-----

Electropolish problems & solutions

Q. We are having a aesthetics problem with a part we are electropolishing. Our process is as follows: We blank a disc from 301 stainless that has a hem around the edge. The hem is closed to within .002. The die uses a water based lube that is washed off in a spray washer after the part is blanked. There are a few spots on the part after wash that are either water/detergent. The part is then warped to form a bow. Next, the part is wiped off with rubbing alcohol to remove any contaminants. The part is then placed in an oven and heat treated at 600 degree F for one hour. Following the heat treating, the part is electropolished. The supplier is not willing to work with us on the problem, but what we are seeing is a hazy, film that looks like someone wiped the part. The last steps of the electropolish process are boiling in a alkaline bath (to remove acid), rinsing for two seconds and then wiping with Windex Commercial Line ⇨

by hand. Could the wiping at the end of the process be causing the hazy look? Also, prior to the heat treating, do the parts have to be free of any contaminants or are we wasting our time cleaning when the electropolish process would eliminate any spots. Lastly, some of the acid leaks from under the hem and appears to continue etching of the base material. Would extended rinsing of the part eliminate this? The part is rinsed for 3-5 minutes after acid dipping.

- Versailles, Ohio

2002

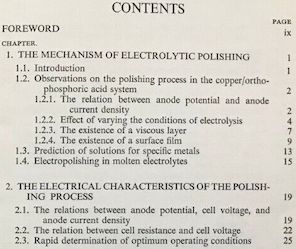

and Chemical Polishing

of Metals in

Research and Industry"

by W.J. Tegart

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi Rocky,

The skirt is a problem with only .002 clearance. Getting the acid from under this lip may be hard. Putting the part into hot caustic to neutralize the acid is probably not a good idea. What will happen is that insoluble precipitates will form in the skirt area and these will be very difficult to wash out but will seep out over time.

Two seconds rinsing for a part with this configuration is not going to do the job, no matter how you do it.

I would suggest ultrasonic cleaning after the electro-polish. This will increase the diffusion rate in the lip area and will make it possible to remove all the acid in a reasonable time.

As to why your parts are foggy that is difficult to say and I would have to run a few parts to be able to evaluate this.

If it is necessary to wipe the parts with Windex to make them look good then there is a post electro-polish cleaning problem. This should never be necessary with electro-polished parts.

Your question about cleaning the parts prior to heat treat. You are doing the right thing. Remove all contaminants that you can. If you leave them on you may end up with etching of the surface during the electropolish.

I hope this helps

- Elkhorn, Wisconsin

Q, A, or Comment on THIS thread -or- Start a NEW Thread