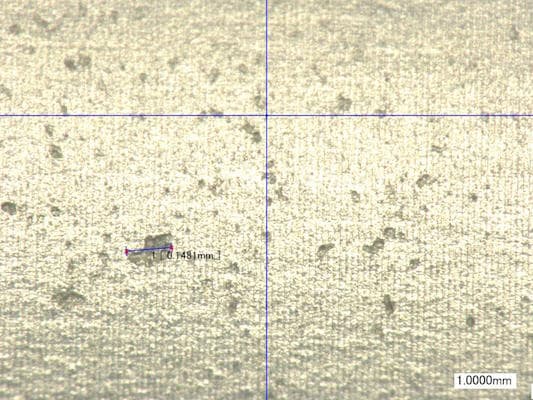

Q. We ran Type III on some parts (6061) and the parts got flakes on just one surface only; after stripping, the flaking is still there. I wonder where I should be looking for potential root causes. Please see the picture below:

- Calgary, AB

April 29, 2021

? Was the 6061 heat treated, or work hardened by dull machining?

Tell us about the deox. Look for floating soil.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

May 2, 2021

A. Jason

These parts as well as the ones shown in thread 61239 both appear to have surface corrosion which could have been generated by stacking wet machined parts and allowing them to sit for an extended period of time. The corrosion / condition would be visible prior to processing.

- Green Mountain Falls, Colorado

May 10, 2021

⇩ Related postings, oldest first ⇩

Q. We are using a hard coat anodize to protect an automotive part made from 6262 extruded. Should the anodizing chip or flake off during normal handling within the production process? Can you provide me a technical reference to support the conclusion?

Ken Tharp- St. Louis, Missouri

2002

Aluminum How-To "Chromating - Anodizing - Hardcoating" by Robert Probert Also available in Spanish You'll love this book. Finishing.com has sold almost a thousand copies without a single return request :-)

"The Surface

Treatment & Finishing of Aluminium and Its Alloys" by Wernick, Pinner & Sheasby  on eBay or Amazon or AbeBooks (affil link) A. I don't think you really need a technical reference that says hard coating should not flake off, Ken :-)  Ted Mooney, P.E. Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted is available for instant help or longer-term assistance. A. The mil spec that most hardcoat is done to, AMSA8625 or MIL-A-8625 / MIL-PRF-8625 [⇦ this spec on DLA] tells you that any sharp edges or corners should be radiused or the coating may flake. David A. Kraft- Long Island City, New York 2002 |

A. Ken,

It is not normal for the hardcoat to be chipping/flaking off, unless you are bending these parts after coating. When I have seen this problem, it normally is caused by the part getting too hot in the anodizing tank. Sorry I can't quote any technical reference, all I have is my experience (15 yrs). But if you are looking for anodizing reference books, they are available on this site.

Marc Green

anodizer - Boise, Idaho

2002

A. This is unlikely, but this happened to parts we processed long ago. It seems that an employee "discovered" that a dip in the nitric deoxidizer promoted better black dying. Naturally, the same guy figured out the if some was good more was better. Our customers were discovering that the finish cracked and compressed when they assembled the parts, and, somewhat later, that they were not retaining their color. By the time we got wind of the problem several customers had experienced problems. There may be short times during a production day when the dye needs an add or the pH is off that a short dip in nitric is a temporary fix. But that is not good practice, and we now test the lightfastness of the dye every day. Again, it is unlikely, but maybe worth looking at.

Peter Faxon- Oxnard, California

2002

Q. We currently received some parts back from our anodizer where the anodize is chipping and flaking off. The areas where the it's most apparent are on and around the edges of the parts. We have not seen this before. Is this normal? The material is 6061 and the anodize is black type III.

Dave Moskal- Loveland, Colorado

2007

Q. Can pitting in Type 2 hard anodizing on 6061T6 lead to flaking or delamination? I have a picture to share if someone could evaluate if what I am looking at is pitting.

Automotive - Findlay, Ohio, USA

September 27, 2019

A. I would like to have more info, but for now (1) it looks like the anodic film has only partially formed over thin oxide which was not removed in the deox , and/or (2) if it is heat treated beyond the alloy call out the mag and man has risen to the top and those two metals do not anodize in the molecular state but may be covered with a loosely adherent aluminum oxide.. Come on back with the specifics of the prep cycle, especially the deox.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

September 27, 2019

A. IT LOOKS AS STRESS CHIPPING; MAYBE A HEAT TREATMENT OR A SHOT PEENING WOULD HELP. GOOD LUCK.

Khair Shishani

aircraft maintenance - Al Ain, UAE

October 2, 2019

Q. Gentlemen, thank you very much for educating me on some of the possible causes or possible solutions to my concern. This aluminum piston is machined out of 6060T6 material so no post machining heat treatment is required. These parts are being supplied to me and I am trying to better understand the anodizing process and possible defects. What term should I used when addressing this condition with my supplier? Thank you

Scott Vincent [returning]Automotive - Findlay, Ohio, United States

October 3, 2019

Q, A, or Comment on THIS thread -or- Start a NEW Thread