Metal finishing Q&As since 1989

-----

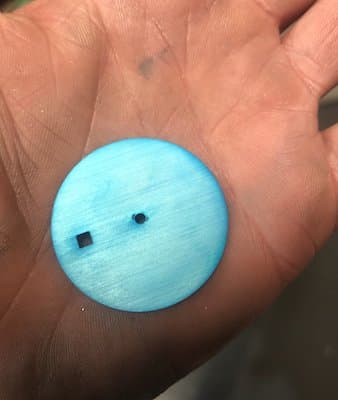

Can't Get Anodized Aluminum Watch Dials Blue Enough

Q. I'm having issues with one particular colour with making some watch dials. It's a turquoise blue from Clariant. No matter what I try I can't get a deep enough colour as compared to other colours and I'm using the exact same process.

Things I have tried;

1. adjusting length of time in dye

2. made the dye concentration higher.

3. raising & lowering the dye temperature to either end of the manufacture's specs.

4. increased the time in anodising anodising tank to have a thicker layer.

5. checked the pH of the dye tank found it to be low and increased it to around 6.

6. brought a new batch of dye thinking the old one was an issue.

7. go bald and grey

8. made a cuppa tea

- Worcester UK

May 2, 2022

A. Hi Gavin. We all immediately realize that no matter what adjustments you make to your green dye or your gold dye, neither one can ever produce the shade of blue that you are looking for. Unfortunately it's also possible that no matter what adjustments you make to your blue dye, it will not produce the shade of blue that you are looking for either :-(

But if it's not "deep" enough, i.e., it's too pastel, i.e., it's not saturated enough, it can be the case that the anodizing isn't thick enough, the pores aren't "deep" enough to absorb sufficient dye.

So I'd re-focus on item 4 in your list. Pastel colors can be obtained with perhaps 0.0001" of anodizing, whereas black can usually not be achieved with less than 0.0005"-0.0008"; so if you're looking for a rich, deep, dark blue color you may need to not just tweak the thickness a bit, but to at least double it. Do you know your alloy and your anodizing thickness?

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Gavin

Ted shared a lot of great info. I do have an additional thought or two to piggy back on Ted's input. When checking the alloy you are using, as an example you may struggle to achieve more than .0002" thickness (sorry i am not a metric guy) on your parts if you are using a 2000 series alloy. Another thought I would add is are you sure you are using the correct dye color? Is it possible that the blue you are using is not capable of giving you the depth of color you are looking for, and you need to change it? Have you been using this particular dye in the past and now you are encountering this color match issue where in the past things were fine. Are you matching someone else's color? Are you on a fact-finding mission because you are newer in the anodize field and trying to sort things out for yourself? Your plate is really full but for now I would add just enjoy that cup of Earl Grey as you are sorting this out. Also we are here to help.

supervisor - Cicero, Illinois

Saporito Finishing Co.

combo magnetic & eddy-current coating thickness tester

on eBay or

Amazon

(affil links)

A. I'm betting a cup of coffee (not tea) and a crispy creme your thickness is very lite. You need a minimum of .4 and preferably .5-.7. Get an eddy current thickness meter and check it. And when I'm right email the coffee & donut

Drew Nosti, CEF

Anodize USA

Ladson, South Carolina

Q, A, or Comment on THIS thread -or- Start a NEW Thread