Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Electropolishing of silver

Q. Hello, and thanks in advance for any advice about electropolishing that you can give.

My partner and I run a small jewelry company in Mississippi (www.Xover0.com) We work primarily in 925 Sterling Silver. As you can see, we have some nice inner-geometry intricacies going on, for which we could use electropolishing generally. However, we are about to do a piece which for which our mechanical finishing just won't work at all.

We've tried piecing together an electropolishing setup. We started with this video, which is for Stainless:

After reading as widely as we could and getting advice from a chemistry prof (this is not his area of expertise) we figured out how to use commercially-available 37% sulfuric rather than 95% concentrate which we can't get.

So our electrolyte mix was 108 ml battery acid

⇦ this on

eBay

or

Amazon [affil links]

, 292 ml phosphoric acid 85%

⇦ this on

eBay

or

Amazon [affil links] . In other words, we have a mix that is 62% phosphoric, 10% sulfuric, and 28% water. Early reading also told us to put a MINISCULE amount of thiourea in (about 1g / l) but we've since found out that this is bunk and are now running 20g / liter.

Having nowhere else to start with the electrical side, we started with that guy's voltage / amperage settings. And basically dissolved a piece in our mix. So we bumped back down to as low as 0.16A and 2v, as high as 4v and 0.4A. We can notice the pitting getting worse faster at the upper end, but it still doesn't work at the lower end. We still get pitting even at 0.2A and 2v, in as little as three minutes.

We've tried both a large and small titanium cathode, the anode connected to the piece is a titanium rod. The distance between is typically around 2". We're agitating the mix and running between 50 and 70 °C in all cases.

We have heard that adding glycol as a thickener can help, but we haven't tried that yet.

We would love any advice you guys can give on a good electrolyte mix and electrical settings (and temp if it's a big difference maker) for successful electropolishing of 925 sterling. Thank you in advance, and thanks for what is clearly a committed bunch of experts and enthusiasts in finishing - keeping human expertise on an internet where that is dying by the day!

- Starkville, Mississippi

November 10, 2024

Tip: This forum was established to build camaraderie among enthusiasts through sharing tips, opinions, pics & personality.

The curator & some readers who publicly share their info will be less likely to engage with those who don't.

A. Hi Duane.

I think the best approach would probably be to search for vendors of electropolishing solutions because they may have experience in attempting various electropolishing solutions for sterling silver. Alternately, you might contact Anna at Russamer Lab [a finishing.com supporting advertiser], a firm which develops and then licenses specialty formulations (they may already have a solution for electropolishing silver).

Please see also thread 0182, "Chemically polishing, electro-polishing, or 'bombing' silver", which discusses not only electropolishing of silver, but alternatives to it. I think it's important for you to identify for yourself exactly what you are trying to do before putting a name on it because I'm not sure if you are simply looking for brightening or whether you actually require the things that electropolishing does, like removal of asperities.

If you simply need brightening, something like Sparex

⇦ this on

eBay

or

Amazon [affil links] may be easier and more practical than electropolishing. If you need electropolishing, look into Gwynne Edson's patent discussed on that thread.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Two Russian cyanide-free formulas for electropolishing silver/silver alloys:

No 1.

boric acid.......20 gms

ammonia (0,88 gms/lit).....8-12 mll

water.....................400 mll

18-20 °C temp., 200-250 A/dm2

No 2.

hydrochloric acid............200 mll

ethyl alcohol................700 mll

glycerine.....................10 mll

1,5 A/dm2,20 sec.

According to I.H.Halilov: Galvanotehnika dlya yuvelirov (Electroplating for jewellers),Saratov 2003.

Hope it helps and good luck!

- Cerovski vrh Croatia

December 3, 2024

⇩ Related postings, oldest first ⇩

Q. I'm looking for an electro-chemical polishing bath (composition or commercial) available for silver?

P. Berger- Netherlands

1998

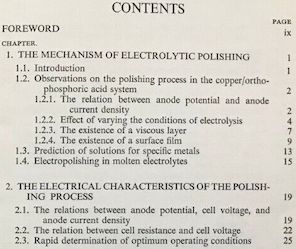

A. Graham's Electroplating Engineering Handbook ⇦ this on eBay, AbeBooks, or Amazon [affil links] gives two patents for commercial methods for the electropolishing of silver, both potassium cyanide baths.

- U.S. Patent No. 2,416,294 assigned to Arthur D. Little, Inc.

- U.S. Patent No. 2,610,143 assigned to Oneida, Ltd.

Tom Pullizzi

Falls Township, Pennsylvania

Q. What commercial processes are available today, and from whom, which will allow extremely fine polishing (finishing) of silver coating down to several microns? An Israeli firm is seeking info on deposition technology to avoid waste when applying a silver coating to a surface that is not smooth to very high standards (by microscopic analysis). Current electropolishing is not to a satisfactory level and more stringent standards are desired for implementation. Any suggestions would be appreciated.

and Chemical Polishing

of Metals in

Research and Industry"

by W.J. Tegart

on eBay or

AbeBooks

or Amazon

(affil links)

- Israel

1998

A. Hi, Avigdor. In addition to Tom's response, you may wish to see topic 0182, which deals with chemical polishing of silver, and cyanide-peroxide "jewelry bombing" (as well as electropolishing).

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Need Electro-glo 200

Q. I wish to electropolish precious metals, mainly silver. A product called Electro-Glo 200 has been recommended, but I can't find the Electro-Glo Company, which was in Chicago. If they're still out there, I'd like to know.

Alternatively, is there another product I could use?

Nelson D. Durie- Ottawa, Ontario, Canada

1999

A. Hi Nelson. I see the claim that "ELECTRO GLOTM 200" is a product of Dow, but only available in Australia & Southeast Asia, according to www.dow.com/product-line/electro-glo--electropolish/product/electro-glo-200/ ⇩.

But there is also a company in Illinois, Electro-Glo Distribution Inc., which offers electropolishing chemicals. So maybe the situation is that Dow handles their distribution in Australia & Southeast Asia? Good luck

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ed. update Nov. 2024: A search for Electro-glo on the Dow website now comes up empty.

Will silver etching, electropolishing, or electroplating work best?

Q. Hi,

The problem is as follows: the composite silver-ceramic material is produced in the form of the tape, so that the silver sheet is enclosing the ceramic material. This material is then rolled. Could anyone give me a suggestion as to how to remove the silver surface, and in the same time to preserve the grain boundaries? So that the texture measurements could be done on the interface Ag-ceramics, or only the ceramics.

Etching with the mixture of NH4OH and H2O2 is too violent, rendering pitted surface, NH4OH and HNO3 is producing the same result; electropolishing is not working with complete damage to the Ag surface. Mechanical polish is not working due to the extreme softness of the silver. I was wondering whether the electrodeposition would work?

Thank you,

Predrag Kisa- Pittsburgh, Pennsylvania, USA

2001

How do I electro polish sterling silver charms?

Q. I have been told that we do not need to polish our sterling silver charms by hand but should be able to use electro plating and furthermore believe it is fairly simple to build a small system for ourselves - is this right? Help, we are not very techie and would appreciate some advice.

Regards,

animal treasures - pet related giftware - Woking, Surrey, England

2006

A. Hello John. We appended your inquiry to a thread on the topic of electropolishing of silver, which hopefully may get you started (although a vibratory, tumbling, or other mechanical approach may be better).

But remember that as far as piloting of aircraft is concerned, flying a Cessna is simple, and as far as surgery is concerned, an appendectomy is simple -- but nothing is easy and trouble-free for the inexperienced. While you can install a silver electropolishing system, there are enough operational problems, learning curve issues, and safety & environmental concerns that the easier way is probably to farm the work out to a jobshop in that industry. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Polishing silver with least effort at home

Q. I am looking for a way to polish a lot of silver with minimal effort (not interested in Brasso and elbow grease). Being an engineer, I would like to try electropolishing, yet I have no information on how to do it or even if it would work. Can you direct me to this information? Or maybe you know of a "Handyman" method to do it at home?

Jason Cook1998

A. Hi Jason. This thread primarily addresses industrial electropolishing, which involves smoothing the surface by dissolving away the asperities. But I have the impression from the fact that you want to do this at home, that what you are looking for is electrolytic tarnish removal. Please see topic 4785 "Polishing Silver with Aluminum Foil and Washing Soda" which covers the simple technique of laying your silverware on an aluminum surface in a conductive solution. Good luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q, A, or Comment on THIS thread -or- Start a NEW Thread