Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

Thread 101/56

Aluminum Compatibility with D.I. Water: Anodizing vs. Chromating, or Other?

Q. I am looking for a surface finish to put on aluminum that will protect it from deionized water.

Joe Solloch- Port Washington, New York

2001

publicly reply to Joe Solloch

A. There are a few different ways to protect the aluminum. You could use a chemical conversion such as a gold Iridite, anodize it, anodize with teflon impregnation, anodize then teflon topcoat it , or just teflon it.

Josh SonjuSonju Industrial Inc. - Kalispell, Montana, USA

publicly reply to Josh Sonju

adv.

Joe,

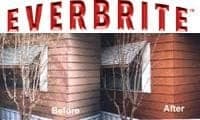

Everbrite Protective Coating is an easy to apply, non conductive, clear coating that will protect the aluminum from deionized water as well as U.V., salt air and other damaging elements. It can be sprayed on, dipped or simply wiped on. The dry film is thin and will remain flexible.

Hope this helps,

Everbrite Coatings

Rancho Cordova, California

publicly reply to Teresa Sedmak

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Will simple anodized aluminum be compatible for use with deionized water? If not, what would protect the best?

Ronald Adolphhydraulic filters - Sturtevant, Wisconsin

2001

publicly reply to Ronald Adolph

A. If aluminum is the material of your choice, "anodized aluminum" is the best for use in DI water. Chlorine in water is not good for anodic oxide film.

Timur Ulucakaluminum extrusions & finishing - Istanbul, Turkey

publicly reply to Timur Ulucak

A. You also need to seal the same to become totally resistant to the water as well.

H.KHATAU- Bombay, INDIA

publicly reply to H.KHATAU

Multiple threads merged: please forgive chronology errors and repetition 🙂

Chromate reaction with deionized water

Q. My company manufactures avionics equipment that uses chromated aluminum heat sinks and hardware that is mounted to printed circuit boards (PCB). I have been trying to determine the sequence for fabrication for our circuits and have seen that the yellow chromate finish appears duller following a deionized wash cycle to clean flux from the circuits. My questions are: What is happening to the chromate material? and if "washing off", can the material plate on electronics or fiberglass of the PCB? Is the aluminum still protected?

Steve Kleinhardtavionics - Chicago, Illinois, United States

2003

publicly reply to Steve Kleinhardt

|

|

A. First, I do not know, but from several years of applying the chromate, I would expect some of it to dissolve in DI water as it is a wonderful solvent. You might also be getting some reaction of the chromate with the dissolved flux. I will guess that you are OK if you still see a uniform yellow. Salt spray or some other accelerated corrosion testing will be a better indicator of it being OK or not. This also is "relative" and means virtually nothing until the corrosion testing is referenced or benchmarked against your real life use. I would assume that this process is a relative standard in your industry. I also assume that you are letting the chromate set for 24 hours before working with it. This allows the bulk of the moisture in the gel film to evaporate and "set". James Watts- Navarre, Florida publicly reply to James Watts A. Sounds like the "de-I water" contains chlorides which is a frequent occurence when the resins are not properly washed. The film that wipes off will not plate out onto your other electronics or plastics. The aluminum is still protected but not as much as before the deI wash. Incidentally, you mentioned "heat sink", well, guess what, the chromate deteriorates above 140 °F.  Robert H Probert Robert H Probert Technical Services Garner, North Carolina  publicly reply to Robert H Probert |

Q, A, or Comment on THIS thread -or- Start a NEW Thread