Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

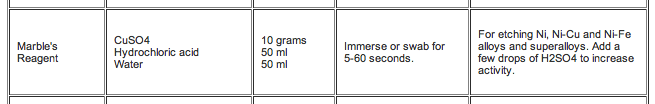

Marbles Reagent Procedure

Q. I would like to know if there is a procedure for etching steel with a marbles reagent. We have the formula but we do not know if the parts are dipped (and if so for how long) or if you apply current (forward or reverse).

David Crocker- Valencia, California

Courtesy of Pace Technologies (http://www.metallographic.com/Etchants/Etchants.htm)

A. Hello David!

We swab our metallographically prepared stainless steel mounts with Marble's etch, using the guidelines found in ASTM E3 on Preparation of Metallographic Specimens, and ASTM E407, Microetching Metals and Alloys. We don't use electrolytic enhancement.

Good luck!

Lee Gearhart

metallurgist - E. Aurora, New York

A. We typically cotton swab our stainless steels for 10 - 20 seconds with marbles reagent. We use your typical swab but with additional cotton added from a cotton ball to make it larger. We thoroughly soak the swab and try to cover the entire surface as quickly as possible. We observe the reaction and continue swabbing as required. When the etch appears to be satisfactory we immediately rinse with distilled water. You can also immersion etch but this makes it more difficult to observe the process.

Hope this helps further.

Craig

- Greenwood, Indiana

October 7, 2009

Etching Monel using Marbles reagent

Q. How long we should etch Monel(NiCu7) with Marbles reagent for revealing its microstructure?

VIPIN V PAVANANResearch project - VELLORE, TAMILNADU, INDIA

August 20, 2013

Q, A, or Comment on THIS thread -or- Start a NEW Thread