-----

Chemical removal of heat treating scale and oxides -- steel parts

Quickstart: Inert atmospheres and/or coating the parts with anti-scale compounds, and or sealing the parts in stainless steel baggies are preferable to having to remove the heat treatment scale, but this discussion covers those chemical methods as well.

Q. Looking for suggestions on removing heat treating scale from carbon steel parts prior to tempering and subsequent grinding. Would be interested in any experience with commercial products, or "home-brewed" pickling solutions. Thank you.

Fred Pickard- York, Pennsylvania

2002

A. I would like to suggest electrocleaning the workpiece. It is the reverse from the electroplating process, causing the dirt on the surface of the workpiece to fall off.

Hartarto Ciputra- Surabaya, Indonesia

A. There are dozens of approaches and formulas. Some based on galvanic phenomena, some based on chemical attack (either highly acidic or heavily chelated), some based on the reducing potential of melt or fused salts. It depends very much on budget, type and volume of work and established facilities. Get a good book on the subject. A web search, no matter how thorough, will never be a substitute for a good specialized book. May I suggest to you the ASM Metals Handbook ⇦ this on eBay, Amazon, AbeBooks [affil link] .

Guillermo MarrufoMonterrey, NL, Mexico

A. I will suggest a 3 in 1 degreasing solution before tempering; this will remove scales and oil.

Harish Chitkara- Madras, India

H-13 got scale during heat treatment despite stainless foil wrap

Q. I heat treated H-13 with stainless foil wrap

⇦ on

eBay

or

Amazon [affil link] . When I finished heat treatment, there was scale and it's hard to remove with sandpaper. Is there a chemical solution for this?

Thank you,

student - Fayetteville, Arkansas, United states

2004

A. We've used hot alkaline cleaners for removing that kind of scale, and sometimes it even works. Pickling in hot, dangerous hydrochloric acid can also work, but I don't recommend it: you might remove the scale, and cause the part to crack from hydrogen embrittlement. Since you noted you're a student, I'd start with Naval Jelly or other rust remover that you get from a local hardware store. Those are usually alkaline based, so it should be safer than other formulations I can imagine.

Yet we've found the best thing is to keep it from happening in the first place. Something we've had really good success with is filling the foil pouch

⇦ on

eBay

or

Amazon [affil link] with a slow stream of nitrogen or argon, which displaces the air and keeps the parts bright and shiny. It's surprising how little you need, and bottled gas, especially nitrogen, is not expensive. Compare it to chemical cleaning, and prevention is cheaper than cure. By far.

Good luck!

Lee Gearhart

metallurgist - E. Aurora, New York

2004

A. naval jelly ⇦ on eBay or Amazon [affil link] is basically phosphoric acid in a jellied alcohol media. I did many types of tool steels with the SS wraps ⇦ on eBay or Amazon [affil link] with very very little staining. The secret is to eliminate as much air as possible by folding or collapsing the wrap so there is very little air and then sealing it with a triple fold pressed as flat as convenient. Lee's nitrogen suggestion is very workable if you seal the baggie well.

James Watts- Navarre, Florida

2004

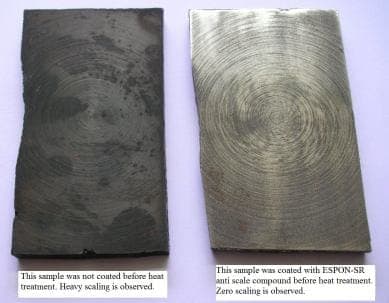

A. For eliminating or substantially reducing scaling, anti scale compound may be used.

Removal of anti scale compound after heat treatment is easy, and surface finish of component is good. Unproductive work of scale removal is either eliminated or substantially reduced.

Srikar Shenoy

- Mumbai, India

June 21, 2011

Multiple threads merged: please forgive chronology errors and repetition 🙂

Removing heat treat scale from 4140 steel parts

Q. I need help in removing heat treat scale from steel gears made of 4140. These parts are induction heat treated and are hard on outside and soft on the inside. Currently we have been vibe deburring them. With this process we are seeing damage that we cannot live with, mainly from parts banging into one another. I am looking for a process that will remove the heat treat scale with little to no damage to the part.

Thanks in advance.

Automotive - Portland, Oregon, USA

2004

A. Have you considered chemical methods such as acid cleaning/pickling?

Toby PadfieldAutomotive module supplier - Michigan

⇦ on eBay or Amazon [affil link]

A. Lots of possibilities:

1. Fixture them in your vibe so they don't bang each other.

2. Pickle in inhibited HCl, but be certain to bake after.

3. Alkaline Derust hot.

4. Glass bead blast.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

Heat treatment scale removal before plating

Q. Part material SAE 1070, heat-treated at 600 degree for 3 hours nitrogen furnace. Trying to remove heat-treated scales using 50% HCl for 20 minutes. Result: still can see scale on surface. For further process like Electroless Nickel, fail bend test.

Is there any other ways of improving the pre-treatment etching? Or is there a problem when only using soak clean as only cleaning process?

employee - Malaysia

2005

A. Even though it is a high carbon steel, you should not be seeing scale if your furnace were working properly. Just flowing nitrogen in a furnace does not remove all of the oxygen, and certainly not at once. It is better to prevent the scale than to try to remove it afterwards. I would try to find a good consultant. The MFG of your furnace might be able to help you with a better operation cycle or help to reduce leaks.

James Watts- Navarre, Florida

Removal of scale and soot before phosphating without using acid

Q. We phosphate a part after heat treatment. We would like to remove the soot and scale on the parts prior to phosphating. Since the volume of parts is huge we need a fast method of removing them without affecting the dimensions of the part.(HCl changes the dimension).

These parts have close tolerances and we need to phosphate close to 2500 parts per day. Approximate part weight is 75 g.

- Chennai, India

2006

A. You should look at a Phosphoric Acid based pickling process which will not attack the steel. Or try shotblasting.

Khozem Vahaanwala

Saify Ind

Bengaluru, Karnataka, India

A. Are you sure the acid is the problem? It appears to me that your problem is the heat treat scale is too thick. Any method to remove it will affect your close tolerances. Consider a controlled atmosphere furnace. Another option would be a vacuum furnace (absolutely the best but more expensive).

Guillermo MarrufoMonterrey, NL, Mexico

2007

How to best improve our pretreatment cleaning process?

Q. We are a small plating shop located in the Midwest. We are currently having problems w/ the pretreatment cleaning of our steel parts. We don't have trouble w/ the oiled steel parts coming in to plate. We do struggle periodically w/ the mill scale and heat treated steel parts in our pretreatment cleaning. We are a non-cyanide alkaline zinc only plating shop. We offer a trivalent blue chromate and a hexavalent yellow chromate conversion following plating. Our process for the rack line is as follows:

-Heated soak cleaner 170 °F for 10-15 minutes

-1 Rinse

-Electrocleaner (ambient temp) 70 °F 5-10 minutes

-1 Rinse

-Heated Sulfuric acid w/ agitation 100 °F (30% concentration) 10-30 minutes

-1 Rinse

-Plating tank non-cyanide alkaline zinc , maintain chemistry as follows, zinc 2.0 oz/gal and KOH level 19-20 oz/gal 12-20 minutes, pending parts and customer specs, usually 5-15 microns for thickness

-1 Rinse

-Blue/ Yellow Chromate conversion pending customer preference and spec.

45 sec -1min30sec

1 Rinse

Other relevant info

No agitation other than the acid tank

No filtration other than the plating bath

No heat on any tanks except soak cleaner, acid, and final rinse

No heat for drying/curing off line

My question is, on a limited budget, which aspect of improving the pretreatment cleaning process would give us the best value for the money? Obviously we have several areas that are already identified as problems in the cleaning process. Is one solution better than the other?

Plating Shop Employee - Cedar Falls, Iowa, USA

2006

A. Hi Chris,

Sulfuric acid is very common for removing mill scale. For heat treated and weld steel you may want to set up a small pilot tank with the following mixture:

18% by volume of 70% nitric acid

6% by weight of ammonium bifluoride

2% by volume hydrochloric acid

Temp. ambient

Time 15-20 minutes

If your parts are small enough try it in the lab, or in a 5 gal. bucket. As far as reactions the solution will only produce a mild exothermic reaction. Another option would be using HCl with an inhibitor to avoid attack of the steel. good luck!

process engineer - Malone, New York

A. Hi Chris,

The question of which process improvement will give you the most value is one that only you and your company can answer. Here are some suggestions.

1. Make sure that your alkaline cleaners are properly formulated to handle the types of soils that you encounter. Your chemical supplier should be able to help you.

2. Add agitation to the soak cleaner and electrocleaner.

3. Add heat to the electrocleaner. Higher temperatures will allow this product to do its job better.

4. Ask your chemical supplier about a formulated product in the pickling stage. This may help with the removal of the scale that you mentioned.

- Naperville, Illinois

A. Try using a pickle tank after cleaning. This is the best way I found to remove heat and mill scale.

35% muriatic acid / 65% water

room temp

You may still have to do a little wire brushing or scotch brite rubbing.

Keep this tank covered when not using. It will rust and corrode everything around it.

You will have to re-clean parts after this process before continuing into plating.

- St. Louis, Missouri, USA

A. Also we have found a really good substitute for acids. It is an acid salts from Enthone Actane 340 is the name it is used a lot in place of the HCl. The ratio we use is 1 pound per gallon @ room temp. It can be heated. Also no fumes. This may be something to try.

William Sklavenitis- Canton, Ohio, USA

2006

Q. We are faced with a problem of smut on heat treated fasteners after pickling. Is there any way of removing this smut?

A PrabhuPlating shop employee - Chennai, Tamil Nadu, India

2010

Hot scales re the chemical

Sk raja- Chennai Tamil Nadu

December 16, 2023

? Sorry SK, I don't understand your question.

Please introduce yourself and your situation with a paragraph rather than a sentence fragment. Thanks :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hello,

1. We are doing Phosphating on clutch plates.

2. The plates undergo heat treatment followed by oil quenching which forms a thick black crust on the parts.

3. Is there some way of removing this crust prior to plating using purely chemical means?

4. We use a Phosphoric-citric dip followed by glass bead blasting, but that is not feasible due to the high volume and propensity of the clutch plates to bend under the pressure.

Any insights are welcome.

Sincerely

- Anand, India

August 8, 2014

A. Try sand blasting or shot blasting.

Mohan Vishshwakarma- Jabalpur MP India

May 16, 2016

Q. Sirs,

We are doing descaling process after heat treatment for removing carbon scale on the child parts. In the process we are using saw dust and mesh powder. Is any new concept process available with low cost? Kindly share.

- Coimbatore, tamilnadu, India

August 30, 2016

A. Hi Sundara. I think this page introduced a whole bunch of excellent ideas for your consideration. I think at this point the ball is probably in your court for you to ask detailed questions about the many ideas that were suggested. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

August 2016

Q. Will a warm citric acid pickle clean the surface of parts made from SAE 52100 steel heat treated to 58-62 Rc in order to remove the residual oxides left over from the oil quench. The production parts are small -- approximately 1/2 inch in diameter and no longer than 5/8 long. Our surface cleaning task is in preparation for a PVD coating process (400 °F) to not contaminate the PVD vessel. I have a plating vendor that can do normal acidic pickling which I assume will require a post pickle bake to prevent hydrogen embrittlement. If needed I have glass bead shot blast available. The purpose of a single step of a citric acid pickle is based on economics.

Mike Gordontools - Fraser, Michigan, USA

February 12, 2017

A. Mike,

I would say "probably", but you should be able to prove it one way or the other rather easily.

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

Prevent scale build up during induction heating

Q. We are currently experiencing scale build up on our plain carbon steel bars that are going through the induction heater. Anyone have any ideas on how to reduce or eliminate this scale build up?

David Krech- Murfreesboro, Tennesseee USA

October 17, 2018

Q. How to do descaling for small parts like nails and needles which gets blackish color after heat treatment process. Kindly share an economical method for bulk production process.

Pal Singh- Pune Maharashtra

December 7, 2020

A. Hi Pal. We've posted your inquiry but I'm not sure what will be added after 18 years and dozens of previous suggestions. If you cannot afford to use an inert gas furnace to prevent the scale, but the production is too high to bag the nails & needles, and anti-scale compounds can't practically be applied, you'll have to chemically remove it as suggested. But depending on how hard the components are, hydrogen embrittlement could be an issue. Maybe try specific some followup questions in response to one of the earlier suggestions?

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

December 2020

Q, A, or Comment on THIS thread -or- Start a NEW Thread